The following is a series of edited excerpts from an interview conducted by David Popp with Stacey Walthers Naffah, president and CEO of Wm. K. Walthers, Inc. on April 21, 2025. It is part of Trains.com and Model Railroader‘s ongoing coverage of U.S. tariffs. Click here to watch the complete video interview on Trains.com Video.

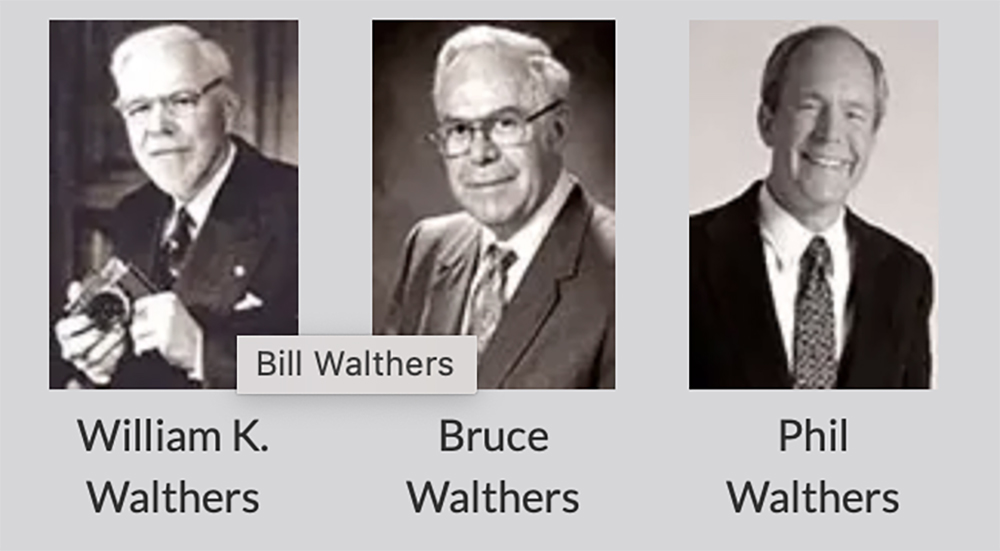

David Popp: Tariffs continue to be on everybody’s mind, and with the extensive changes in the tariff rates yet again, it is producing some interesting challenges for those within the model railroad industry. Joining me today is Stacey Walthers Naffah, CEO and president of William K Walthers, Inc. It’s a company with a 93-year history of producing and distributing model railroad products. And so, Stacey, thank you so much for joining us today.

Stacey Walthers Naffah: Yes, thanks so much for having me. And thanks for the opportunity.

David: How much of what Walthers produces and sells is U.S. made?

Stacey: So, we have kind of an ecosystem in our industry and, not surprisingly, since we’re in the business of replicating the big world in miniature, we do make some things domestically and we make some things overseas. It’s the same with most of the model railroad industry. But let me back up here.

We are both a producer and a distributor. So those answers are a little different depending on which hat I’m wearing. As a producer of model railroad equipment, we do all the design work in-house for our Walthers branded products, whether it’s track or freight cars or locomotives or our Cornerstone structures, all that design work is done right in Milwaukee, Wisconsin.

We then produce many of those products with long time partners overseas. So, our supply chain includes contract manufacturers in China, Vietnam, and Taiwan. We also do some work with European suppliers; it depends on product category. For our Walthers brand, we make locomotives primarily in China, but we might make our structures primarily in Vietnam or Taiwan.

If you now lay that on top of all the other products that we distribute and sell, and we represent some great vendors and brands that have been around for a long time, they have the same supply chain as we do inside the industry.

So, if you’re making locomotives, it’s primarily happening in China. And if you’re doing structures, you might be manufacturing it in similar places. But that’s not the only place that’s happening. There are domestic manufacturers too, and we’re also proud to represent them. When that whole ecosystem [model train manufacturing] comes together, nobody can do the entire thing without relying on specialized skill sets that have really been developed overseas over many years.

Many product categories are heavily reliant on China and Southeast Asia. They have the skill set, they have the supply chain, and they have the team members that they’ve developed in some cases over 30 years or more.

David: I think a lot of people fail to pick up on the fact that the system that’s in place; these factories that make all of the specialized parts for locomotives and put all the little grab irons and everything else on we modelers love, they didn’t happen overnight. It’s taken that industry [model trains] a long time to spool up to make those products and get them to the level we see and enjoy them today.

Stacey: Yes. [They can make] models that operate well and look great for a price that you can afford. That’s just the reality of it; you have to choose one. You might be able to have all those things [here], but it won’t be for a price that you can afford. And, the experienced labor force, the people who are able to do that really highly detailed work for our contract manufacturers, these are really good teams that we’ve been working with for a long time. We rely upon them for their skills, and they’re really important partners to us.

David: Training is important. As you said, you rely on them for their skill. It takes a long time to train people to do those things. You can’t just grab somebody off the street for this, can you?

Stacey: No. There are domestic manufacturers. We’re proud to represent Micro-Trains and Accurail and some of the other great, [domestic] manufacturers. They’re doing things right here and that’s wonderful. For Walthers to try to do the same thing for a locomotive, which is really the most complex of all the things [we make], that’s really hard to imagine. I don’t know how we could do that here. We can talk about it and explore it, but it would take a lot of time and a lot of investment to figure it out.

So, then you think about, “Well, what if I move it somewhere? Would I go to India? Would I go somewhere else?” For some products we’ve been talking about that. But you can’t just pick it up and move it. That also costs dollars that I would have to invest, as well as time that we’re then not spending on bringing the next best product for you.

Businesses have only so much money they can invest. And so where are we going to put it? We have a system that is working really well with partners that we trust; we’ve developed a relationship with them over the years, and we’d like to let them keep doing what they’re doing. The economics of it are becoming challenging. Any way you look at it, at the cost to do the business as we do it today, meaningfully shifting back to the U.S. in its totality is not economically viable.

David: No, I wouldn’t think so. Just over three weeks ago there was a 20% tariff on products coming from China, and everyone was scrambling to figure out how to make it workable. Today it’s a 145% tariff on product coming from China. How does a manufacturer even begin to cope with that? Or do you just stop production for a bit?

Stacey: This has been a really interesting leadership and management challenge for me and for my team and for a lot of the businesses in the industry. We’ve been talking to each other to help advocate for our position and explain it. But, yes, everybody’s really trying to figure out what to do.

There’s been a lot of dialogue about pausing or shifting, because there’s some really concrete examples of why we can’t just bring this product in and pay the 145% tariff on it. That is what’s facing us right now, and I’ve had to shift all my focus. Anything that I was thinking about growing the business, or you’ve heard of us doing some neat things about senior living or youth or some of these cool programs, those are literally parked on the sidelines because all of my time is being spent navigating exactly what we’re talking about. And I pretty much imagine that the same is happening for every other business that’s working with an overseas supplier.

For example, we had a shipment, two shipments, actually, that we thought were going to come in at a 20% tariff. In March, they were literally on their way to us, and we’d made a decision to route them through Vancouver, which is standard for us to have them to enter either through a US or a Canadian port. We’d then bring them here and deliver the products to everybody. We thought we would be able to absorb some of the 20% tariff and then maybe have to increase our price a little bit to offset it.

Because the shipment is going to Vancouver, and it would enter the U.S. after the date where the 145% tariff was announced, we will have to incur that tariff on that product. If I let both of these containers sail across the border and let the tariff get incurred, that’s $450,000 of tax that I have to pay.

David: That’s $450,000 tariff for just two containers?

Stacey: Yes, this is onerous. Our industry is made up of small businesses. We’re probably one of the bigger businesses in our industry. I can’t absorb that cost. Let’s say I could do it once. I can’t do it for all the containers that we were planning on bringing in.

So back to your question, yes, we have paused to regroup and figure it out.

Imagine all of those brands that we distribute. Whether it’s Broadway Limited, or Atlas, or somebody else, they’re thinking about the same thing. Imagine if all those things just came through their standard course across my desk. I’m going to have to essentially pay more for everything that’s coming at me. It’s not a sustainable model.

So yes, there’s a lot of pausing, regrouping, figuring out what’s the right thing. Our suppliers have made this product. We need to pay them. We’re always going to be a good partner to them. They’ve been a good partner to us. And so, there’s a lot of decision making that has to happen to figure out how to get us from where we were three weeks ago to where we’re going to be.

David: Are there no rules in place for product already on the water when the tariff changed – you get no grace period?

Stacey: It’s the last place that it moved across the border. So, in this case, it’s timing.

David: Because it’s coming into Canada before coming to the US?

Stacey: Yes. Trust me, I asked if we could move the shipment. Can you turn around? Can you go somewhere else? We’ve learned a lot. There’s likely going to be the supply chain person in the audience who says, “Well, if it was in March, you should have been shipping to Long Beach and not Vancouver.” We’re figuring it out.

It doesn’t matter if you’re in the model railroad industry or not, everyone is trying to decide, are you going to ship? Are you not going to ship? Customers should expect some disruption in the market.

David: Walthers has a very long history. Have you ever had to deal with tariffs like this before?

Stacey: To my knowledge, no.

Our business was founded in The Depression. In 1932 my great grandfather had another business that was failing. He was definitely an avid [model train] enthusiast, and he started this business in the depression out of a love for his hobby. I think that with our Depression kind of roots, our business shows that we’re pretty scrappy and tough.

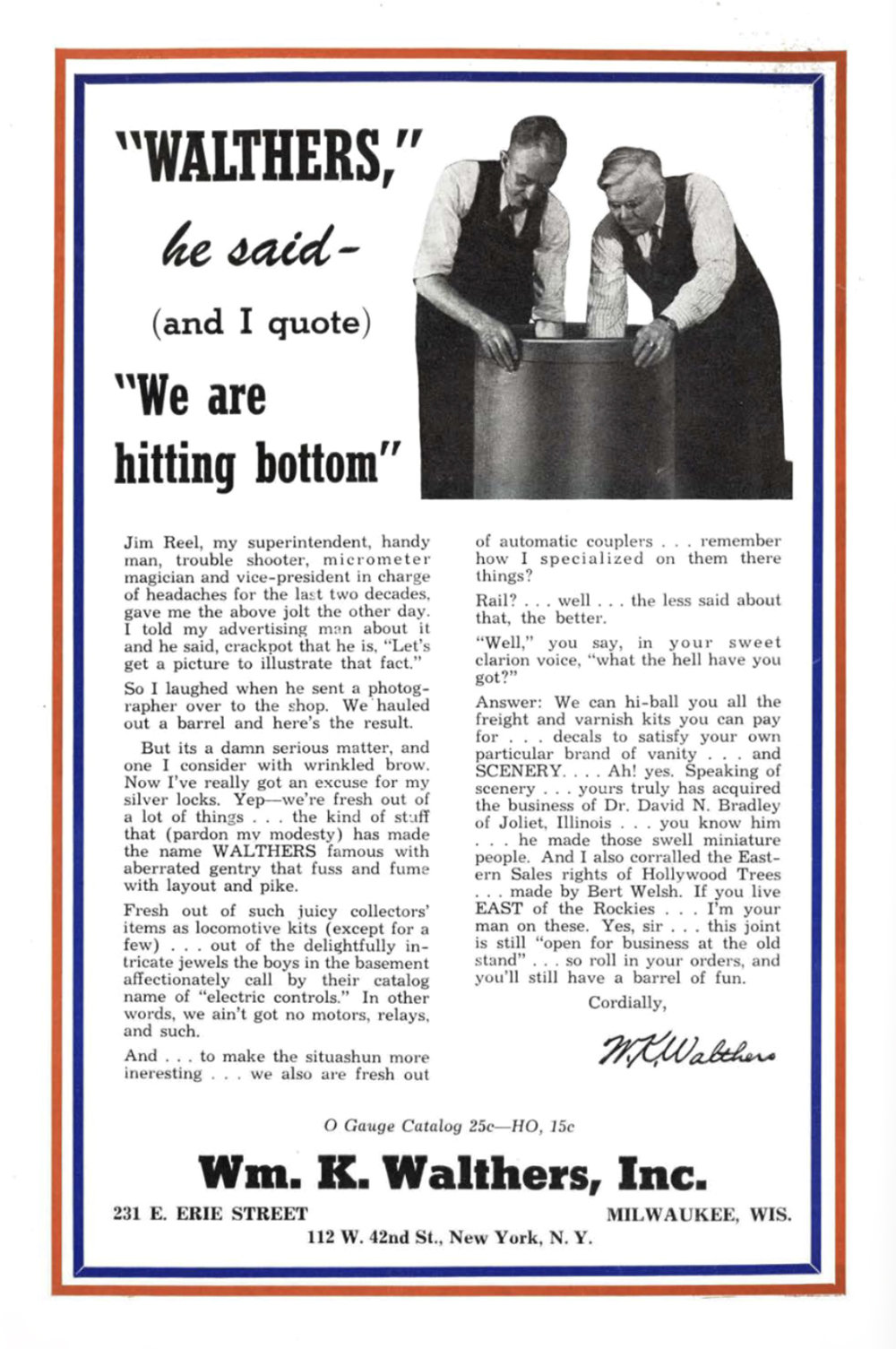

It’s been through a lot of stuff. We have a pretty famous ad that I think actually Kalmbach participated in at some point back in wartime [World War II]. “We’re scraping the bottom of the barrel to go get materials to make stuff.” That was a pretty pivotal moment for Walthers.

We were able to be excluded from the tariffs back in 2018 and 2019. There was a Section 301 tariff exclusion process I did participate in; we participated in it as an industry and didn’t get hit by tariffs then. So, on the tariff side, no. Walthers has not been through this before, but we’ve had other big shocks to the business system. Being 93 years old as a company, we’ve seen a couple things.

David: Speaking of the industry, you’re fairly well connected with many of the other key players. Largely, you distribute their products to some degree, but you’re also involved in all sorts of industry associations, so you see these people all the time. How are your industry partners coping – or are they?

Stacey: I would say that they are [coping]. The ones that are in the product categories that I described are pretty stressed out. They’re just trying to figure it out, like us. That’s the cool thing about our hobby, how collegial it is. We all want hobbyists to be able to have fun. And none of us want to be political. It’s not a political thing that we’re even trying to express here. It’s just the impact of policy. But I think we’re trying to get our story heard.

David: So, at this point, can you talk about the coalition of hobby manufacturers?

Stacey: It’s a group of people in the industry, including manufacturers, publishers, and also some hobby shops who have come together who say, “Hey, we’d really like to be considered to be excluded again.” We’re hopeful that [trade] negotiations can go well, but we’re caught in the crossfire here. So, we would like to be excluded.

There’s been some mobilization of effort that’s being combined with the HMA [Hobby Manufacturers Association] and the World’s Greatest Hobby and maybe NRHSA [National Retail Hobby Stores Association], and then a scattering of companies that all are working to get our message as clear and as clean as possible. We need others to know that we’re seeing an outsized impact on our businesses and get that message out to people who are not in our industry.

There’s already been letter writing campaigns that have gone to government officials in the appropriate channels with very straight-ahead messaging. And I’ve been well supported by Tom Hedrick at Atlas, Jason [Shron] at Rapido and Shane [Wilson] at Scale Trains; were all talking. In some cases, we’re talking this through even though we don’t always work together; Shane and I don’t necessarily have a business relationship other than being in the industry together, but we respect each other a ton and we want the same outcome here.

It’s been really nice to see how people are helping out to coalesce around a common message and then get that message out to the people who could make an impact for us – local elected officials.

David: I’ve heard you explain it earlier that even though a product is made in the United States, a lot of times components don’t necessarily originate in the U.S. Can you tell us a little bit of what that looks like?

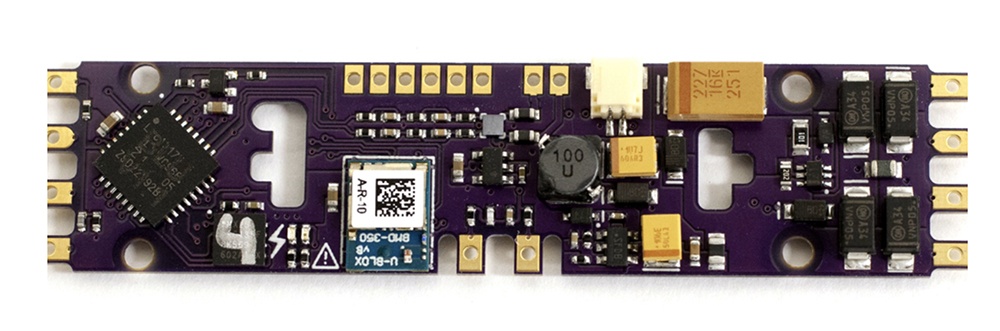

Stacey: I’ll do my best to represent it. I feel obligated to talk on behalf of the industry as a whole, which does include domestic manufacturers. One of my collegial friends that I have in the industry is Nancy Workman from SoundTraxx. She and I talked about the [tariff] impact on domestic manufacturers.

Nancy said that while they make things here in the U.S., her componentry comes from Asia. For SoundTraxx, being able to get what they need is still effected. And there may be a double whammy of having to possibly ship finished decodes back [to China], only to be imported again.

David: SoundTraxx decoders go into a lot of locomotives that are manufactured on the market. So, they actually make them here and then ship them back to China?

Stacey: Correct. So, as you can see, there’s complexity to it. This is an integrated ecosystem of the supply chain of all these companies where I might make one product and somebody else makes another product, and then a modeler can put it all together and make their layout. It really is a replication of what’s going on in the real world.

I do know that there are some [manufacturers] that do everything on site. I think Kadee pretty much sources everything domestically. But I want all businesses, I want all hobbyists, I want everyone in the model industry to be successful. And this policy is detrimental to that.

David: Let’s talk a little bit about exemption. You mentioned in 2018 the industry was exempt, correct?

Stacey: Yes.

David: So how did that occur?

Stacey: I took over Walthers and the role of president from my father, Phil, in 2018. I think it was probably around 2019 that we were doing this [the tariff exemption]. When we heard about it, there was a formal exclusion process that already existed. I just wrote a letter to the U.S. Trade Representative at the time, Lighthizer [Robert Lighthizer, U.S. Trade Representative, 2017-2021], and I wound up expressing my position and getting Walthers out.

I then got called by Fox Business Network and ended up representing what we had to say as one of these little stories that people gravitate to on an issue. But beyond that, I didn’t do much.

As I’ve come to learn through talking to people in government, there was a lot of enthusiasm happening behind the scenes before that formal process was created. The toy industry has a big voice. The toy supply chain is much like ours, and they need the same stuff we do. They have similar locations where they manufacture [products]. And so, whether it be a lobby, or however you want to call it, the industry association for toy manufacturers was advocating behind the scenes to ultimately get that exclusion process established.

My hope is that all this energy that’s happening right now for a lot of industries, including toys, will help create something similar. Our position for the coalition that does exist is that we are not a national security threat. I’m hopeful that perhaps a lot of the letter writing that’s already happened and the interviews like this and the other ones that people are doing might, catch somebody’s ear and enable them to consider excluding certain categories. There have been categories that have already been excluded between three weeks ago and now, such as electronics.

David: Here’s hoping then. Right?

Stacey: I’m a big believer in hope, but I also think you’ve got to have action. Action is what we’re doing now and trying to be as effective as possible.

David: With the vast bulk of model train stuff being made overseas. Is there a way that you can minimize risk?

Stacey: It’s interesting and of course we’ve been talking about this. You know, this is something that I think people are sometimes frustrated with, like “why didn’t you do this earlier? Why haven’t you found a place?” We’ve had the same conversations that I shared with you at the beginning of the interview, and it is very challenging and very costly to do these things.

We can mix up some of our suppliers. The fact that we’re in Vietnam is a risk offset. So, we are looking for other suppliers as well. I’m very interested in exploring how 3D printing can be more effective for us. I’m very interested in contemplating that perhaps there are sections of our business that could come back to the States. I have friends who are manufacturers in the States, and I believe me that I’ve been taking them out to breakfast. We’ve been talking a lot.

But, again, it’s not a light switch; it’s an investment. It’s the same dollar that I would have spent on a technology project or tooling a new product or something for my team here at Walthers to make it a better working environment.

It’s the same dollar. So, you have to figure out how to invest that prudently. And with uncertainty that becomes very difficult. Let’s figure it out. And if there is a path forward where we could bring things back here or mitigate risk in a different way to keep the product flow going, I’m all ears.

David: Do you think that something positive will come out of the whole tariff situation?

Stacey: I am a silver lining kind of a person. I’ve been through enough stuff in my life where I just think that’s the right way to look at it. I do think it [might] accelerate some things. I think that one of the coolest silver linings I’m seeing right now is just how many people want to mobilize to help each other.

I love seeing people come together. What a great opportunity to brainstorm together on how we might be able to all benefit from this.

Like I said, we’ve been in business for 93 years, so we’ve been through some stuff. I’m hopeful, and I’m also taking action to make that remain the case. And I want to do my very best to support the other businesses who are who are struggling to get through this too.

David: Well, Stacey, while talking about tariffs has been fun, let’s switch gears a bit and talk about Walthers. It takes someone who is fairly unique and has a lot of passion to run a business in this industry. What excites you about model trains?

Stacey: I get really excited about it. I had a completely different career, and I came back to this business because I got excited about being part of the family business. But really, it was led by my son Jack, who when he was four was a train-crazy kid.

David: I was going to ask if any of your kids were into trains.

Stacey: When Jack was four, we went to the Day Out with Thomas, at the Union museum [Illinois Railway Museum, in Union, Ill.]. I was living in Chicago with my family at the time and working on Michigan Avenue with big ad agencies and big clients. It’s why I know about big business.

So, and we drove down to do that [Day Out with Thomas], and I looked around and I saw a bunch of parents like me and their kids, and I also saw that our industry wasn’t there. It wasn’t there to greet that mom and that kid and this yuppie from Chicago, because that’s where we’re where we were living at the time, to say, “Hey, train crazy kid, here’s what you do next.”

That was a real spark for me. If you ever came to my office, you’d see the picture of me and my family in front of big Thomas. That was a moment, and it coincided around the same time where we were had young kids and were thinking about moving out of the city.

Also, at that point our business turned 75. There was a big event, and my grandfather, Bruce, who ran the business for a long time, was not doing particularly well health wise. He had stayed out in California for that event. But he sent a video and he talked about how the greatest joy of his life was working with his father and his son.

I was sitting there and something happened that was like the Thomas thing; the data points came together and [I knew] I needed to give this a shot. I had done my graduate work, and I had studied family business. That’s when I really imagined coming back.

It’s this passion for the idea that we could really make this hobby persist into the next generation; it’s what drives me every day. I love serving the people who are enjoying it today. But for me personally, it really goes back to my train-crazy kid.

You thought I talked a lot before about tariffs. I could talk a lot about this topic too because I think we have a real opportunity here. While Jack isn’t currently a modeler, he’s in college now and he’s into Lego, and he is a STEM kid.

If we can capture just a small fragment of the kids who are either train crazy or Lego kids, or STEM or STEAM crazy and convert them into our hobby, what a value that will create. They’re going to have so much fun and learn so many things. That gets me super excited.

And then I also think we can be a fulfilling opportunity for people to enjoy their retirements, learn a lot, and connect with others. I think that the thing that gets me most excited, and we talk about this a lot at the office, is building a connected community, where the little things matter. Bringing people together gets me really excited.

David: Some of my favorite moments of model railroading have been sharing with other. Being part of a group of guys that just get together on a regular basis and run trains or work on somebody’s layout or just talk trains. It’s nice to be surrounded by people who have like interests.

Stacey: Yes, and you’re learning from each other too.

It’s incredibly rare to have a business that makes it to a fourth generation. My great grandfather wrote a book in early days. I have that on the back of my credenza. It’s “old language” now, but in it he talks about how the captains of industry and the everyman are the same, and they’re always learning from each other. That is living and breathing in our industry every day; people coming together from all different walks of life, all different skill sets.

My mom was an educator. I was a camp counselor. I love the idea about bringing people together to share experiences and learn from each other.

David: Talk to me more about the outreach that Walthers has been doing recently, because you guys are doing some really cool things. I know you said some of them are on the back burner right now because of tariffs, but I hope they don’t stay on the back burner long.

Stacey: Don’t worry, they’re still going. It’s just like a little hard to get them all done. So, I started this when I came back to Walthers, and when I took over in 2018, I hired some really smart people who have accelerated the things that I had imagined that we could do.

We’ve got our National Model Railroad Build Off in multiple categories.

In particular, and this goes back to my care for youth and new people getting in the hobby, I think it’s a nice way to have a youth category. There’s just been some neat ways that we’ve been able to engage with people. We also have a college scholarship. I think we’re in our fourth year of that. It’s for people who are model railroaders but are also studying in the STEM and STEAM fields. We are proud to support their education.

We’re doing some really neat things with youth and senior living programs. They’re three-step programs that includes levels for Build a Scene, Build a World, and Build a Club.

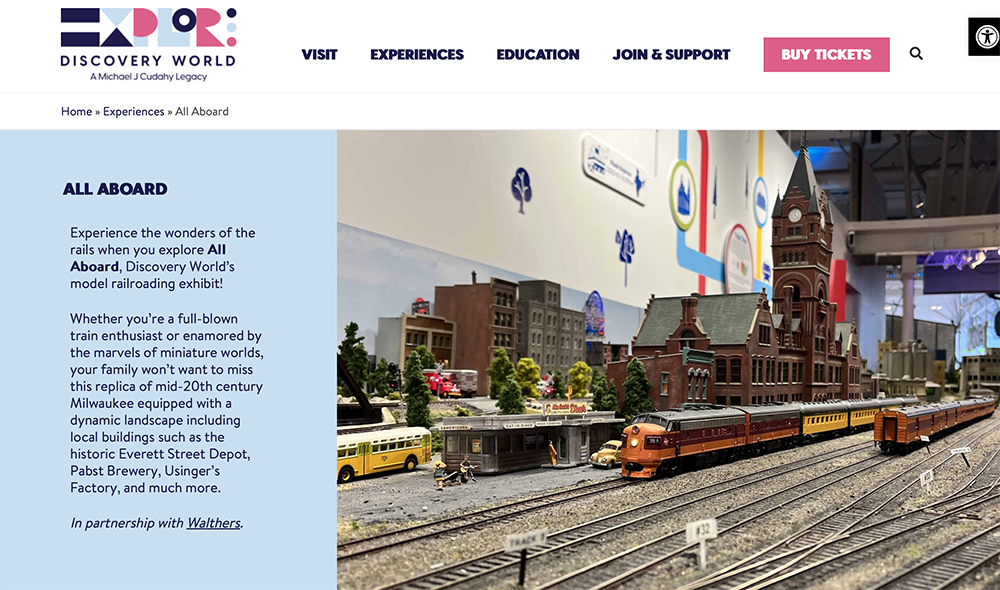

We’re hoping to put a lot of our energy this year into rolling out those programs, as well as partnering with organizations like Discovery World here in Milwaukee and other science centers on the youth side. Then there’s senior living communities that are looking to engage their residents and enable them to still enjoy their hobby or possibly start a new hobby that they’ve never experienced before.

David: You’ve already done work with Discovery World, correct? I remember the one in Milwaukee has a model railroad – we’ve filmed it.

Stacey: Only took me 12 years to get it in there. I’m persistent, if nothing else. It was a wonderful donation from a model railroader who passed away. He donated it, and his family was incredibly generous. Discovery World graciously gave us the space, and they’ve taught their team members how to operate the layout.

My hope is that getting the layout there was just step one. We’re going to do some educational outreach programs there, as well as summer camps. So that will be hopefully phase two. And if we can figure it out here in Milwaukee, maybe we could roll that out to other science centers.

David: Of all the things that Walthers has done over the years, is there something you’re most proud of?

Stacey: I’m just really proud to be a part of a family business that figured out how to do it for 93 years. I’m ridiculously proud of that. I have always respected my dad tremendously. He is a phenomenal human being and I always knew it was challenging. I had no idea until I was in the seat. I respect the integrity in which he and the generations before him have run our business.

David: Since you took up control of the company in 2018, you’ve had your hands full. You we’re dealing with tariffs then. Then we went to Covid and supply chain drama, and now we’re back to tariffs again, but on a scale we’ve not seen before in this industry. You’ve not necessarily had an easy time, have you?

Stacey: It was a good time for my dad to retire! Actually, he’s now chairman of the board and still supporting us. But he’s also truly been able to enjoy his retirement. We have a lovely tradition that he had with his dad, which is we usually meet on Fridays for breakfast to touch base, and he gives me counsel and then he gets to go do his thing.

Right now, he’s getting pulled in a little bit more than he might want to be, but he’s always willing to do the right thing. And that’s what my team’s doing too. I just I’m really proud of my team for rallying. We’ll get through it.

David: Any new products on the horizon for Walthers that you want to share or talk about it?

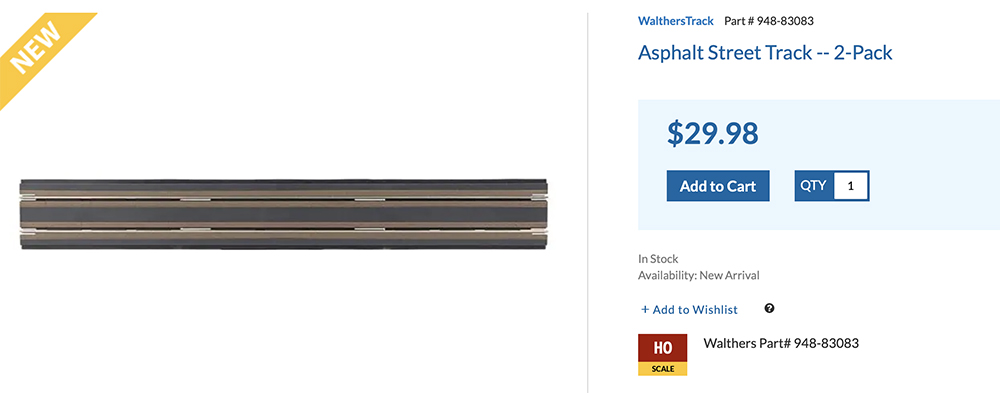

Stacey: We’ve got a lot of stuff going on and some exciting things we really would like to be able to get to you. We’re very proud of our track.

David: I got to see a sample last week of the new street track. I’m looking forward to working with that. It’s going to be fun.

Stacey: Yes, that’s cool, and we’ve got we’ve got a lot of other stuff up our sleeves. Some new models in the Cornerstone series, always. We try to spread it out over all of our categories to make sure that we’re hitting all the marks. So, I don’t want to play favorites to any of my children right now.

David: Stacey, thank you so much for joining us. Is there anything else you’d like to share before we go?

Stacey: I just hope people can keep having fun in their hobby. And if you’re so inclined and you want to learn more about what we’re doing to advocate for a tariff exclusion, reach out. Know that we’re not trying to get in the political dialogue. We’re just trying to advocate for the small businesses that comprise this really special hobby and the industry that I’m committed to supporting.

It should be remembered that the hobby manufacturers didn’t move production offshore to provide more affordable or better quality products to the consumer. It was to increase profits. The complaints about tariffs indicate that they have no desire to create American jobs to manufacture products for Americans to buy. The arguments about pricing is phony.

I was really glad that David Popp interviewed Stacey Naffah extensively on this topic. What a fantastic interview! The heart of Stacey’s leadership really shines through as she works with leaders throughout the model railroad industry to mitigate and hopefully eliminate these burdonesome tariffs which could potentially have devastating impacts on the industry as a whole.

What an excellent and illuminating interview. It really exposes the challenges facing model train industry leaders as they try to cope with the uncertainties associated with the current tariff situation. Thanks to Stacey Naffah and David Popp.

I would like to know how Walthers is planning to protect their proprietary property to prevent overseas bad actors from confiscating Walthers’ property. This happened with Atlas track a few years ago. And what would it take to begin producing some items domestically. Thanks