The prototype. The Pennsylvania RR’s K4s were some of America’s best known steam passenger locomotives. Built between 1917 and 1928, 424 of these locomotives hauled PRR limiteds and locals systemwide. This model represents the classic K4 appearance common from the 1930s through the end of steam. It closely matches the prototype drawings published in the Model Railroader Cyclopedia: Vol. 1, Steam Locomotives.

The model is mostly die-cast metal with some parts cleanly molded in plastic. It has a boiler backhead in the cab along with seats, an engine crew, and a hinged deckplate between the cab and tender.

This model’s chassis captures the prototype’s appearance with accurately scaled, properly spaced 80″ drivers, lead and trailing trucks, and brake shoes. All of the wheels have RP25 contours and match the National Model Railroad Association standards gauge.

A Canon can motor is concealed within the firebox and drives a gearbox on the main driving axle. Power is transferred to the other drivers through the siderods. All the drivers are sprung and have textured metal tires.

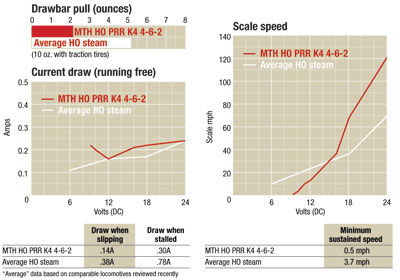

An extra driver set with rubber traction tires is included. The instructions show how to swap the rear drivers so the drawbar pull jumps from 2.24 to 10 ounces.

A great smoke unit is built into the boiler, and it’s timed to match the chuffing sounds. It has a small fan that delivers four realistic puffs of smoke for each driver revolution.

The tender has a neatly detailed body that has simulated electrical conduits, an air brake system, and water scoop. The model’s electronic system is concealed in the tender along with a pair of speakers.

The K4’s electrical pickup is a bit unusual. All eight tender wheels normally pick up current. If they lose contact, the electronic system quickly and automatically switches over to picking up current through the locomotive drivers.

The finish on our sample K4 was smooth with clean edges between the colors. Its sharp lettering follows PRR practices and even includes the cast tender class and identification plate.

We divided our testing into three parts: Senior editor David Popp conducted the DCC portion, Classic Toy Trains editor Neil Besougloff provided his expertise with the DCS system, and I conducted the DC tests.

Straight out of the box, the locomotive needed little programming beyond setting the address. As set up from the factory, the K4 performed well hauling trains around our employee club layout, the Milwaukee, Racine & Troy.

The K4 sound system offers a lot of features. While many are activated using the DCC system’s function buttons, the engine also provides a rich array of random sounds, whether the locomotive is in motion or standing still. And, by pressing F7, you can select one of nine options for the locomotive’s master volume without needing to reprogram the decoder. (You can also set the volume manually using a knob under the tender water hatch.) In addition to sounds, the locomotive has several other DCC function-activated features, including headlights (F0), a cab light (F5), and smoke effects (F8).

While the K4 ran well, some of the DCC features didn’t operate exactly as we expected. For example, function 8 activates the smoke, not the sound on/off switch as found on most sound decoders. Some decoders allow you to remap their functions using configuration variables (CVs) for uniform control of all the locomotives on a layout, but these remapping options aren’t listed in the K4’s operating manual.

In fact, according to the manual, the K4 has only 10 programmable CVs. And here’s another point to be aware of – some CV values are reversed. We found this out when we tried programming the K4 with longer acceleration and deceleration rates using CVs 3 and 4. After some experimenting, we discovered the values work opposite of most DCC decoders. On the K4, the lower the value placed in CV4, the longer it takes the locomotive to stop.

However, these details are relatively minor in the grand scheme of things. In DCC mode, theK4 was an enjoyable model to run.

The system uses two-way communication. The DCS cab sends digital signals to an MTH ProtoSound 3.0-equipped locomotive (ProtoSound is MTH’s trademark name for its combined decoder, speed-control, sound, and smoke components), and the engine responds. Place your locomotive on a powered section of track, scroll to the “add engine” menu, and data is exchanged between the controller and the locomotive. The locomotive then appears by name and road number on the roster within the DCS controller’s memory.

Another benefit of DCS is that software and the sound selections within MTH locomotives can be upgraded or changed using downloads available at MTH’s Web site.

Our DCS tests were conducted using a controller and command box designed for three-rail O gauge trains, available since 2002. MTH plans to offer the “DCS Commander” for HO use. This is an integrated DC power controller with 32 DCS functions at the press of a single button each. It will run DC and DCS engines in DCS mode, and it also has a “pass-through” mode for DCC users.

The instruction manual indicates this K4 model was designed to operate on up to 24 volts. Increasing the voltage produced speeds of 68.4 at 18 volts and 122 mph at 24 volts.

However, operating a passenger train on this high a voltage may burn out the 12- to 16-volt lamps commonly used for car interior lighting systems.

The K4’s drawbar pull with metal tires was equivalent to 10 free-rolling passenger cars on straight and level track. Substituting the driver set with traction tires increased the tractive effort to 45 passenger cars. However, under extreme loads, we found the traction tires gave the rear drivers so much traction that the front drivers lifted enough to derail on curves and the diverging side of turnouts.

Now that I have all of the test results, I’m left with mixed feelings about this locomotive. It’s a good-looking model with a well-designed and powerful mechanism and great special effects. If you use DCC on your layout, you’ll find it easy to operate. If you use DC power, check to make sure your power supply can handle its needs, and be aware that operating it at more than 16 volts may require you to make some changes to your other models.

Price: $399.95 with triple-mode control and sound system

Manufacturer

MTH Electric Trains

7020 Columbia Gateway Drive

Columbia, MD 21046-1532

www.mth-railking.com

Description

Die-cast metal and plastic ready-to-run steam locomotive

Road name

Pennsylvania RR

Amber light-emitting-diode head-light and backup light, reversing, with constant brightness and automatic dimming

Automatic triple-mode electronic control system that operates on DC, Digital Command Control (DCC), or MTH Electric Tarins’ Digital Control System (DCS)

Die-cast metal construction

Drawbar pull: 2.24 ounces, 10 free-rolling passenger cars on straight, level track; with traction tires, 10 ounces or 45 passenger cars

Engine and tender weight: 23 ounces (engine alone, 15 ounces)

Kadee scale-size, magnetic knuckle couplers (mounted at correct height)

Minimum radius: 18″

NMRA RP-25 contour nickel-silver wheels, painted black

Smoke and sound synchronized at 4 beats per driver revolution