Many modelers build their layouts with commercial turnouts with the expectation that these components are ready to install. However, building my HO Ohio Southern has convinced me that most commercial turnouts are really “ready to finish.” They may need a little tune-up to ensure smooth performance and reliable operation.

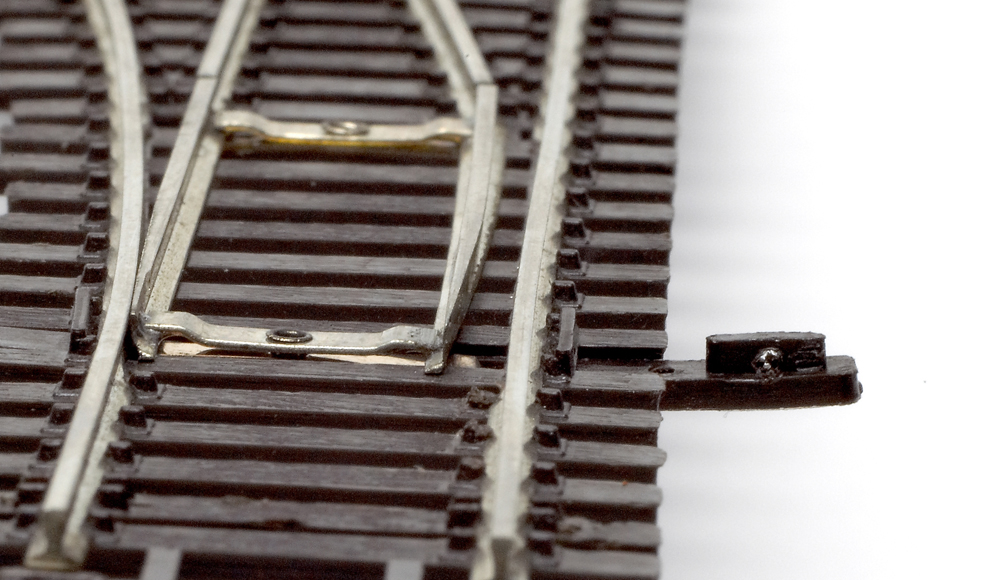

Gauge (the proper spacing of the rails) is critical throughout, and anything that impedes the smooth passage of the wheels is a potential problem. I use a National Model Railroad Association standards gauge to check these items on my turnouts, 1.

Where the track gauge is too tight, it squeezes the flanges between the railheads, forcing the wheels to climb up and derail. If the gauge is too wide, the wheelsets can’t span the extra distance between the guardrails and the frog, which forces the wheels to bounce up and again leads to derailment.

Most of the turnouts I’ve used tend to be a bit wide at the frog. I correct this by using a needle file to remove material from the inside faces of the guardrail and the frog until the gauge pins fit properly. I sharpen the point of the frog at this time as well.

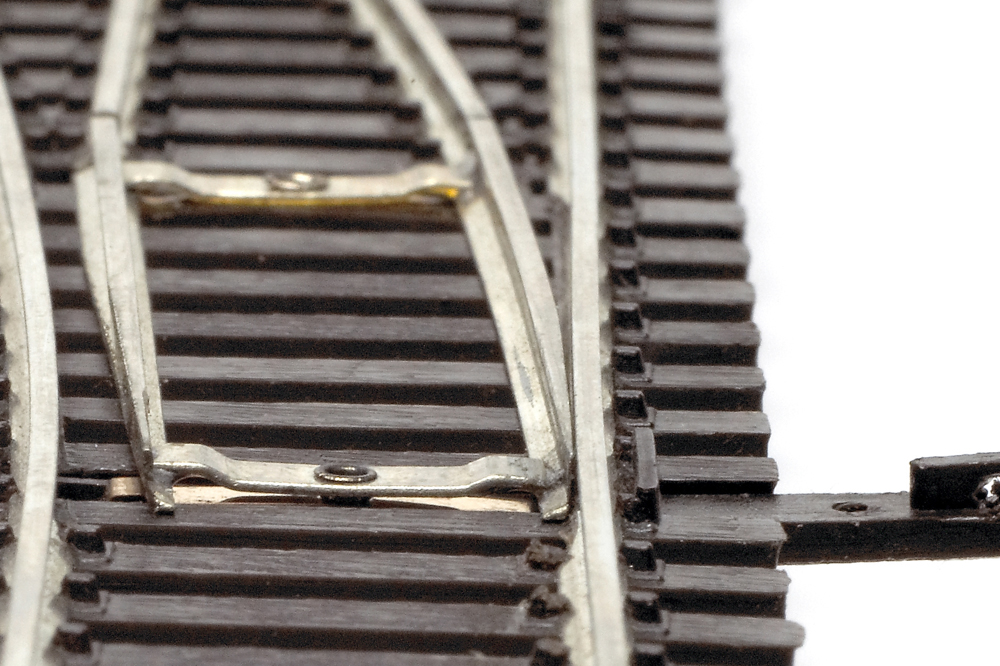

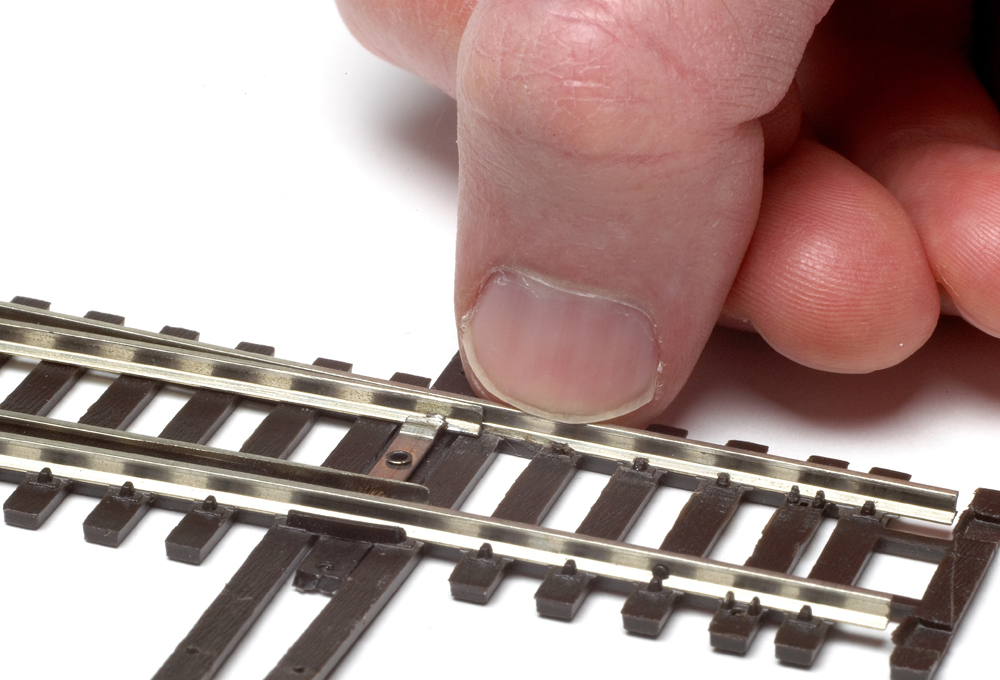

I use a flat needle file to sharpen the movable switch points. Manufactured points tend to have blunt ends that can catch wheel flanges, 2, so I file each point to a gentle taper that fits tightly against the stock rail, 3. To provide a smooth passage for the wheels, I also taper the top edge of the point. If you can slide a fingernail over this transition without it snagging, the wheels will also pass the point easily, 4.

These steps take only a few minutes, but they pay off big time with problem-free operation, which makes running trains that much more fun.

1. Use a National Model Railroad Association standards gauge to check turnouts and make any necessary adjustments before installing them on your layout.

2. Some commercial turnouts have blunt points that can catch wheel flanges and cause derailments.

3. File the blunt points so they fit flush against the stock rail.

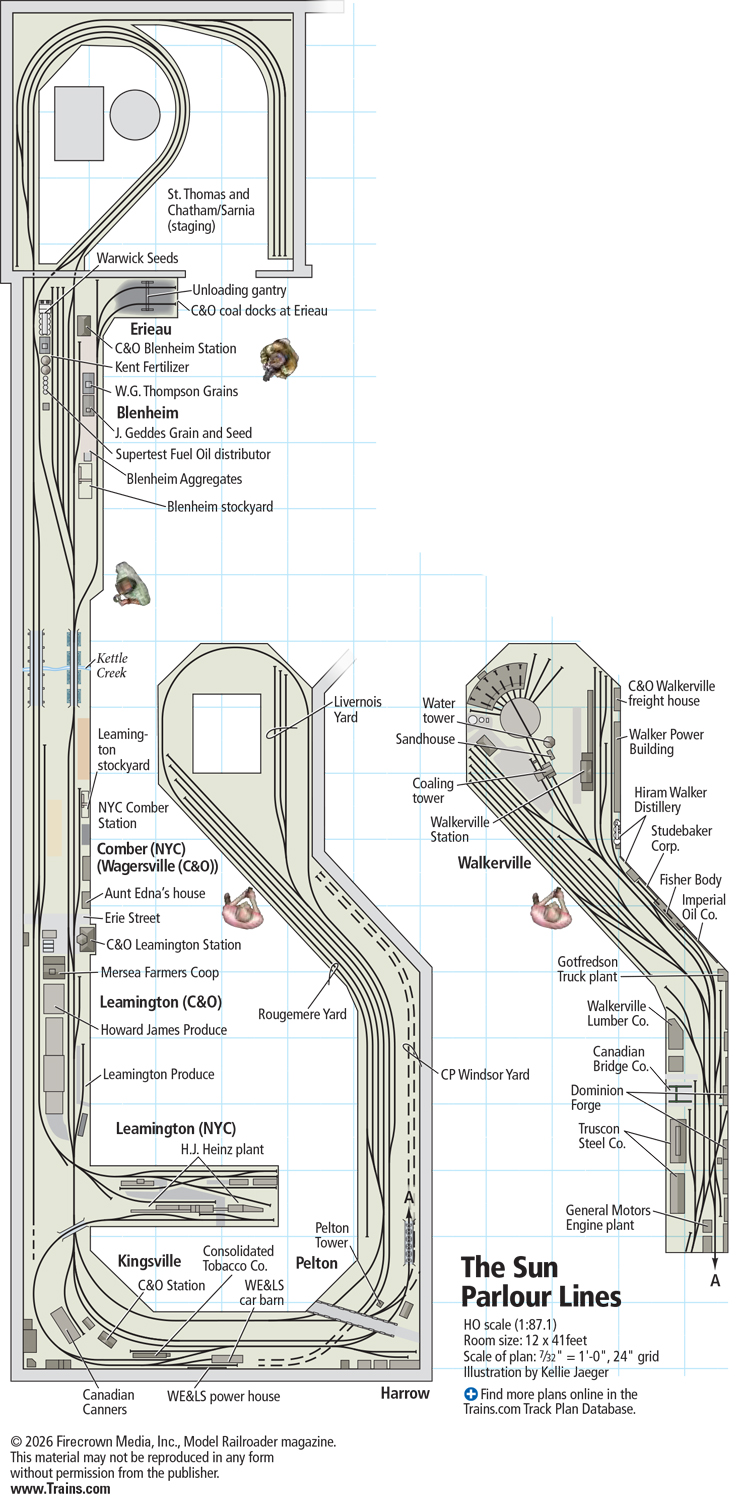

4. Running your thumbnail along the rail allows you to easily detect points that still need some filing. If your nail catches, the point needs some adjustment.

The turnouts shown in the figures 2, 3, and 4 have metal straps between the points. This adds strength, but also introduces a probability of momentary shorts as a metal wheel passes and the back of the wheel could touch the point if the point is too close to the stock rail.

Often this momentary short is not a problem for regular DC electrical systems.

This is considered to be a “non-DCC friendly” turnout and may cause DCC systems to stop and “reboot” excessively.

Reynold

Puyallup