For my money there’s nothing much less exciting than a string of empty piggyback flatcars passing by, and nothing much more interesting than a string of loaded ones. We N scalers have had this type of long flatcar available since the late-1960s, but Micro-Trains jacked the realism bar when the firm introduced its model of an American Car & Foundry 89-foot car in the early 1980s. [BLMA has a well-detailed car based on the 1966-68 ACF “F89-J” class built for Trailer Train. – Ed.] Introduced in 1962, the prototype dominated the field.

It was several years before I finally had enough of a layout to run the cars, and the results were very disappointing. I just couldn’t keep them on the track. There’s almost always one big problem with flatcar models. They don’t weigh enough, even if the bodies are cast entirely in metal. These M-T cars have cast-metal frames with plastic decks. Nor is there any place to add enough weight to make much of a difference.

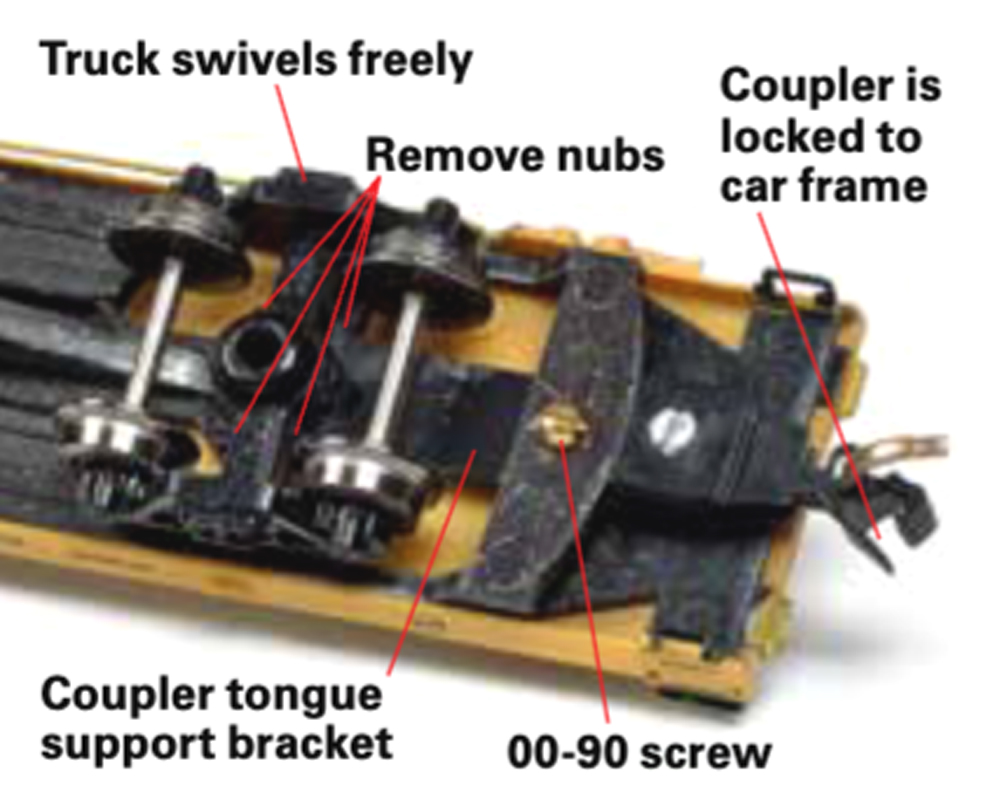

To do this I disassemble the car and clip off the little tabs on the tongue that force it to pivot in the direction the car is turning. Then I fasten the tongue to the support bracket with an 00-90 screw.

These body-mounted couplers made for a considerable improvement, but the cars were still prone to derailments.

The problem remained lack of weight, so I decided to weight the trailers and keep them on the cars permanently. I tried some stick-on lead weights by A-Line and got considerable improvement, although they made the trailers top-heavy, and when they fell over they went with a vengeance.

The decks of these cars were usually sprayed with an off-white anti-slip coating. The white surface was also a visibility aid to crane operators loading the cars, although much of the time the decks were so filthy with grime and grease from the trailers that it was difficult to tell what color they might be.

If you have the option of modeling the landing gear wheels up or down (with Train Worx trailers you do), generally you want them up on a loaded trailer, with the fifth-wheel bearing all the weight.

I have a rudimentary intermodal track at the Bakersfield yard, but most of my TOFC traffic is run-through. The few TOFC cars we do handle are loaded and unloaded circus-style. That is to say, empty cars serve as a bridge to reach the nearest trailer and roll it off.

Woe be to the guy somewhere up the line who loaded a trailer backwards so that it can’t be unloaded. A switch crew has to take the car over to the turntable, reverse it, and bring it back, which isa fun operation to perform.

During my time period the Santa Fe used a retired flatcar as a piggyback ramp at its Bakersfield yard. The price was right, and if it got hit too hard it would just be shoved down the track a ways, and a forklift would be brought in to pull it back into position. My article on this was in the October 1984 issue of Model Railroader.

Here’s hoping something here helps you get those pigs on the move.

This column originally appeared in the March 2015 issue of Model Railroader – Ed.

Can you tell me the approximate weight of the lead strips you put in each trailer. I live in New Zealand and don't have easy access to A-Line products. But I have alternatives if I know the weight you used. Thank you.

You must have the luxury of enough room for wide radious curves.