The prototype. In 1923, the Southern Pacific Ry. purchased 10 Mountain-type 4-8-2 locomotives to replace some of its Pacific-type 4-6-2s on mainline passenger routes. These class MT-1 locomotives, as well as the MT-2 class acquired from the El Paso & Southwestern, were the only Alco-built Mountains that the SP owned. The other classes, MT-3, 4, and 5, were built by the railroad’s locomotive shops in Sacramento, Calif.

The MT-4 class locomotives were delivered between 1926 and 1929 and had similar characteristics to the earlier MT-1 and MT-3 locomotives. The Southern Pacific first assigned the MT-4 Mountains to the Coast Division. On that route the engines led the Lark and other first-class trains.

The MT-class Mountains hauled passenger trains until the end of the steam era. During the 1950s, the Mountains even hauled “commute” trains, making frequent stops.

The Athearn Genesis model matches drawings of an SP class MT-4 locomotive and class 120-C-6 tender found in The 4300 4-8-2s: Southern Pacific’s Mt-Class Locomotives (Signature Press).

The quality of the molded detail on the model is excellent. There’s even the correct builder’s information molded on the side of the delta-type trailing truck. The model also has the correct Worthington BL feedwater heater. Other separate detail parts include piping, handrails, whistle, bell, and safety valves.

Painted crew figures aren’t included, but the cab has a detailed backhead and glazing in all the cab windows. A folding cab apron bridges the 10 scale-inch gap between the locomotive and tender.

The overall finish of the satin black paint on the locomotive and tender is smooth, except for a dark spot of touch-up paint on the fireman’s side of the tender sill. All the markings on the locomotive are in SP lettering gray and match prototype photos, including the Harriman classification data under the engine number. The printing on the builder’s and superheater patent plates on the sides of the graphite-colored smokebox are visible under magnification.

The die-cast metal drivers are painted black with the correct gray stars painted on the axle ends. The SP used the stars to designate locomotives equipped with spring-pad lubricators. The running gear and the trailing truck and tender wheels are chemically blackened. The pilot wheels, driver tires, and the ends of the driver axles are bare metal, which would look more realistic if painted black.

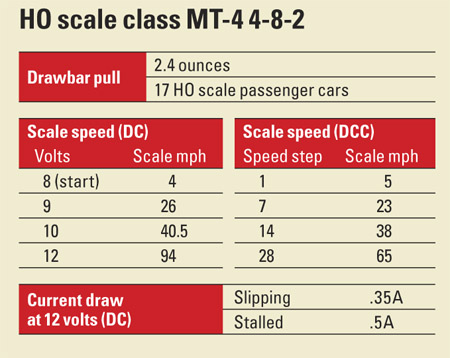

The mechanism. A five-pole skew-wound motor and brass flywheels are inside the boiler on top of a die-cast metal frame. A worm gear transfers power from the motor to a gearbox on the second axle. The drivers on this axle also have rubber traction tires. The side rods turn the other drivers.

The locomotive and tender come from the factory connected by a plastic drawbar. A six-wire harness connects the electronics in the tender to a socket under the rear of the locomotive cab. The DCC decoder and a downward facing speaker are inside the tender. An exploded engineering drawing is included, but disassembling the locomotive and tender isn’t recommended.

Using an NCE Corp. Powercab DCC system, the model had a more prototypical top speed of 65 scale mph at speed step 28. When I switched to 128 speed steps, the Athearn MT-4 crept smoothly at 1 scale mph at speed step 1.

The locomotive will run through 22″ radius curves, but looks better on wider radii, especially when hauling a passenger train. I also ran the model forward and back through no. 6 turnouts without any problems.

Dual-mode sound. When using a DC power pack the sounds are limited to

automatic effects, such as the air pumps, random steam release, and the exhaust sounds. You can trigger the locomotive whistle by sliding the direction switch back and forth while the model is moving. In DC, the MT-4 will only change direction when it’s stopped.

In DC, the exhaust sounds start before the model begins moving and are unsynchronized. I improved synchronization by lowering the auto exhaust configuration variable (CV116) to a value of 30. This setting still wasn’t perfect, and you need a DCC system to program CVs.

In DCC the exhaust sounds were synchronized from the factory at four chuffs per wheel revolution. I especially like the Tsunami’s Dynamic Digital Exhaust feature, which varies the intensity of the chuffing according to the load on the locomotive. You can also adjust the sensitivity of the effect.

Other CVs allow you to adjust the volume of individual sound effects, and an on-board equalizer lets you fine-tune the overall sound mix. Extensive user manuals listing all the programmable CVs for the decoder are available as free downloads at www.SoundTraxx.com.

The user-triggered effects in DCC include the bell, long whistle blast, coupler crash, and a water-stop sequence. There’s a separate short whistle blast command that you can use for train whistle signals, although this can be a bit awkward for a grade-crossing signal (long-long-short-long), since you must use two separate function buttons.

Espee steam-era modelers once had to look for brass models or undertake an intensive kitbashing or scratchbuilding project for an accurate MT-class locomotive. They can now choose an accurate ready-to-run MT-4 that works in DC or DCC and includes great on-board sound.

Price: $299.98 (DC), $399.98 (DCC sound)

Manufacturer

Athearn Trains

2883 E. Spring St., Suite 100

Long Beach, CA 90806

www.athearn.com

Road numbers (all Southern Pacific): Early version: nos. 4348, 4346, 4347, 4350. Late version: nos. 4349, 4358, 4360. Painted and unlettered models also available.

Era: 1926 to 1958

Features

Okay folks, I know that I’m a little late coming to the game here, but I have to chime in about dismal pulling capabilities of this model. I own four of these fantastically detailed locomotives but there is one fatal mechanical flaw that almost puts this model into the trash heap. If you haven’t already noticed or come across this on YouTube https://youtu.be/6gJlWPk8mbg

you’ll know that the number one and number three drivers are sprung. The spring tension is strong enough that it prevents the number two driver, which by the way has the traction tire, from making complete contact with the rail head. Now as stated in the video, I too take no responsibility for anyone screwing up their MT4 and turning it into a $400 door stop. The solution is rather simple. Remove the driver cover place and the trailing truck screws. Once you open up the mechanism, carefully lift the number one and three drivers along with their bushings from the frame. You’ll notice a spring in the bottom of the axel slot. Remove all four of them. Remember when reinstalling the drivers into the frame, you must seat the axel bushings completely so that the driver lines up properly with the other drivers. This requires a little force so use a foam cradle in order not to damage any of the exposed detail parts. Once you have reseated the driver bearings back into their slots in the main frame, take this moment to apply some lubricant to the main gear and the rest of the drivers. I used LaBelle #106 model grease on mine which is safe for use on plastics. Now replace the gear cover carefully aligning the contact wipers, then reinstall the screws and trailing truck. Place the locomotive on your test track and visually inspect that all the drivers are touching the railhead and that no one driver is lifting, especially the number two driver with the traction tire, off the railhead. Now that everything is properly in place, test run your MT4 and notice how much better the tractive effort is now after the removal of the springs. Again, I take no responsibility for anyone screwing up their model. Preform this modification at your own risk or have a competent model backshop do it for you.