Johnstown America dubbed its bi-level auto racks Aluminum Vehicle Carriers, or AVCs. The full-size cars are 17 percent lighter than similar cars of steel construction and they have a 50-year interchange life (40 is typical for free interchange without rebuilding or receiving extended service status). The bi-level cars are versatile, able to handle cars, pickups, vans, and sport utility vehicles.

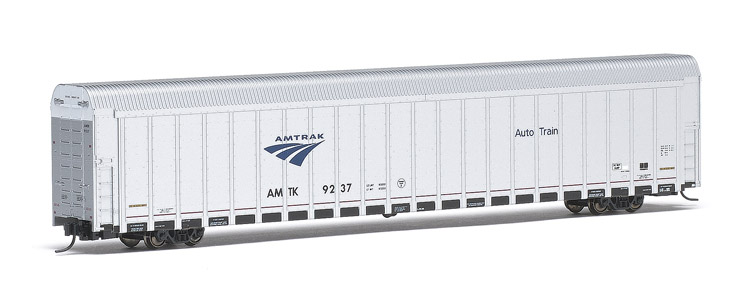

Canadian National purchased a 200-car lot of AVCs that were built between June and September 2004; Canadian Pacific ordered 375 cars between September and December of the same year; and Amtrak had 80 cars constructed for its Auto Train in 2005.

The Kato model has a one-piece injection-molded plastic rack system with a separate underbody. Grab irons, door hinges, defect card holders, and Automatic Equipment Identification tags, among other molded details on the rack, are well defined. There are differences in the rivet pattern on each side of the rack, which Kato accurately re-created.

The CN and CP cars use the same rack, but have finely printed dots to replicate the perforations on the panels. This is clever and convincing way of capturing that detail. Well done, Kato!

The underbody features a basic level of detail. The center sills, crossties, crossbearers, air reservoir, brake cylinder, hand brake lever, and cylinder lever are all molded. A light gray plastic “floor” snaps over tabs on the underbody to hold a metal weight in place. The car weighs 1.1 ounces, which is 0.4 ounce too light based on National Model Railroad Association recommended practice 20.1.

The pin-mounted injection-molded plastic trucks have correctly gauged metal wheelsets mounted on plastic

axles. Brass contacts on the inside of the each sideframe allow users to add an illuminated flashing rear end device or other end-of-train lights. The truck-mounted couplers have coil centering springs and are at the proper height.

All of the lettering on the sides and ends is legible under magnification. The placement of the herald, reporting marks, and car data matches prototype photos of car no. 9237 that I found online. The model’s dimensions match dimensional data on the FreightCar America website.

Careful attention to detail and accurate painting and printing make Kato USA’s N scale Johnstown American

bi-level auto rack, er, Aluminum Vehicle Carrier, a stand-out model.

Manufacturer

Kato USA Inc.

100 Remington Rd.

Schaumburg, IL 60173

www.katousa.com

Era: 2004 to present

Road names: Amtrak (two four packs), Canadian National, and Canadian Pacific

Features

- All-wheel electrical pickup for adding Flashing Rear End Device or other end-of-train lights

- Couplers with modeler-

- installed trip pins, mounted

- at correct height

- Metal wheelsets on plastic axles, correctly gauged

- Weight: 1.1 ounces, 0.4 ounce too light based on National Model Railroad Association recommended practice 20.1