This model runs on Märklin’s three-rail AC system. A two-rail DC version is available from Trix.

The C-Sine system differs considerably from a conventional DC motor, whether or not that motor is equipped with a decoder. On a conventional DC motor, permanent magnets on the motor frame create two opposite magnetic fields. The brushes and commutator plates conduct electricity to an odd number of windings (usually five) on the armature. The magnetic fields attract or repel each winding as it’s energized, making the armature turn. You vary the rpm indirectly, by increasing or decreasing the voltage to the armature, and change the direction by reversing the polarity to the armature. On some decoder-equipped locomotives, the decoder measures voltage fed back into the system as the motor turns and uses that to adjust the power to the motor, keeping the locomotive’s speed steady.

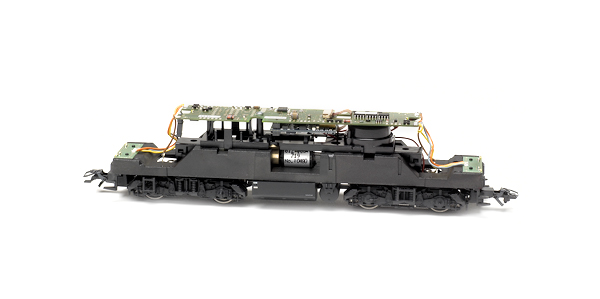

A C-Sine system motor is an inside-out version of a DC motor. This design eliminates two weaknesses of a conventional DC motor. In the C-Sine motor, the armature carries 12 skewed permanent magnets. The nine windings are fixed on the motor frame. Because no current goes to the armature, the motor needs no brushes or commutator, reducing friction and wear. (The Märklin motor also has ball bearings.) An electronic circuit energizes the windings with a sine-wave voltage, and the armature turns as the magnets on the armature are attracted to and repelled from the windings as the voltage rises and falls. The circuits vary the frequency of these sine waves to control speed and direction directly. Thus, when you set the locomotive’s speed, it maintains that speed irrespective of load.

Using a Märklin Digital system, the model had a starting speed of 1.5 scale mph and accelerated to a top speed of 140 scale mph. Throughout the entire speed range its current draw was only .02A.

I ran the locomotive up and down 4 percent grades on a 17″-radius curve and its speed never varied, even with a train. To really test its speed control ability, I resorted to pulling a steam switcher that had a metal boiler and one rubber tire-equipped axle. Then I varied the load on the class 218 by varying the power to the second locomotive, even cutting the power completely so that the class 218 had to drag the other locomotive. The class 218’s speed didn’t change until I ran the second locomotive in the opposite direction, and then the Märklin locomotive’s speed only dropped slightly!

The only negative I found was that the model stops abruptly if you cut the power instantly. That wouldn’t be a problem in normal operation because the decoder lets you set the acceleration and deceleration rates and the sliding shoe maintains reliable electrical contact with the track studs.

The new Softdrive Sine system in the Märklin class 218 impressed me more than any other locomotive drive I’ve tested. It can run slowly enough to serve as a switcher, pull a fast passenger express, and tackle a heavy freight, and it does so quietly enough that you can really enjoy the sound system. The Softdrive Sine system is already available in a variety of Märklin and Trix locomotives, and I look forward to seeing this type of drive in many other locomotives over the years to come.

Price: $415.00

Manufacturer

Märklin, Inc.

P.O. Box 510559

New Berlin, WI 53151-0559

www.marklin.com

Description: Three-rail AC HO

Märklin Digital locomotive

Brass axle bearings

Digital sound system

Directional light-emitting diode headlights

Drawbar pull: 10 oz. (equivalent to 140 HO scale cars on straight-and-level track)

Eight-wheel drive

Metal shell

Minimum radius: 14″

Operates on Märklin’s three-rail HO track

Separately applied detail parts

Softdrive Sine system

Truck-mounted NEM couplers

Weight: 16 ounces