Digital Command Control (DCC) or direct current (DC)? That is the question. If you’re preparing to build a new model railroad or are just starting out in the hobby, you may be pondering the reasons to use DCC instead of an old-fashioned power pack to run your trains. Here are seven reasons to use DCC, and to be fair, one reason not to.

Simpler wiring

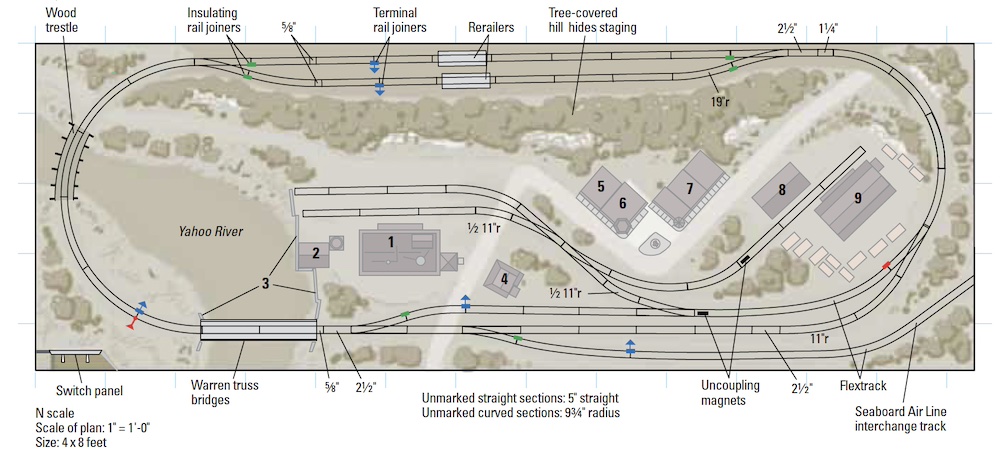

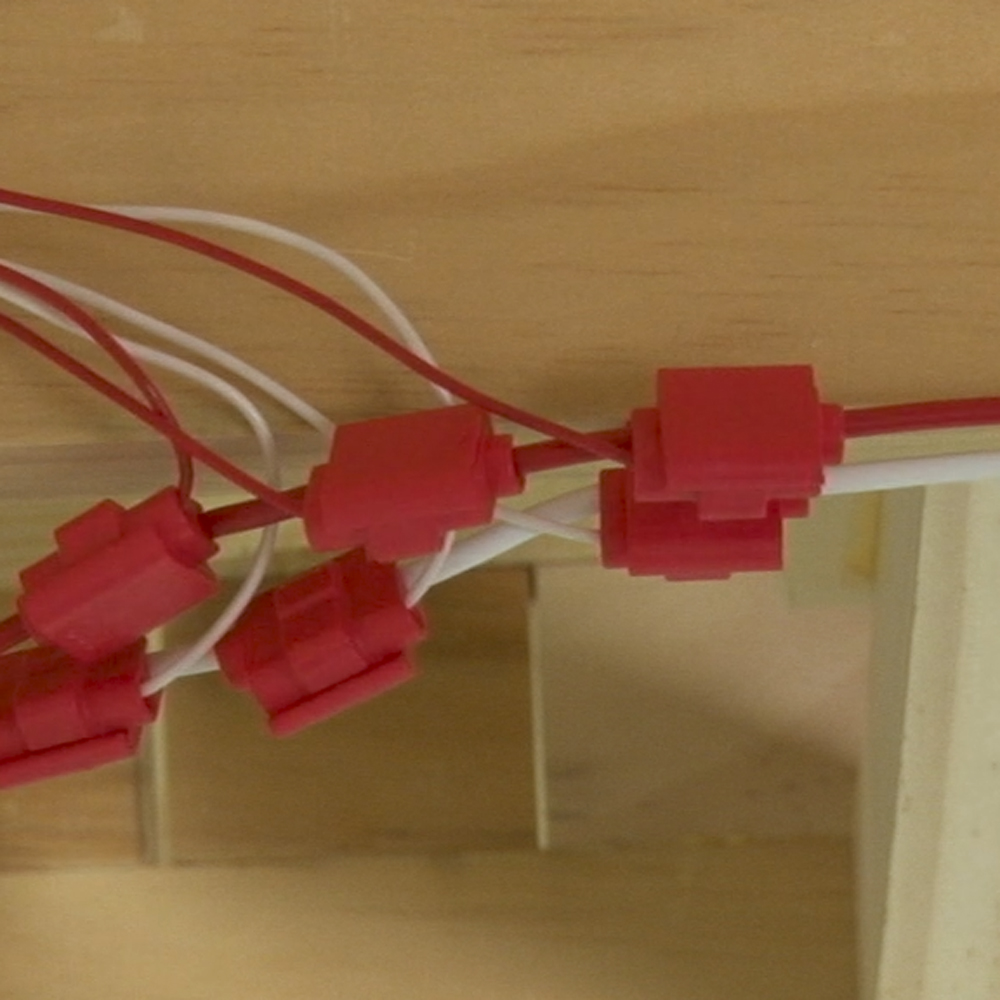

The first advantage DCC has over DC will become apparent before you even run your first train. Wiring a model train layout for DCC is much simpler than for DC block control. If you want multiple operators to be able to run multiple trains, a DC layout must be divided electrically into isolated sections called blocks. Each block is wired to a dual-pole, dual-throw (DPDT) switch that selects which power pack provides it with the voltage to run the trains. If it’s a large layout that can handle more than two trains at a time, more power packs are required, and wiring the power packs and control panels gets even more complicated.

Similar to the DC layout’s block is the DCC wiring district. But a DCC layout needs fewer wiring districts than a DC layout needs separate blocks, wiring one requires only one pair of wires (called the “bus”) from the DCC base station or power booster, and you don’t need a separate DCC base station for each one. In fact, there are only three reasons to create a separate wiring district in DCC: to add a power booster so the layout can host more trains running simultaneously; to isolate and eliminate short circuits; and to make a reversing section. If your layout is small enough to only have a few locomotives running at a time, you could get away with running the whole thing as one power district.

Speaking of reversing sections, powering those is also easier under DCC. Any loop, wye, turntable, or crossover that a locomotive can enter in one direction and leave facing the other way can be tricky to wire under DC. Reversing sections in DC require the engineer or dispatcher to flip a switch changing the polarity in a track block, which is both unrealistic and annoying. Digital Command Control devices called auto-reversers handle this, as you might guess from the name, automatically. You only have to handle lining the turnouts.

One track, multiple trains

One of the best known reasons to use DCC is that you’re controlling the locomotives directly, not the voltage on the track. This means you can run multiple locomotives independently on the same track. Yes, you can run multiple trains on a DC block control layout, but it’s not as easy. Only one train can operate in a block at a time. The operator has to know where on the layout the blocks begin or end so he can be sure to flip the switch assigning the next block to his throttle before entering it. If he fails to flip the switch, or if another engineer has a locomotive in that block already, there’s going to be trouble.

The advantage of DCC is obvious for a large layout that sees multiple operators running trains in realistic operating sessions. But what if you’re just a lone modeler, operating a small layout alone, one train at a time? It’s still easier to do things like setting up a meet at a passing track, sending a yard switcher to tack a caboose onto a departing freight, or simply pull one locomotive out of the ready track while others wait their turn. In DC world, such maneuvers would require making sure your locomotives are all in separate wiring blocks and flipping toggles to switch those blocks to different power packs. Not the most realistic operating experience.

Now, what if you want to run multiple locomotives together rather than separately?

Speed matching and consisting

It’s simple to double-head motive power or add a helper to the back of a train in DC – just couple on another locomotive and go. However, if the engines have different gearing or motors with different voltage requirements, they can fight each other. They might spin their wheels, create drag, or even cause derailments. But with DCC, you can adjust an engine’s “speed curve” – which governs how it responds to different throttle speed steps – by programming just three Configuration Variables (CVs). This is sufficient to make most locomotives play nicely with each other, but if you want even finer control, many decoders let you set each step of the speed table individually.

Setting up multiple locomotives to run as a unit – which in DCC is called consisting – is a little more complicated in DCC than just putting them on the same track. But the three consisting options available in most DCC systems let you choose which works best for you. Once you set up a consist, those locomotives will operate as one, seamlessly. And DCC is more realistic, too; in a DCC consist, only the lead unit responds to light and sound commands.

And speaking of lights and sounds…

Sound and lighting effects

These might seem like two different features, but they both boil down to one thing: making your locomotive do cool stuff with the push of a button. Being able to play different whistle signals, ring the bell, dim the lights, turn on Mars lights and warning beacons, activate the dynamic brake on a long downgrade – all these and more make you feel like you’re in the engineer’s seat more than ever before. And while optional sound effects like cab chatter and station platform announcements might seem frivolous, some are just fun.

Momentum and braking

This is another argument in the area of realistic operation. If you want your train to move realistically, you have to ease your DC throttle up and down gradually to avoid unrealistic jackrabbit starts and screeching stops. With a DCC decoder, you can program in acceleration and deceleration rates to realistically simulate how long it takes a loaded train to get up to track speed and come to a stop. Crank up the throttle on a momentum-equipped DCC engine, and it will slowly build up speed until it reaches the throttle setting. Likewise, spin the throttle down to zero, and it will slow gradually, just like the real thing. A model engineer will have to take his train’s momentum and braking distance into account, just as an engineer on the prototype must. And if the model is equipped with a sound decoder, you might even hear the brake pads squealing on the steel wheels. Now that’s cool!

Stationary decoders

Modelers considering switching to DCC might not think about it, but DCC can control more than trains. Stationary decoders, which go on the layout rather than in rolling stock, can control structure lights, industrial sound effects, animated crossing gates, and the like. Stationary decoders can also control turnout motors, lining the points of a single turnout or an entire route through a yard ladder at the touch of a throttle button.

Wi-Fi and computer control

Digital Command Control decoders are at heart tiny computer processors. They receive and respond to commands from other computers in our DCC base stations. But they can interface with other computers, too, such as the one in your pocket. System accessories like MRC’s Prodigy WiFi, the Digitrax LNWI LocoNet module, and the NCE WFD-30 connect your DCC network to WiFi. Your operators can then control their trains with a free smartphone app like WiThrottle (for Apple iPhones) or Engine Driver (for Android devices). Never run out of throttles again!

You can control a DCC layout with a laptop or desktop computer, as well. Java Model Railroad Interface, or JMRI (jmri.org), is a suite of free, open-source software for DCC. Applications make it point-and-click easy to perform tasks like programming your decoders, controlling signals and turnouts, and creating operations paperwork like train manifests and switch lists. And since it’s written in Java, it can run on almost any computer operating system.

One reason not to use DCC

There is one large drawback that might make a modeler think twice before deciding to make the leap to DCC – the price. Model locomotives equipped with decoders can cost from $50 to $120 more than the same engine with DC power, depending on the locomotive’s scale and the features of the decoder. If you already have a large fleet of DC locomotives, upgrading them to DCC would be a substantial investment (and that’s assuming your old locomotives can be upgraded). The cost of a DCC base station, power boosters, circuit breaker modules, auto-reversers, and extra throttles can mount up. Whether the advantage of the seven reasons to use DCC that I’ve listed above outweigh those costs is up to you.

If you’ve been convinced to use DCC on your next layout, get more information from a book like The DCC Guide, Second Edition; Basic DCC Wiring for Your Model Railroad; or DCC Projects & Applications Vol. 4, all of which are available in the Kalmbach Hobby Store.