Learn how to weather the model train cars like their hard-working prototypes

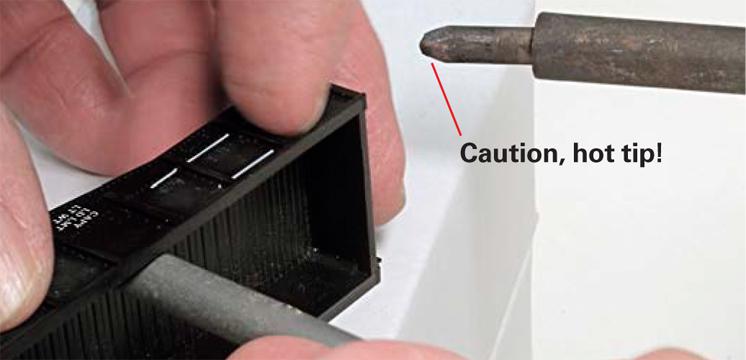

It’s relatively easy to simulate normal wear and tear on a plastic model of a steel gondola. I begin by clamping a medium-wattage soldering iron horizontally in a metal-jawed vise. Before plugging in the iron, I position a couple of blocks of 2 x 4 to support the gondola body on its side just above the hot iron. This keeps the hot tip from touching the side or floor, although an occasional nick in either surface adds to the realism. Just be careful to avoid damaging any safety appliances.

When the iron is hot, I slip the carbody into position so the heat softens a side panel between two of the exterior posts. I try to err on the safe side, as I don’t want the plastic panel to sag. I then slide the gondola body clear of the hot tip and use the round handle of a small hobby knife to push out on the softened panel from inside. Then I repeat the heating and pressing sequence as needed.

The resulting bulged panels may distort the car’s factory lettering, so I go easy with reshaping the body near any printed panels. For repainted cars, I add the wear-and-tear effects to the carbody before I apply its decal or dry transfer lettering.

I spray the interior of most gondolas with a rust-colored paint or use weathering powder; I use grimy black to weather gondolas painted boxcar red. Last, I scatter some debris on the floor and secure it with a heavy spray of Testor’s Dullcote.

This weekend is a local (Milwaukee area) train show where one vendor sells boxes full of train-set quality freight cars, often with busted trucks or couplers, for a buck or two each. I'm going to buy a few Tyco or Varney/Life-Like gons and give Tony's ideas a try before risking them on some of my nice Walthers, Proto 2000, or Bowser gons. The problem is, if I do a really nice job on a junker car I'll be tempted to put it on the layout!

When using a heat source to soften styrene plastic it is helpful to have a spray bottle with cold water to mist the plastic if things seem to be going too far.

I have photos of gondolas (in active service) where the top beam or angle is not only badly dented, but partly gone, and also where side panels (and floors) have actual holes in them. I have even seen and photographed a few where the grab irons and ladders have taken a beating, although the FRA would likely not approve the use of a car with damaged safety appliances. Metal takes a beating that is very difficult to replicate in cast plastic. Even Tony's methods do not precisely replicate some forms of damage.

I just did a gondola using a propane touch set to the lowest flame to distort the sides and top edges.

You have to be careful that the styrene doesn't catch fire while you move the flame.

I just used the edge of the bench and pushed gently while the plastic is hot.

I found that it gave me realistic distortion just like to might expect if a crane with an electromagnet was banging top and sides while manuevering a load of scrap.

Very nice.

Here in Spain is the same !poor gondolas!

I know its politically incorrect in today's society but its easier, and safer to use a cigarette. It weighs less and your hand is pointing away from the heat.

Nice article, but I haven't seen many gondolas with the top of the angle iron bent as shown in the first photo. I have seen many photos that show the sheet metal sides are bulged outward between the ribs but not the top angle iron.

Some modelers have done some amazing weathering and wear/tear to their gondolas. I just haven't mustered the courage, but I will try it on one sometime.

Tried this on a few gons that I weathered for a friend. This technique works very nicely but you do have to be careful not to overdo it; particularly, as Tony suggests, where lettering or a logo appears.

Extra "rust" on the inside of bulges helps, too. That's where something heavy shifted or was dropped during loading; besides bulging the panel, that removed a lot of paint so the steel rusted.

I am going to have to try this method.

Great article. Looks like a fun easy project that can add realism and boost confidence to move on to other rolling stock projects for the beginner or a good evening or two project for others looking for a fun quick project during a busy summer.