I recently reviewed two N scale diesel locomotives from Broadway Limited Imports (BLI) featuring Paragon3 Digital Command Control (DCC) decoders with Rolling Thunder (March and May 2019). Now, BLI’s floor-shaking subwoofer system comes to N scale steam power, with the Pennsylvania RR class T1 4-4-4-4. The prototype locomotive cut a stylish figure on the tracks but suffered from maintenance and traction issues that sidelined it after only a few years. The BLI version, on the other hand, runs as good as it looks, with smooth DCC operation, realistic sound, and impressive pulling power.

An idea whose time never came. The duplex drive seemed like a good idea on paper. Proposed by the Pennsylvania’s locomotive-building partner Baldwin in the early 1930s, the duplex drive bypassed the physical and practical limits of eight- and ten-coupled locomotives by splitting the engine into two independent units. With this design, it was theorized, cylinders could be smaller, mechanical stresses could be lessened, and side rods could be lighter, reducing hammer action. Baldwin was eager to prove the idea’s viability, as the company was facing fierce competition from Alco’s three-cylinder design, Lima’s Super-Power concept, and the growth of electric and diesel-electric locomotives.

There were problems right from the start with the two prototypes delivered in spring 1942. Futuristically streamlined by designer Raymond Loewy, the T1 was intended to pull the Pennsy’s flagship passenger trains. However, it had design problems – wheel slippage, repeated valve failures, and that long, rigid wheelbase – that weren’t solved by the tweaks made when Pennsy ordered 50 production T1s in 1945 and 1946.

The futuristic-looking T1 was supposed to be the ultimate steam engine, but it fit that description only in the sense it was the Pennsy’s last. In 1948, the Pennsy’s governing board decided to put diesels on point of its top name trains. The T1s were relegated to secondary trains. By 1949, most of them were in storage; the last was scrapped in 1953. None survive.

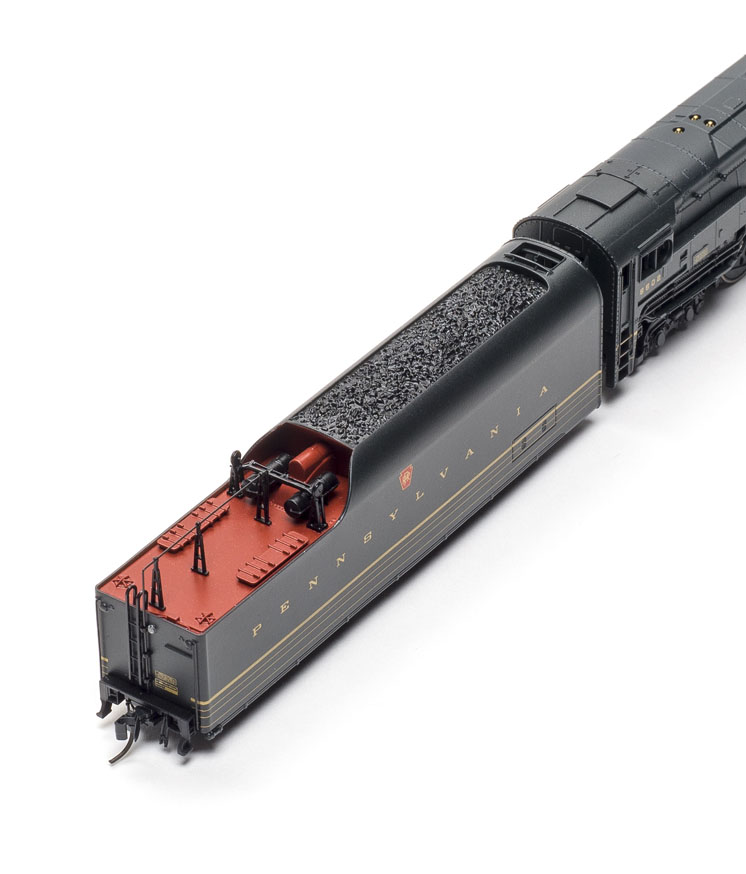

The model. With its pointed prow and porthole-accented pilot, Loewy’s prototype T1 design was a triumph of Mid-Century Modernism. Practical considerations took over for the production units, and the first batch delivered in 1945 had a more rounded nose and narrower skirts for better access to the valves. The 1946 batch replaced the streamlined pilot with a taller, boxier version without portholes and moved the PRR keystone onto the nose. This is the version depicted by BLI’s model.

Broadway Limited Imports’ N scale version closely resembles photos published in Model Railroader Cyclopedia: Vol. 1, Steam Locomotives (Kalmbach Books, out of print). The model’s dimensions likewise measured up to the diagrams printed in that book, including the wheelbase and the driver diameter. That’s a feat for N scale, a scale in which wheel flange depth often requires accommodations in this area. (It helps that the middle two sets of drivers are “blind,” or flangeless, to make the engine better take sharp curves.)

The model’s paint scheme also matched published photos. The Dark Green Locomotive Enamel (an almost-black shade of green some call Brunswick Green) was smoothly and evenly applied, and the Dulux Gold striping on the tender was crisp and straight. The lettering and numbers were likewise sharp. The tiny builder’s plates printed on the skirting weren’t quite legible under magnification.

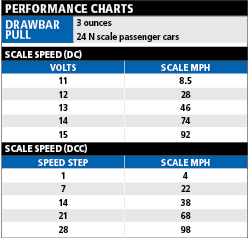

Sound-decoder-equipped engines take a lot of voltage to get moving, and BLI’s T1 is no exception. As I turned up the track voltage, the sound of a fireman shoveling coal into the firebox began a startup sequence at 9.5V. The engine started rolling hesitantly just below 11V; it smoothed out at 11V, moving at 8.5 scale mph. At the max output of our power pack, 15V, the locomotive rolled at 92 scale mph, close to the 100 mph speed limit imposed on the T1s by PRR rules.

To expand the locomotive’s voltage range, I used our DCC system to lower the value of Configuration Variable (CV) 252, Direct Current Voltage Minimum (DC Vmin), to 80. This allowed the locomotive to start rolling at 8.5V.

Each engine featured four exhaust chuffs per revolution. The amount that the exhaust sounds go in and out of phase can be adjusted with CV194, using either the DC Master or a DCC system. A brake squeal played when I quickly reduced the engine’s speed.

Rolling Thunder is Broadway Limited’s subwoofer sound system. A receiver picks up signals sent by a Rolling Thunder-capable decoder and plays the deep bass tones through the subwoofer, enhancing the sensation of standing trackside. The system worked well, vibrating the floor with each chuff.

Next, I tested the locomotive under DCC, which allowed more control over the sounds, letting me trigger the air pumps, coupler clank, and other effects. The decoder’s back-electromotive-force (back EMF) system automatically made the steam chuffs heavier or lighter depending on the load on the engine. I was pleased to find that I could also control that effect manually when running the locomotive, using function keys F5 and F6. (When stopped, those keys trigger the boiler blowdown and tender water sequence, respectively.)

The macro feature, triggered by function F27, records a sequence of operations like throttle changes and sound effects, then plays them back upon pressing F26. I tried it by pressing F27, executing several commands, then pressing F27 again to end recording. Backing up to my starting point, I pressed F26, and the engine went through its paces just as I’d done. You can set a CV to control how many times the sequence repeats. I can see this coming in handy when showing the layout at an open house or train show.

Finally, I hooked the engine up to our test bench force meter. With traction tires on its rear drive axle, the little engine mustered a muscular 3 ounces of pulling power. That’s enough to haul 24 full-length N scale passenger cars on straight and level track.

A dream denied. Maintenance problems kept the T1 from delivering the steam-power revival the railroad and builder hoped it would. But the Pennsy’s ultimate steam locomotive demonstrated that steam hadn’t reached its upper limits, and if it weren’t for the advent of cheaper-to-run diesels, who knows what might have happened? Though it didn’t prowl the rails for long, the T1 did it in style. If you model the last days of Pennsy steam in N scale, let BLI’s model prowl your scale rails.

Manufacturer

Broadway Limited Imports

9 East Tower Circle

Ormond Beach, FL 32174

www.broadway-limited.com

Era: 1945 to 1953

Road numbers: Pennsylvania RR

nos. 5502, 5506, 5517, 5528, 5533, and 5539. Also available painted (Dark Green Locomotive Enamel) but unlettered.

Features

• Blackened metal wheelsets, in gauge; middle four driver axles are blind, rear two have traction tires

• Brass whistle and valve details

• Die-cast metal body

• Electrical pickup on six drivers and all tender wheels

• Flywheel-equipped can motor geared to first and fourth axles; side rods transfer power to other drivers

• Magne-Matic couplers front and rear, at correct height

• Paragon3 dual-mode sound decoder with Rolling Thunder

• Recommended minimum radius 93⁄4″

• Weight: 6.1 ounces (engine and tender), 4.1 ounces (engine alone)

• Wire grab irons and other detail parts