I enjoy scratchbuilding structures from styrene because it’s easy to cut, it takes glue well, and it’s readily available, 1. Though cutting wall sections is easy, making door and window openings can be tedious. However, with the Nibbler cutting tool, you can cut openings quickly and accurately. The Nibbler is a hand-operated punch-and-die tool that cuts 3/32″ bits out of styrene up to 1/16″ thick (or thinner sheet metal). It’s available from Micro-Mark (micromark.com) and electronics supply houses.

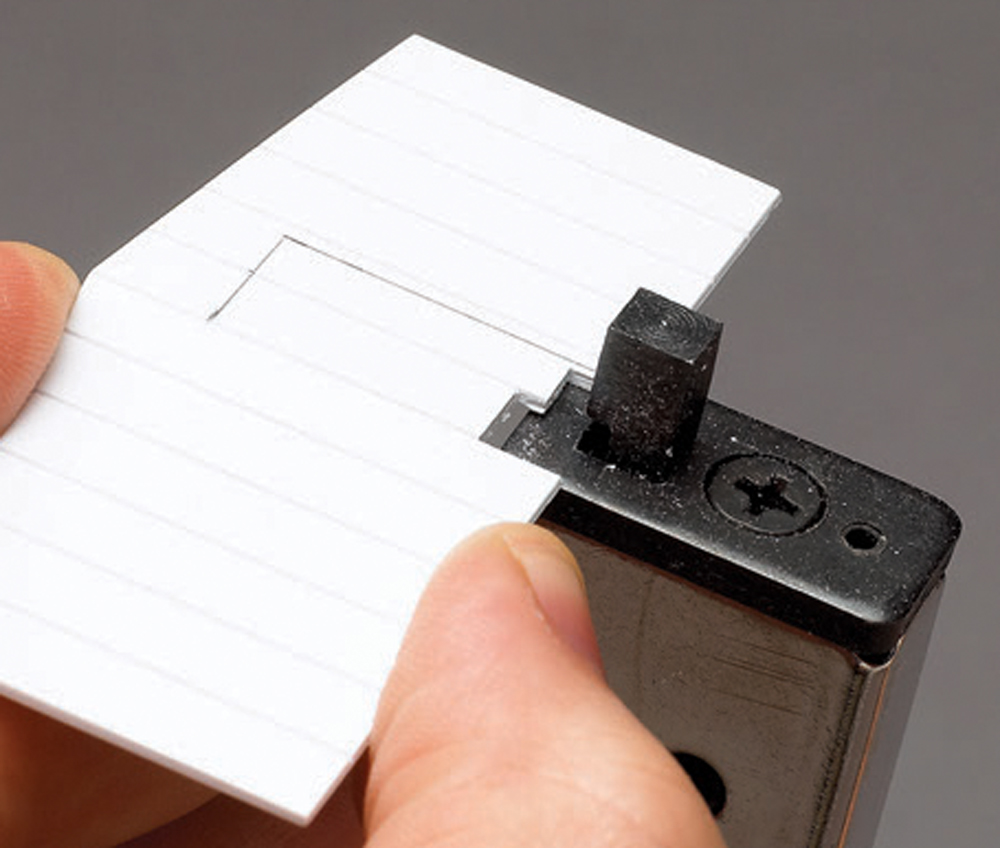

For doors, I first outline the opening with a pencil. Then I use the Nibbler to cut away the styrene, 2, test-fitting the door frequently to make sure I don’t cut away too much material.

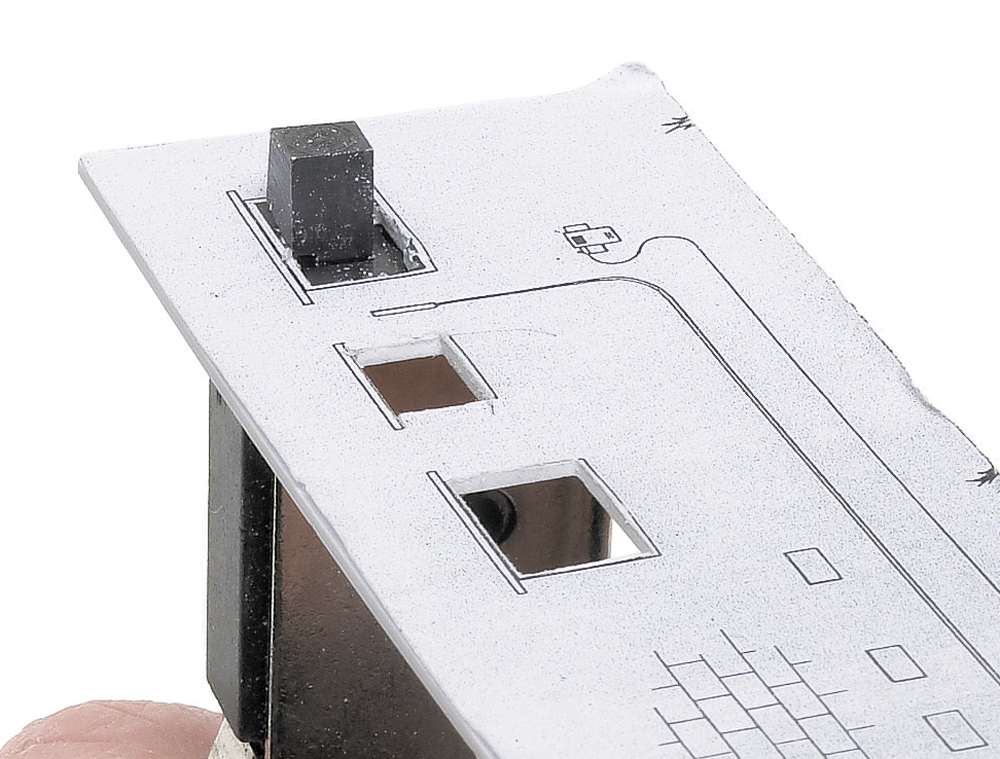

Windows and doors in the center of the styrene require a slightly different approach. Once I have the window locations marked, I use a 15/64″ bit to drill an opening in the center for the Nibbler’s cutting head, 3. Then I use the Nibbler to cut the styrene, 4.

Don’t cut all the way to the pencil lines for the openings. Instead, leave a bit of material and use sanding sticks and jeweler’s files to finish, 5.

If you plan on doing a lot of scratchbuilding with styrene, give the Nibbler a try. You’ll be happy with the results.

1. I used the Nibbler, a hand-operated cutting tool, to make door and window openings in the office for this LP plant. The Nibbler can be used on styrene up to 1⁄16″ thick (or thinner sheet metal).

2. If a door goes to the bottom of a wall, mark the opening with a pencil and use the Nibbler to take bites out of the styrene.

3. If windows or doors are in the center, drill a hole in the middle of each opening to make room for the Nibbler’s cutting head.

4. Once the hole has been drilled, use the Nibbler to cut away the rest of the styrene, but don’t cut all the way to the pencil lines.

5. Use sanding sticks and jeweler’s files to smooth the edges of the openings.

A trick I’ve used is a fine saw blade in an X-acto knife.