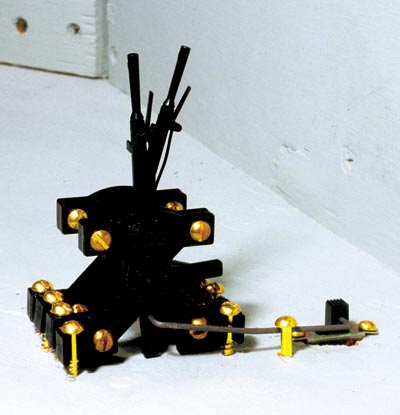

Each kit contains a sprue of molded lever parts, six-foot lengths of Teflon tubing containing a push-pull wire, plus the necessary hardware to connect each lever to a turnout, derail, or a semaphore signal. The actuating wire can be bent into a 1″ radius and still work, but I recommend using larger bends for better operation.

Three printed pages of illustrated instructions explain how to assemble the levers and eight different mounting methods.

I used a short length of .050″ piano wire to hook the lever to a single-pole double-throw (SPDT) slide switch that controls a slow-speed switch motor.

Each assembled lever is about 27/8″ tall (depending on how it’s mounted), 1/2″ wide, and 13/4″ deep. Nonworking latch-release handles are molded on each lever to match the prototype.

Assembly is an easy screwdriver job, and the spacers with two projecting flanges can be mounted in various ways. This system is neatly designed so the lever frames can be secured on or under a horizontal surface, or on a vertical surface.

With the current emphasis on modeling more of the jobs done by professional railroaders, this new product from Hump Yard is not only nicely done but very timely.