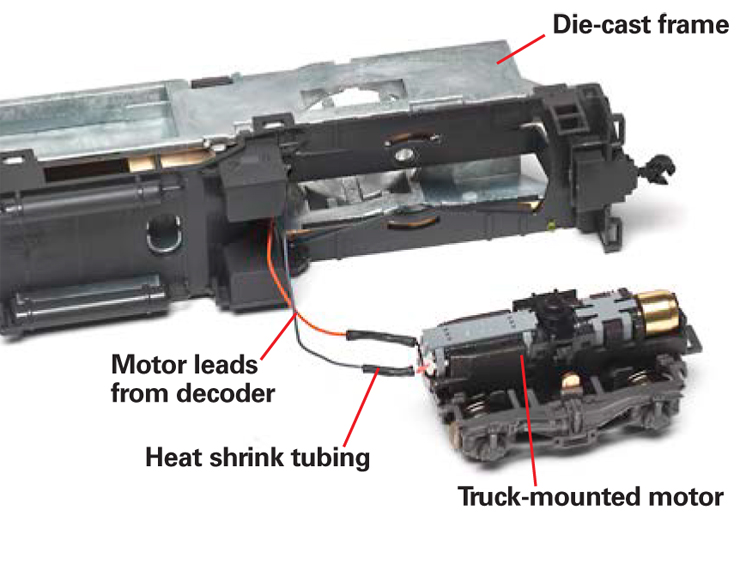

The Kato P42 features a unique design where each truck is equipped with a coreless motor. All the wheels on each truck pick up track power. Contacts on the truck sideframes touch contact strips under the metal frame. Two metal screws hold the factory light board in place and also act as power pickups for the board’s light-emitting diodes (LEDs)The motor leads are connected to thin metal strips that pick up track power from the wheels.

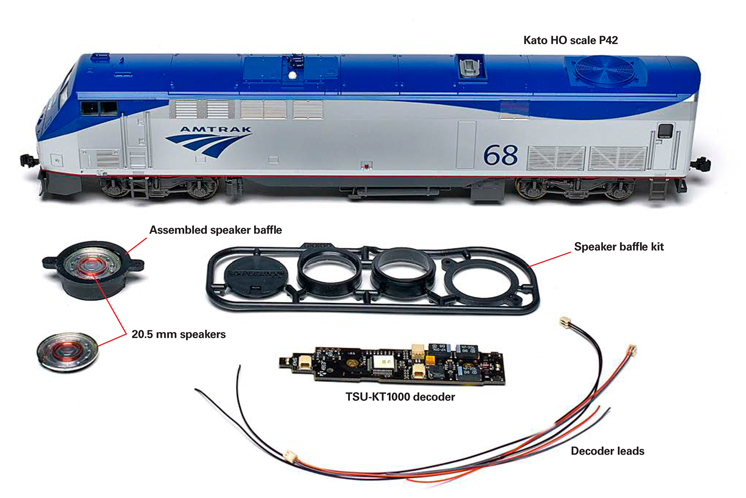

The SoundTraxx decoder replaces the Kato P42 factory light board. Surface mounted LEDs are included on the

decoder. The locomotive shell and trucks are press-fit and easy to remove. I appreciated that the only modification I had to make to the metal frame was to drill two 1⁄8″ holes for the decoder leads to run through to the trucks. Kato conveniently included starter holes in the P42 frame.

Instead, I suggest relying on only the solder to make the connection. First, I tinned the ends of both leads with solder. Then using locking tweezers I held the leads side by side as still as possible and quickly applied the soldering iron to make the joint. I finished the joint by covering it with heat-shrink tubing.

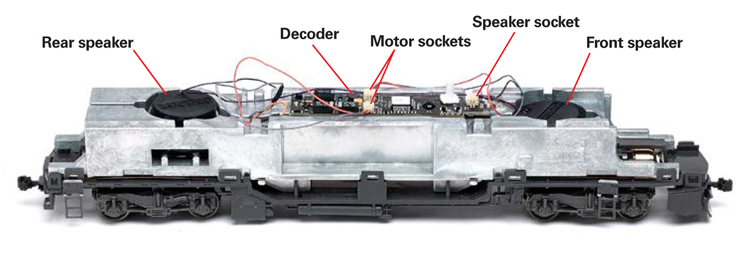

Following the included diagram, I wired the speakers in series and placed them in plastic speaker baffles. The

baffles are easy to assemble with plastic cement. Be sure to thread the speaker wires through the holes in the baffles before soldering the wires to the speakers. The enclosed speakers fit easily into the recesses of the locomotive frame.

I used the two screws from the original light board to mount the decoder to the frame. The board’s speaker socket should be toward the front. Finally I snapped the motor and speaker leads into their appropriate sockets. After confirming that everything worked with a quick trip down our test track, I slid the shell back onto the frame.

The model’s two motors ran smoothly in synch. The P42 hauled a full 10-car Empire Builder consist of Superliner cars. I easily programmed the decoder address to the locomotive number. The decoder supports advanced consisting, including the ability to trigger sound and lighting effects using the consist address. An extensive user manual with programming instructions is available at www.soundtraxx.com.

DCC sound. From the factory, the decoder isn’t set to full volume. I increased the overall volume using CV128. Even at full volume, the well-enclosed speakers didn’t rattle or buzz.

I especially appreciated that the SoundTraxx decoder allows independent volume control of each sound effect. For example, a modeler could lower the exhaust rpm volume and increase the air horn volume.

The rumble of the GE 7FDL16 diesel engine sounded like the locomotives I hear almost every day passing my home in Milwaukee. A modeler can set the decoder’s engine notching to increase according to a certain number of speed steps. The decoder also supports manual notching where the modeler can increase or decrease the engine rpm independently of the locomotive speed. I used the latter setting for our video of the P42 at www.ModelRailroader.com.

The decoder’s other user-controlled functions include a long and short horn blast, bell, dynamic brake fans, and

coupler clank. Functions can also be remapped, which is especially useful for those with throttles that support less than 12 function keys.

The decoder features 15 different prototypical airhorns. I set our sample’s airhorn to a five-chime Nathan M5 by changing CV 115 to a value of 10.

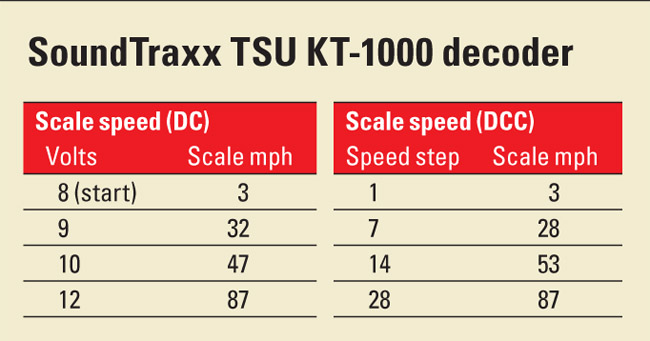

DC operation. Like most DCC decoders available today, the SoundTraxx Tsunami will operate on a direct-current (DC) layout. However, our review sample required almost 11V of track power before it started moving. To optimize DC performance requires that a modeler has access to a DCC system or a DC sound programmer such as the Model Rectifier Corp. Tech 6.

After I programmed the decoder’s analog starting voltage (CV63) to a value of 5, the decoder performed much better on our DC test track. Lights and sounds started at 7 volts and the model started moving at 8 volts. As you can see in the chart, it accelerated smoothly to a top speed of 87 mph.

Sound operation is limited to the diesel rpm, which increase as the locomotive accelerates. There are some automatic effects, such as the bell and a grade-crossing horn signal, that can be triggered by a DC power pack. However, activating these features requires programming CVs using a DCC system or DC sound controller.

Especially for DCC modelers, the SoundTraxx TSU-1000 sound decoder makes the Kato USA HO scale GE P42 sound as good as it looks.

Manufacturer

SoundTraxx

210 Rock Point Dr.

Durango, CO 81301

www.soundtraxx.com

Features

- 14, 28, or 128 speed steps

- 16-bit sound processor

- Board-mounted light-emitting diodes (LEDs)

- Built-in multi-band equalizer

- Designed specifically for Kato HO scale GE P42

- More than 14 sound effects

- Motor stall current: 1A

- Multiple airhorn selections

- Operates on Digital Command Control (DCC) and direct-current (DC) layouts

- Preset and user-loadable

- speed tables

- Supports advance consisting

- Supports service mode

- programming and programming on the main