A new idea. After World War II, the Union Pacific was shopping for the next big idea in locomotives. To minimize maintenance costs, the railroad sought a high-horsepower locomotive that could take the place of smaller units in multiple. General Electric, which had success with turbines in aircraft, suggested a turbine-powered locomotive.

Nicknamed “Big Blow” due to the turbines’ jet-like exhaust, UP no. 50, a prototype gas-turbine locomotive started extensive testing on the railroad in July 1949. After testing no. 50 for nearly two years and more than 100,000 miles, the UP ordered 10 more of the 4,500-hp units in March 1951. But unlike the double-ended no. 50, nos. 51-60 were single-ended, allowing a slightly larger fuel tank.

Fuel capacity was an issue in operation of the gas-turbines. They drank fuel at a rate nearly double that of a similar-sized diesel. However, the turbines were still economical, because they ran on bunker “C” oil, a cheap and abundant by-product of oil refining. In 1955, the UP added a 22,000-gallon fuel tender to extend the range of the gas-turbines.

The design underwent a number of changes, even during the production run. The turbines, which required a constant flow of fresh, cool air to run at top efficiency, worked poorly when run at slow speeds in tunnels. Hot exhaust gases would back up and get sucked back into the turbine. A new, backward-angled exhaust stack helped eliminate this problem.

The first-generation turbines took in air through square panels on the sides of the carbody, protected by stainless steel Farr grills. In 1953, the intakes were moved to the roof, and the Farr grills were removed. Our sample, numbered 54, includes the angled exhaust, roof-mounted air intake housing, capped front side grills, and fuel tender of a post-1955 unit. Other road numbers have different details, such as no. 51’s Farr grills.

The Union Pacific’s venture into gas-turbine locomotives ended in 1970, as demand from the nation’s growing plastics industry made the once-cheap bunker “C” fuel oil less cost-effective.

The Armour Yellow and Harbor Mist Gray paint on our sample is smooth and even. The fine black outlines on the red “Union Pacific” and number 54 are crisp and perfectly aligned. The red stripes on the top and bottom of the yellow section of the carbody are not the same glossy, opaque red as the lettering, though, and the overlap of the gray and red is visible.

The plastic body shell’s tooling is impressive, with finely molded details. The model’s major dimensions match those on prototype construction drawings reproduced in Thos. R. Lee’s definitive book Turbines Westward.

The model’s knuckle couplers are at the correct height, but their trip pins hung too low. I easily adjusted them with a pair of Kadee trip-pin pliers.

An inside look. Removing four screws that flank the trucks allowed me to lift the plastic shell off the one-piece, cast-metal chassis. The five-pole can motor and its turned brass flywheels are in the middle of the frame’s central tower, under a clear plastic plate. This is a good idea, as it protects the moving parts from dust that might be drawn into the body through the open exhaust vents directly above.

On either end of the frame are two 1.2″ spaces for the installation of speakers, with sound holes milled into the base above the end trucks. There are DCC decoder plugs on the printed-circuit boards in the back of the locomotive. A number of manufacturers, including QSI Solutions and SoundTraxx, offer or are planning sound decoders for the Athearn gas-turbine models.

Plastic universal drive shafts connect the motor to gearboxes on the two inboard trucks. The two sets of trucks pivot at this gearbox, which is above the locomotive’s third and sixth axles. Pivoting cast-metal plates extend from the inboard trucks to the outboard trucks. Spring-loaded screws attached to the end of each plate ride in slots in the ouboard trucks. The outboard trucks can float and pivot over a broad range of motion, which lets the nearly foot-long locomotive negotiate 18″-radius curves. The model would look better on broader curves, though.

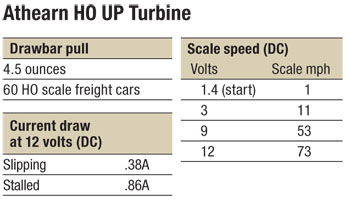

The Athearn model’s headlights lit and its five-pole, skew-wound motor started turning at just over 1 volt (V). The locomotive rolled smoothly at 1.4V, at a scale speed of 1 mph. At 12V the locomotive reached a top speed of 73 scale mph. This is only slightly faster than the top speed of 69 mph listed for prototype no. 50 in the 1950-52 Simmons-Boardman Locomotive Cyclopedia of American Practice.

Through all its speed tests, the model’s drive train operated smoothly and quietly. The unit’s weight and two flywheels added a momentum effect when starting and stopping the locomotive.

With Athearn’s new model, UP fans can keep the “Big Blows” rolling for years to come.

Price: With tender, $299.98; without tender, $229.98; tender alone, $89.98

Manufacturer

Athearn Trains

2883 E. Spring St., Suite 100

Long Beach, CA 90806

www.athearn.com

Road numbers: (all Union Pacific) with tender, 54 and 58; without tender, 51 and 60; tender not numbered

Era: 1952-62 (nos. 51, 54); 1953-64 (no. 58); 1953-63 (no. 60)

Features

All-wheel electrical pickup on locomotive (no pickup on tender); eight-wheel drive

Backup light on tender

Detailed cab interior

Eight- and nine-pin DCC decoder sockets

Five-pole, skew-wound can motor with dual brass flywheels

Interchangeable nose trim (above pilot)

McHenry plastic magnetic knuckle couplers at correct height

Minimum radius: 18″

RP-25 contour metal wheels in gauge

Weight: (Engine only) 1 pound 14 ounces. (Engine and tender) 2 pounds 2 ounces