Are you building a siding or a yard? Or are you in the process of planning an N scale layout but not sure what turnouts are available? This N scale turnout roundup should help to answer some questions you may have.

Turnouts (also referred to as switches) are pieces of track that allow a train to switch between two or more tracks. They are used in determining the route that a particular train will take and can be manually lined (or switched) or controlled remotely. In the most basic form, these pieces of track work the same in real life and on our train layouts.

These turnouts are designated a number depending on the length-to-width ratio of the frog (the point where two rails separate). A No. 4 turnout requires less length for the tracks to split than a No. 6 and so on. To learn more about turnouts, check out this article about the basics of model railroad track.

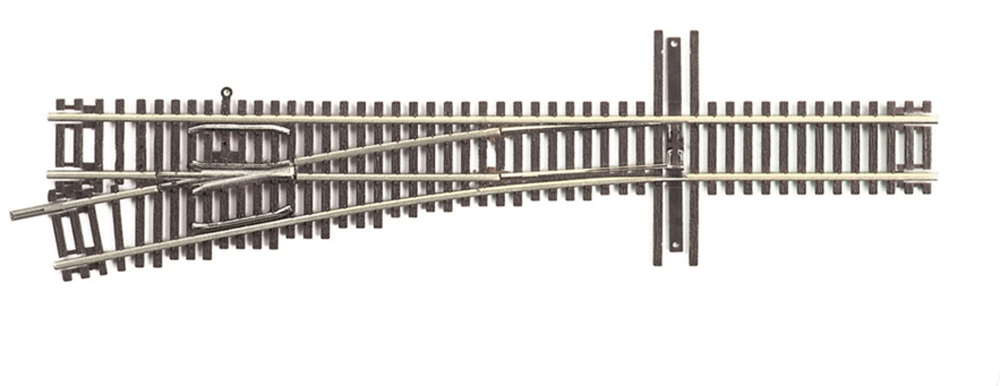

Atlas Model Railroad Co.

Atlas produces code 80 turnouts with insulated frogs in its Custom Line. No. 6, no. 8, wye, and continuous-radius turnouts are available.

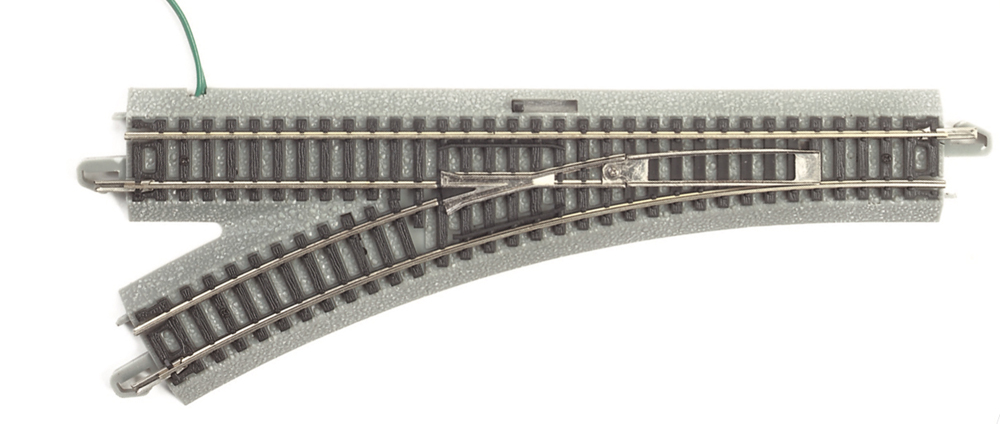

Bachmann Trains

Bachmann offers turnouts in its E-Z Track line. These turnouts feature code 80 rail and are molded into gray locking plastic roadbed. No. 4, No. 6, and No. 6 single crossover turnouts are available. All of the turnouts mentioned are remote.

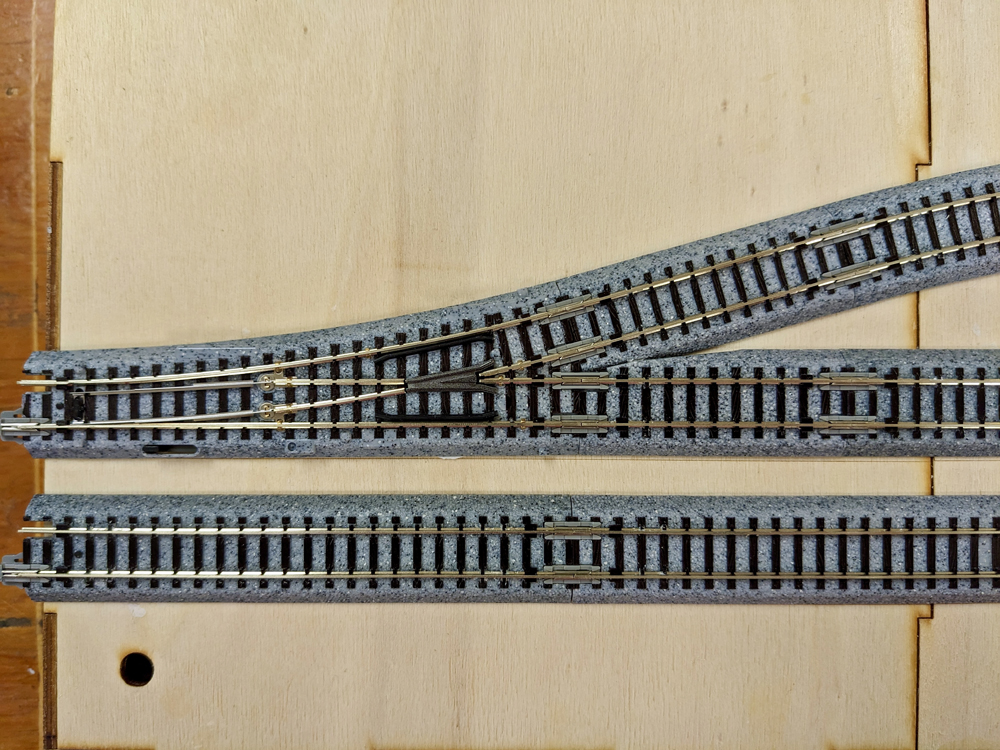

Kato USA

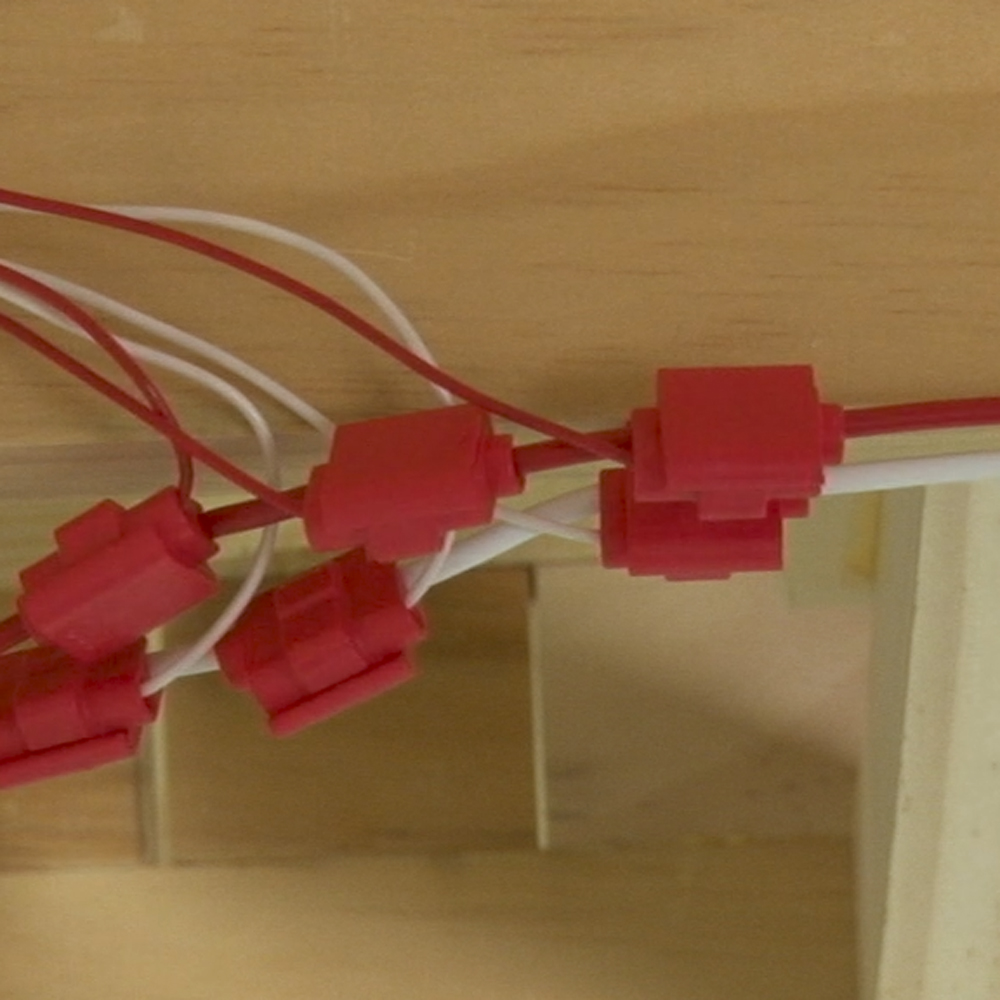

Kato’s Unitrack line offers a variety of turnouts. These turnouts are made with code 80 rail and are mounted on molded plastic roadbed. Pieces are connected with replaceable roadbed connectors. No. 4, No. 6, No. 2 wye, double crossover, and 6”-45 degree turnouts are available. The turnouts are controlled by concealed switch machines and can be remotely controlled.

Micro Engineering

Micro Engineering produces turnouts in code 55 and code 70. These No. 6 turnouts feature spring-lock switch points and molded plastic ties.

Peco

Peco offers turnouts in code 55 and code 80. All turnouts use the same frog angle and feature spring-lock switch points. Turnouts are available with insulated or all-metal-frog construction. More than 10 different standard and non-standard types of turnouts are available from Peco.

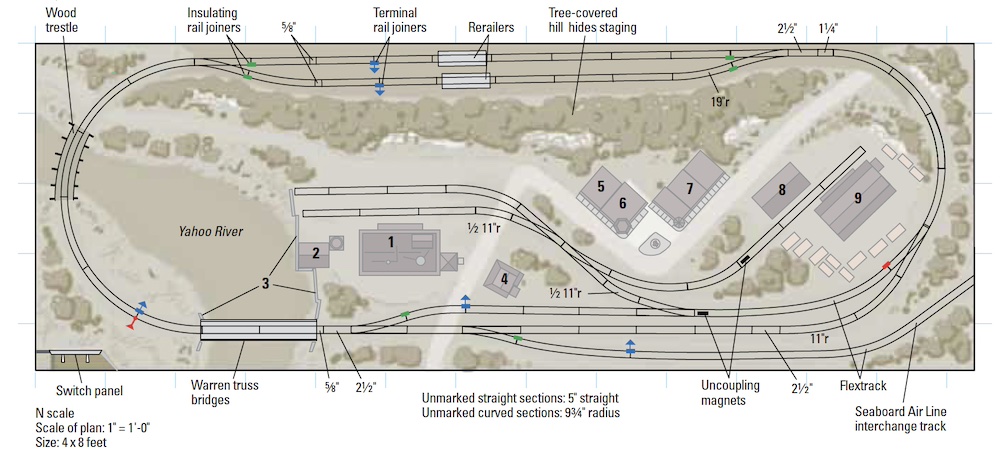

When placing turnouts with flex track always check your radius. Four, five, six, and seven are the maximum radius for turnouts.

If your track curves do not use a six and never use a number four. Number six turnouts you will kink your track if you install one of those and it could result in an s curve bow in your track on the curve. You are not installing a shoe fly right here you need to make sure that the radius in that area is correct. Number four turnouts are too sharp and they are only used in ladders. The correct turn out to use in a curve is a number five or a curved turnout. When placing a turnout near a curve make sure that you have it in a section that is straight do not place it in the middle of the curb and never try to match the radius of the curve to your turnout or you will get a kink and it will bind. Remember flex track acts like a spring if you try cutting a piece of flex track right in the middle and you try to put a turnout right there the spring is going to snap and the flex track will return back to what it was before it was laid and if you try hooking it up and soldering it the rails will compress into the curve and that spring action will shoot into the frog and into the stock rails on both sides causing a kink and if you bring a locomotive or cars through there they will bind, they will derail, and in some cases with expansion you will get what is known as a pull-up when that happens the track will bend on itself and it’ll be impossible for you to secure it to your layout because the caulking or super glue that you put in there it will pull up the road bad and the ballast and in some cases it will break the point rails and the frog. Cody explains the correct way to replace a turnout so this does not happen. When you put a turnout in any place you have a joint where there is flex track on a curve you need to cut those joints out and you also need to remove any places where there are springs because if you don’t the flex track will kick in on you and when you put that turnout in there it will not go back where it was a mistake that Cody and I learned the hard way. Also if you have any joints on curves leading into a turnout you must cut the curves because flex track will not go back where it was when it’s cut and the outside rail will bend outward and pull all the spikes out from the flex track which will result in you tearing out your layout to replace a section that is damaged. The order that you set these pieces in is first you measure where you’re going to cut and then you have to cut the rails on all three sides of the turnout. Once the rails are cut do not go with the radius of the curve always go one below it example if your curve radius is 60°, you need to use a number five if it is 50°, you use number four if none of those work and the radius is too sharp you have to tear out all your track and you have to install a curved turnout that way the track will not bind when you install things like a ladder or a siding on a curve.

Atlas also produces code 55 turnouts.

There are two other ranges of N scale track which are not mentioned:

1) Tomix. This is a Japanese prefabricated track system like Kato, but with a much wider range of turnouts than Kato. Also it has a more realistic ballast profile than Kato.

2) Fleischmann. This is a prefabricated track system which is a popular brand in Europe, and been marketed for many years.

There are two other ranges of N scale track which are not mentioned:

1) Tomix. This is a Japanese prefabricated track system like Kato, but with a much wider range of turnouts than Kato. Also it has a more realistic ballast profile than Kato.

2) Fleischmann. This is a prefabricated track system which is a popular brand in Europe, and been marketed for many years.