Model a weather-beaten wood structure: In model railroading, weathering is typically associated with freight cars and locomotives. However, structure weathering is another way to add realism to a layout. Peeling and faded paint, a roof in need of repair, and broken glass are just a few of the ways to turn an ordinary structure into a standout model.

For this project, I used an American Model Builders HO scale Northern Pacific class C depot kit. Though I’ve built structures in plastic, brass, and plaster, I prefer wood for detailed weathering projects like this.

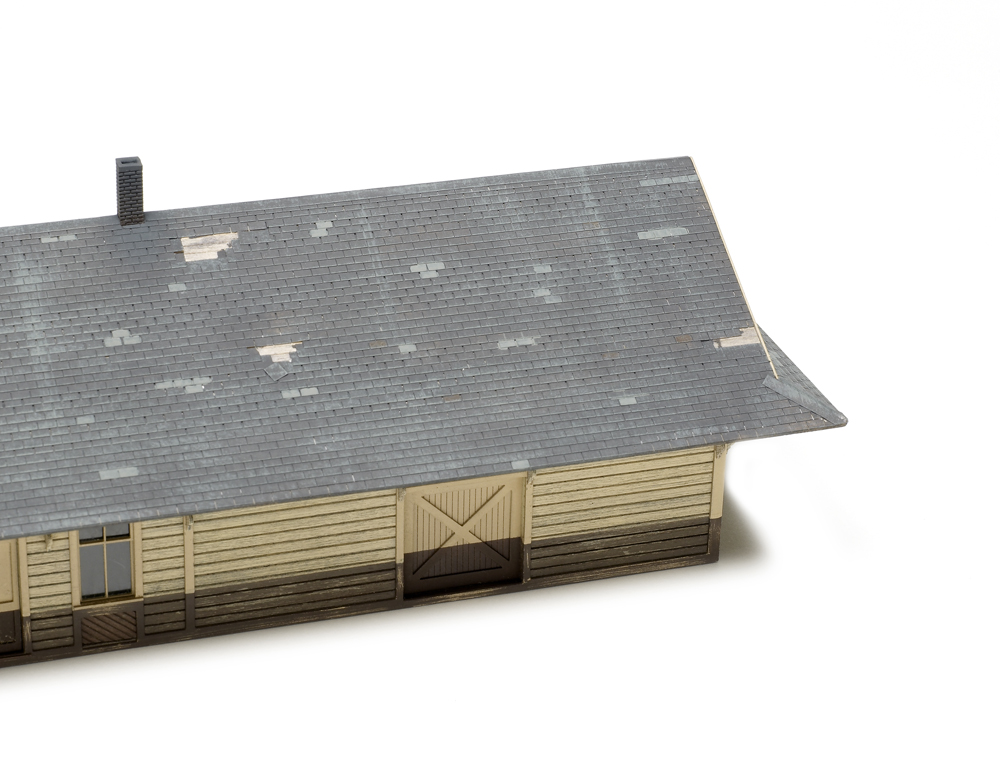

Structure weathering doesn’t have to be limited to just the walls. On many layouts, the roof is the most visible part of a building. Vents, air conditioners, and antennas, among other things, can make the roof visually interesting. Though I didn’t need those details here, I enhanced the depot roof by leaving shingles off this abandoned structure, exposing the bare subroof. I also painted individual shingles to look like patchwork repairs had been made over the years.

You’ll be surprised by how easy it is to turn an ordinary wood kit into one that will get the attention of visitors and members of your operating crew. Give these techniques a try. You’ll like the results.

Step one: Stains

It’s easy to give wood that gray, aged look with stains. Timberline Scenery Co., A-Line, Micro-Mark, and Hunterline, among others, offer factory-mixed stains in a variety of colors. You can use the stains individually or in combination to create different effects.

Another option is to mix your own stains with India ink (available at most art supply and craft stores) or acrylic paint and 70 percent isopropyl alcohol. My favorite mix is two teaspoons of India ink to one pint of isopropyl alcohol. You can make the stain lighter or darker by adjusting the amount of ink. For a warm-tone stain, substitute sepia ink for India ink.

Step two: Applying the stain

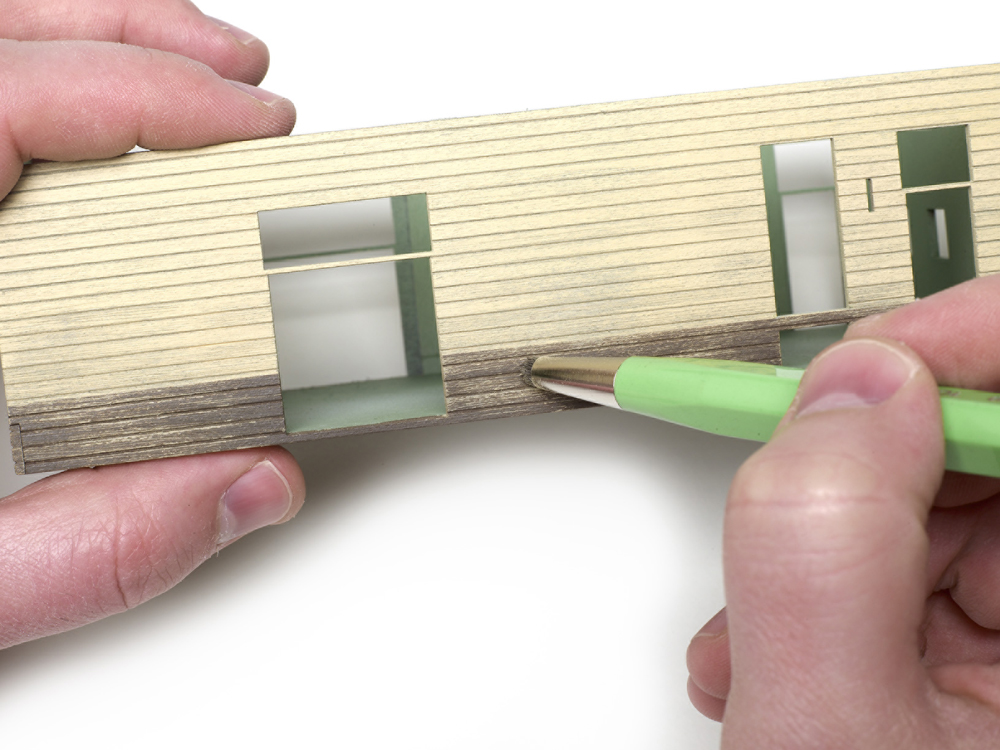

I stained the walls of the NP depot with the India ink wash described in step 1. I applied the wash with a 1⁄2″ paintbrush, brushing with the wood grain. I used all of the stain on the brush before reloading it. As you can see on the basswood wall section in the background, this technique yields a variety of light, medium, and dark gray planks.

The photo also illustrates how different types of wood take stain. The basswood wall in the background required only one application of stain. I had to apply two coats of stain to the microplywood roof brackets for the same look.

Since 70 percent isopropyl alcohol contains 30 percent water, the India ink wash may warp the wood parts. To prevent this, I laid the wet parts on a flat surface, covered them with paper towels, and laid heavy books on top of them. I let the stain dry for 48 hours.

Step three: Bracing

The depot walls have a milled siding pattern that’s flexible across the grain. To prevent the walls from warping or sagging over time, I braced them from the inside using assorted pieces of stripwood. Then I masked the exterior walls and sprayed the interior with Rust-Oleum Gray Automobile Primer. Once the primer dried, I painted the interior walls with Model Master Pale Green.

Step four: Distresser and finishing pad weathering

Next, I masked the interior and sprayed the exterior with Polly Scale Sand and NP Dark Brown (three parts Roof Brown, one part Boxcar Red). I let the paint dry for 24 hours and then used Micro-Mark’s Distresser weathering brush to scrape off the paint and expose the stained wood. In the top photo, you can see the bristles are exposed about 3 ⁄16″, which is ideal for heavy weathering. If you prefer a lighter touch, expose more of the abrasive bristles.

I used a 3M wood finishing pad (no. 07415) to remove fuzz created by the Distresser brush. In the process, I discovered that the pad works well for weathering, too. I used it to lightly remove the sand and brown paint, as shown in the bottom photo. I also used the pad to weather the delicate peel-and- stick cardstock trim.

Before weathering the building, I applied blue painter’s tape where the station sign would have been.

After I finished using the Distresser brush and wood finishing pad, I applied a final wash of India ink. This stained any bare wood exposed by the Distresser brush and further muted the paint. Once the wash dried, I attached the trim. Don’t apply an alcohol-based wash after the peel-and-stick trim has been attached to the model, as this may cause the adhesive to come off.

Step five: Roof weathering

I weathered the roof fairly heavily to further reinforce that the depot is abandoned. I started by applying the peel-and-stick three-tab shingles, omitting random patches to reveal the bare sub-roof. Next, I brush-painted the shingles Polly Scale Union Pacific Dark Gray. I highlighted individual shingles by painting them with the same firm’s Roof Brown and Louisville & Nashville Gray. I then used a Microbrush to apply Hunterline Light Gray wood stain to the subroof. I applied the alcohol- based stain sparingly so it wouldn’t attack the shingles’ adhesive backing.

I highlighted the shingles by drybrushing them with L&N Gray. I dipped the brush into the paint, wiped off all but a trace amount on a paper towel, and lightly dragged the brush over the shingles in a horizontal motion. The idea is to highlight raised edges and details. I finished the roof weathering by using an airbrush to add soot stains to the chimney and nearby shingles.

Step six: Broken glass

I modeled the broken glass in the operator’s bay using the kit’s clear styrene. First, I marked the locations of the four panes. Next, I cut all but a corner out of the lower right pane. I simulated the shatter marks with a no. 11 blade.

To suggest the windows are dirty, I used a Microbrush to apply Polly Scale Clear Flat on the opposite side of the styrene from the scribe marks. I prefer the Clear Flat over aerosol Testor’s Dullcote, as the latter gives the clear glazing a frosted look. My goal was to simulate dirt and grime while keeping the windows somewhat transparent.

For more information on structure weathering, read Model Railroader senior editor Cody Grivno’s Weathering structures with drybrushing.