Prototype. General Electric built 475 45-ton switchers for North American customers in the 1940s and ’50s. The 45-ton switcher was smaller and less expensive than GE’s 44-ton switcher.

The 45-tonner had two traction motors that drove one axle of each truck. An internal chain-and-sprocket drive or external siderods connected to cranks transferred motion to the adjacent axles.

The HO model’s dimensions match drawings in General Electric Industrial Locomotives 1924-1978 (DPA-LTA Enterprises, Inc.).

Appearance and construction. The Bachmann 45-tonner is available mainly in unlettered versions. The paint coverage on our sample is smooth and evenly applied. The yellow and white stripes on the hoods are straight, even where the stripes cross hood-access hatches.

The hoods of the model are a single piece of die-cast metal with well-defined molded detail. The cab and frame are plastic. The frame has molded safety tread detail on the walkways.

The cab interior features a single painted engineer figure and brake stand. Separately applied details include handrails, windshield wipers, and uncoupling levers.

The appearance of the plastic truck sideframes matches prototype photos. The axle-mounted cranks on each truck are connected by siderods that move with the motion of the wheels.

Mechanism. Removing the model’s body shell is a bit more involved than the two steps indicated on the instruction sheet. To remove the shell, I first removed the couplers from the frame and the press-fit handrails from the locomotive cab. Then I pulled off the press-fit trucks to expose all the screws holding the shell to the frame.

The plastic coupler pockets have plastic tabs that lock in place on each end of the body. Using a hobby knife I cut off the plastic tabs from each coupler pocket. Then I pulled each coupler pocket free and separated the body shell from the frame. (During reassembly, I used the now-modified coupler pockets without any difficulty.)

The can motor is enclosed in the center of a split die-cast metal weight. Two gearshafts transfer power to each truck gearbox.

The DCC decoder is mounted on top of the metal weight. This decoder measures 7/16″ x 27/8″. The press-fit plastic fuel tank on the bottom of the frame has a recess for a ½”- diameter speaker (not included) as well as sound holes.

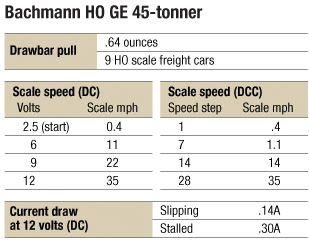

Although the decoder supports only 28 speed steps and has limited motor-control programming capabilities, the 45-tonner started running at speed step 1. User-triggered DCC functions include turning the headlight on and off (Function 0) and dimming the headlight (Function 1). I changed the locomotive’s address on a programming track using an MRC Prodigy Advance DCC system.

The headlights are constant light-emitting diodes. In both DC and DCC modes the headlights turn on and off according the model’s direction of travel. I switched cuts of six 50-foot cars on our layout.

The Bachmann GE 45-tonner is a versatile choice for modelers looking to add industrial motive power to their HO layouts.

Price: $125

Manufacturer

Bachmann Trains

1400 E. Erie Ave.

Philadelphia, PA 19124

www.bachmanntrains.com

Road names: Bethlehem Steel no. 22. Painted but unlettered: Red with yellow stripes and handrails (pictured), black with yellow handrails, green with yellow handrails, yellow with black handrails

Era: 1940 to present day

Features

All-wheel drive and electrical pickup

Dual-mode DCC decoder

E-Z Mate Mark II operating knuckle couplers at correct height

Five-pole skew-wound motor

RP-25 contour blackened metal wheels in gauge

Weight: 4 ounces