Electrical problems in turnouts and switches and how to fix them

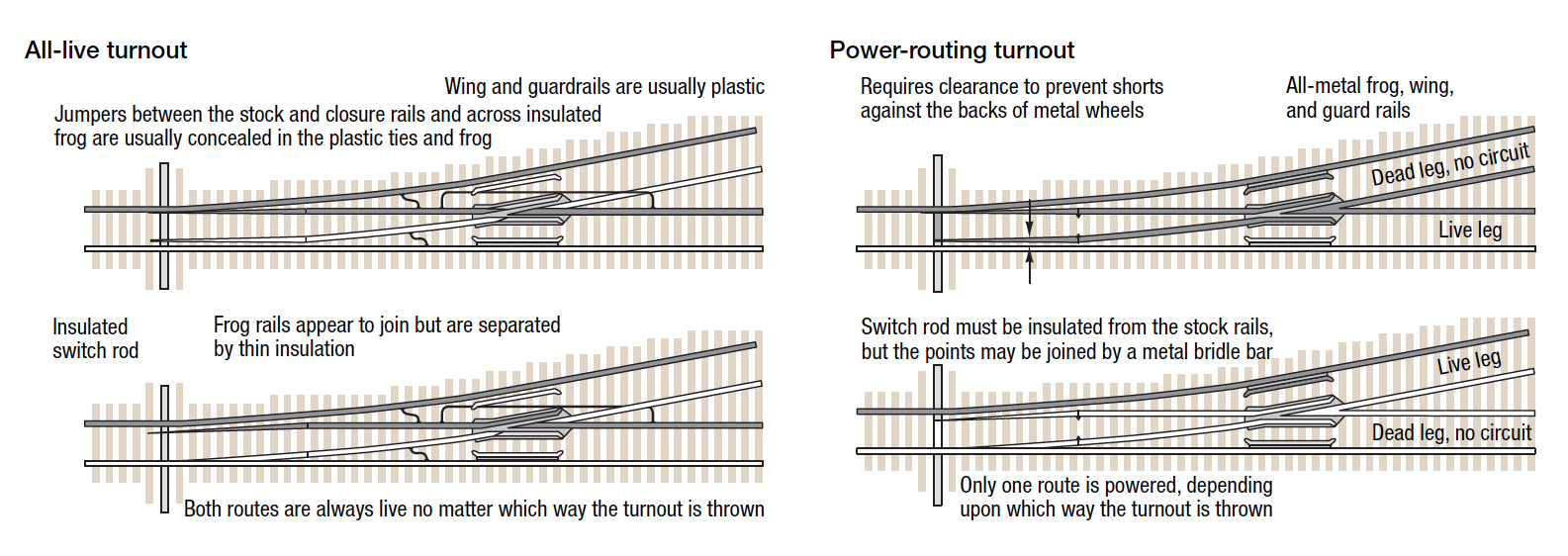

Turnouts are either all-live or power-routing. Each type has its own set of electrical characteristics to consider. The illustration above shows the basic differences between all-live and power-routing turnouts.

An all-live turnout has a solid plastic or isolated metal frog that keeps rails of opposite polarity insulated from one another. These turnouts have jumper connections around the frog and between closure rails and their adjacent frog rails or stock rails.

A power-routing turnout is all metal rail with no insulation at the frog and no jumper connections. This type of turnout can power only one leg at a time. Power is routed when the point rail makes contact with a stock rail, sending current through the metal frog.

Each type of turnout requires different wiring techniques. Generally, all-live turnouts are easier to wire, using feeders as with any track section. Power-routing turnouts require that rails be insulated at certain points by cutting gaps in the rail or using plastic rail joiners, especially when turnouts are oriented frog to frog, to avoid short circuits.

If your test train stalls on an all-live turnout, make sure that the problem isn’t with your locomotive. Some modelers choose not to use all-live turnouts because the insulated frog is a dead spot where locomotives with short wheelbases or limited power pickup can stall at slow speeds. This has become less of a problem since most new diesel locomotive models, as well as many current-production steamers, pick up power from all their wheels.

If a second locomotive stalls on the same turnout, check the voltage of each route with a multimeter. The readings should all be the same, regardless of the position of the points. If one route isn’t receiving power, then one of the factory-installed jumpers could be broken. You can fix this problem without having to install a new turnout.

First verify the location of the break, using a jumper wire with an alligator clip attached to each end. Attach the clips to the corresponding rails around the frog. The dead route should now receive power. Once you’ve established where the break is, you can install a permanent jumper.

If your locomotive stalls through the frog of an all-live turnout, the problem could be a short circuit. The diverging rails leaving the insulated frog may be close enough for a metal wheel to bridge the gap and cause a short. To fix this problem you’ll need to insulate the rails where they leave the frog by coating the tops of the rails with epoxy.

If your test train stalls on a power-routing turnout, the point rail may not be making contact with the stock rail. You can verify this with a multimeter by checking the continuity or current path through the powered turnout route. First set the meter to read resistance (ohms), then touch one lead to the stock rail contacting the point and the other lead to the frog.

A reading of zero indicates a strong current path, while a higher reading indicates a weak current path.

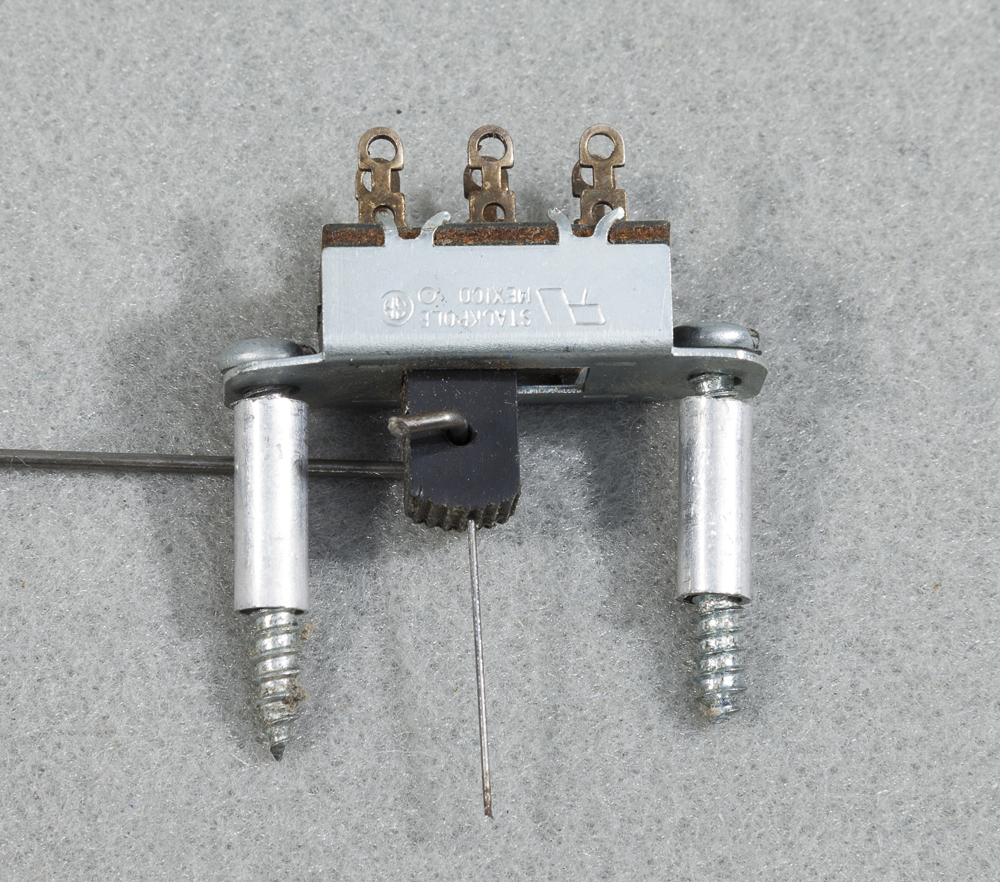

Some power-routing turnouts have thin metal tab contacts attached to the points that make contact by sliding under the stock rail. These tabs tend to weaken and bend down over time. Although the tabs are hard to reach, you can use a thin screwdriver to bend them up and then apply contact cleaner to them.