History

The Prototype I1s was developed for the Pennsylvania Railroad in 1923 by Baldwin Locomotive Works. After the overall tests were completed, results showed that the I1s outperformed the roads L1s Mikado’s by a whopping 41% more horsepower while consuming 12% less steam.

Beginning in the late 30’s, the original I1s underwent a revision of the cylinder steam vents to admit steam for 78% of the stroke. This boosted attractive effort from 90,000 to 96,000 lbs and made the new class I1sa. Through the years, many I1s engines were changed over to the modified I1sa design. By July 1947, the 598-unit fleet was divided into 109 I1s and 489 I1sa locomotives. They remained in service until the end of PRR steam in 1957.

Perhaps the most famous hangout and the final stomping ground for the I1sas was the Shamokin Branch, where they handled ore trains easily weighing in at 9000 tons in teams of three or four engines, sometimes even managing little more than a walking pace…

The Model

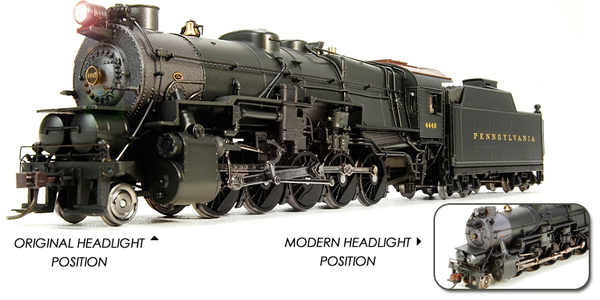

Precision Craft Models I1sa comes in a few different setups:

Original Headlight with 90F82 Tender

Modern Headlight with 90F82 tender

Original headlight setup with 210F82A Eight Axle “Coast, to Coast” tender

Modern Headlight with 210F82A Eight Axle “Coast, to Coast” tender

The run is also slit between DC only units without sound, and units equipped for DC or DCC operation with sound.

I purchased a copy of PRR 4268, which is Modernized I1sa equipped with 90F82 “Short” tender, and has QSI Sound.

Out of the box, this is one impressive unit. Like the prototype, the I1sa with 90F82 Tender is noticeably shorter than a Coast-to-Coast Tender equipped M1b. The unit measures 11-1/4 inches from front to rear coupling faces, and 2-1/16″ from the railhead to its tallest point. While I do not have access to any means to check the measurements against prototype drawings, the unit does check out against prototype photos.

The I1sa follows the traditional setup of most of Broadway Limited imports and Precision Craft Model’s steam locomotives. Both the engine and tender are composed of Diecast metal chassis with ABS Plastic Shells with many additional freestanding details and separately applied parts. There is even a crew sitting in front of the detailed firebox backhead.

The paintwork is well rendered, and under my lighting, captures the proper look of the PRR’s Characteristic DGLE (Dark Green Locomotive Enamel or Brunswick Green), while the smokebox is painted a Graphite color. Like the real units, the tender deck appears to be an oxide? Red, and the cab roof painted a mixture of black and oxide red. The lettering is the correct shade of gold and even closely matches photos in “The Pennsylvania Railroad: The 1940’s – 1950’s; by Don Ball Jr. Under a magnifying glass, the builder’s plate and Tender assignment plates are even legible!

Mechanism

The PCM I1sa is a smooth runner out of the box. Power is provided by a five-pole can motor and flywheel transmitting power to a well-positioned gear tower. Like other Broadway Limited Imports steamers, motion is transmitted to the remaining four axles through the rods. The first and fifth axles are sprung to allow some lateral movement. Like the real-life counterpart, the third set of drivers are “blind.” This was a trademark feature on many PRR steamers. (The M1b sported two sets of Blind drivers; one on the second axle, and one on the third). This was perhaps not only a smart move on the prototype, but also gives more clearance on the HO model. The engine and tender are connected by a metal drawbar with two notches, and an eight pin multi-wire plug. This connection provides power to and from the engine; to the locomotive headlight, and to control the QSI sound unit.

Using an MRC Control Master 20, I was able to get the engine’s well-rendered QSI Sound system to fire up at the notch seven. The engine began moving at notch eight, and was moving at the right pace for an ore or coal drag by notch eleven. The speed range for this engine seems in line with the prototypes 55 MPH typical top speed. At speed the unit moves about as smooth as a Swiss watch. (NOTE: After connecting the multi-wire plug up, you will want to center the wires and keep them centered to provide the least resistance to flexing around bends. Also avoid continuous plugging and unplugging, as this exhibits excessive wear on the plug unit.) After testing, the I1sa (with 90F82 tender) will make an 18″ Minimum radius as stated on Broadway Limited Imports / Precision Craft Models Website. My unit was tested over one 18″ Radius and three 22″ Radius curves without problems. For pulling power, the fifth set of drivers is equipped with traction tires by default. A Hex driver and a standard driver are included in the box should you decided to remove the traction tires. During the course of test running, I handed one nineteen-car train consisting of Atlas, Athearn, Bowser, and Accurail Hoppers and boxcars, and one coal drag consisting of Bowser, Athearn, Atlas and Accurail hoppers, with ease. All cars are equipped with Branchline 33″ Metal wheel sets for better rolling and performance.

Using only the Control master 20’s handheld controller, I was able to access the whistle and bell. For the whistle, simply throw the direction switch in the opposite direction of movement to activate the whistle, and back to the proper direction to deactivate it. Doing the same movement fast will activate the bell. Repeat once more to deactivate it. According to Precision Craft Models, using a Quantum Engineer allows access to more sounds.

The QSI sound system, like the Blueline, features the startup and shutdown sounds, synchronized chuffing as the engines in motion, bell sounds two different whistles (The original Banshee whistle comes activated by default, but may be changed to a three chime.), air pump charging, and numerous other sounds.

There are two ways to adjust the overall volume of the unit, should you feel the need to. The first and easiest is to use the Quantum Engineer in programming mode and lower it that way. Since I don’t own one, I used the second route: using the potentiometer located within the rear of the tender. This is a somewhat difficult task that I don’t recommend doing often.

To do this, simply nestle a screwdriver between the metal floor of the tender, and the plastic structure (being careful to keep the wiring harness out of the way), and push upward carefully. This will pop the front of the tender shell free. At this point, you’ll be able to release the rear of the tender too. On the 90F82 “Short” Tender, there is a backup light that plugs into the PC Board and hinders the complete disconnect of the tender shell. I don’t recommend unplugging this either. Simply turn the shell at an angle out of the way, avoiding excessive stress to that lead. The Potentiometer is closest to the rear of the tender. On my unit it is a bluish plastic color with a slot in it for a small standard screwdriver. To lower the volume, turn this counterclockwise, or to raise it, go clockwise.

Overall, the Precision Craft Models I1sa is a must-have for anyone modeling the “Standard Railroad of the World” during the steam and Transition era.