Whether you’re just beginning in the hobby or you’ve been at it for 50 years, almost every model railroader comes across this question: should you use flextrack or sectional track when building your layout?

I’ve used both throughout my time in the hobby, and in multiple scales. My first suggestion would be to use both. Grab a few pieces of both flextrack and sectional track and figure out what style suits you best. It’s like the difference between being a visual learner or an auditory learner.

Let’s look at some of the positive attributes of each style to find the best option that works for you. Who knows, maybe you’ll end up using a mix of both!

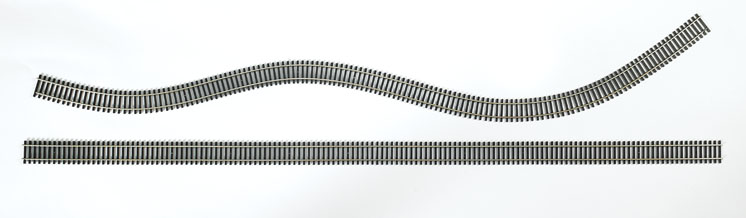

Flextrack gives you (virtually) infinite possibilities. This is perhaps the number one reason that modelers go with flextrack — it flexes to almost any shape that you desire. With Flextrack, you are able to make curves that you just can’t make with sectional track. With each piece being 36” long, you can make long runs or cut a piece to be as short as you need.

If you’re building a module, or modular layout, sectional track is perfect for keeping lengths to a module system’s standards. For example, T-Trak standards give the needed pieces per straight or curved module so that each module has the right spacing between them for connecting and disconnecting. The Kato Unitrack joints are actually the only method that keeps those modules connected.

Flextrack improves your layout’s realism. Now, you can make a realistic layout utilizing sectional track, but flextrack will improve that realism. Sectional track is typically only found in code 100 and code 83 in HO scale and code 55 in N scale, whereas flextrack can be readily available all the way down to code 55 in HO scale and code 40 in N scale. This allows for realistic code variations between main line track and sidings or spurs. In addition, some companies produce flextrack with more realistic tie size and spacing than sectional track. And you won’t have to worry about joints every 9” (we’ll get to that later on).

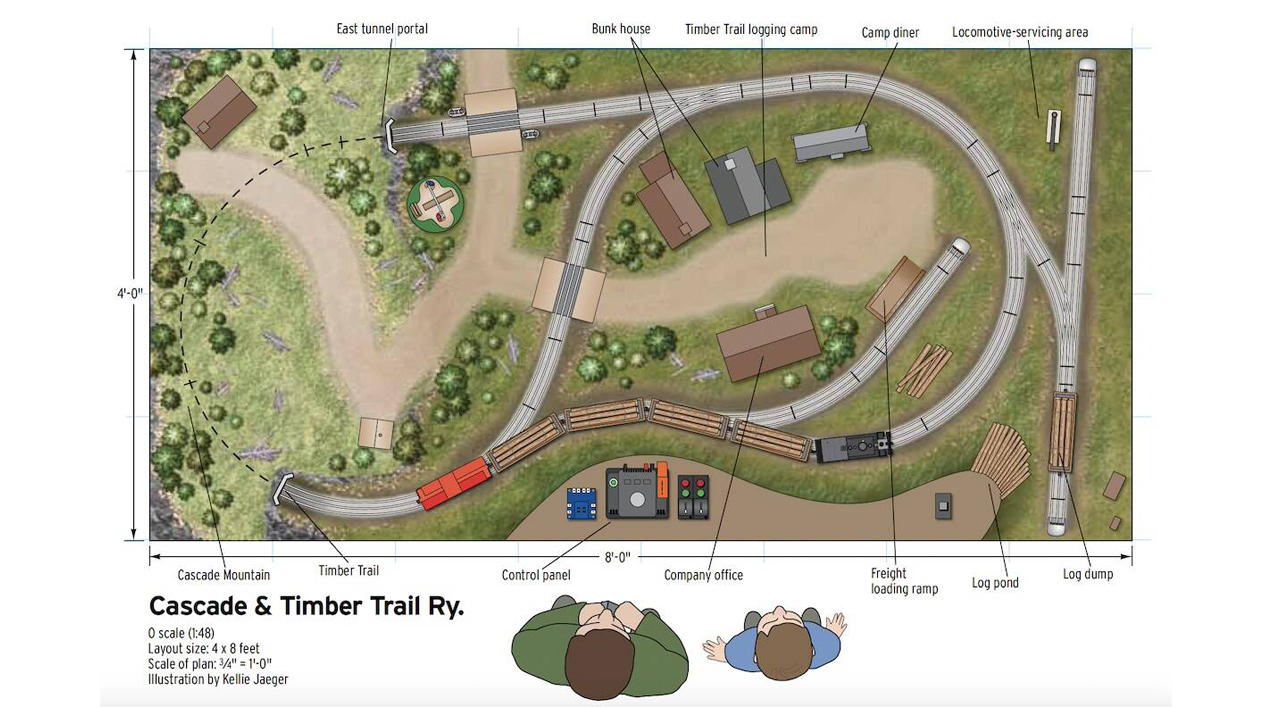

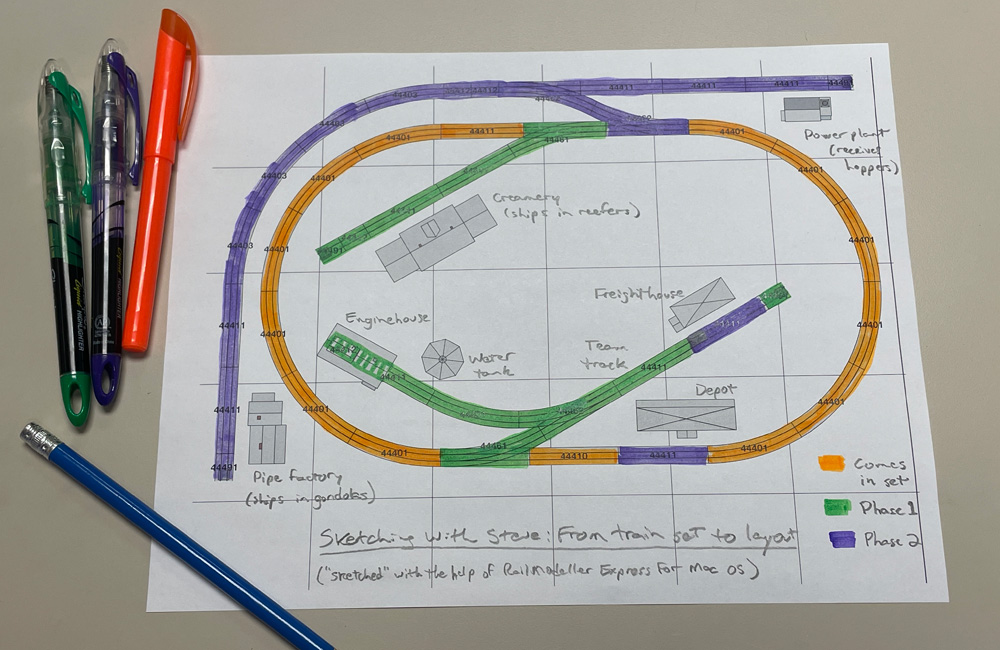

Sectional track is great for following track plans. If you’re following a track plan in a book such as Starter Track Plans for Model Railroaders, chances are good that the track plan involves sectional track. Many basic plans have been designed so that the track can be put together quickly, and thus allowing trains to be run as soon as possible. While these plans could also be built using flextrack, it might be a better idea to find a more advanced plan that is a better suited for flextrack.

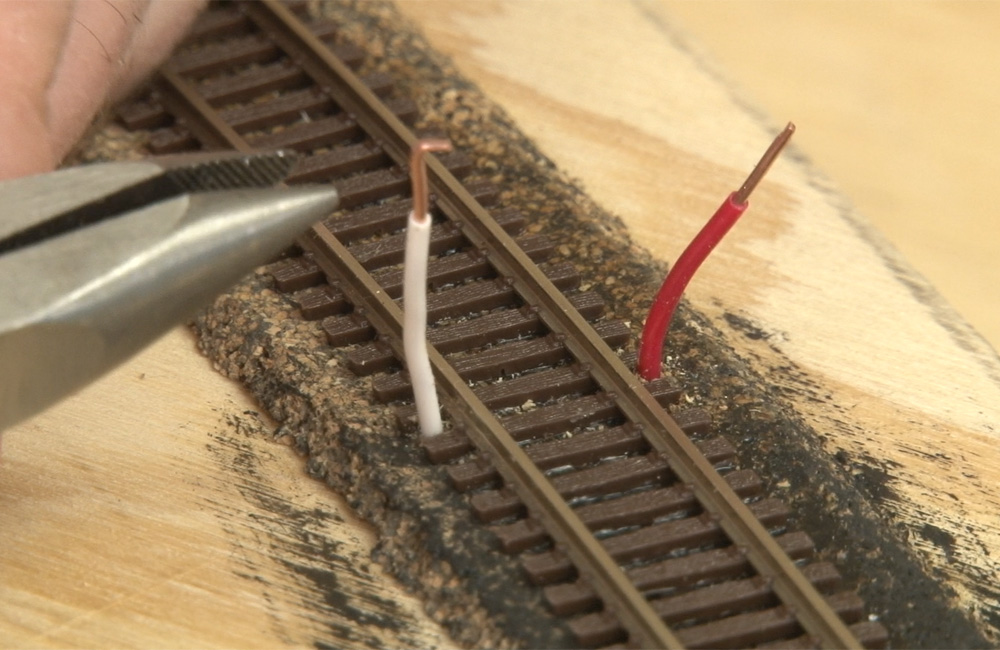

Flextrack provides for more reliable electrical connectivity. As I mentioned earlier, sectional track lengths are typically only 9”. It’s recommended that feeders from the track to your bus be dropped every 3 to 6 feet. If you’re using sectional track there is no going around this. With joints every 9” or less, power loss is increased the further you get above 6 feet.

Sectional track is ideal for experimenting. If you just bought a 4 x 8 sheet of plywood and laid it on some sawhorses, or you just want to see what you can build on your kitchen table, sectional track is the way to go. The track will keep its shape and sectional track with roadbed will hold everything together short of some strength to take it apart again. Some flextrack will hold its shape for planning out a layout, but in order to run trains you’re going to have to secure it with some other means.