The prototype. Between October 1963 and January 1966, General Motors Electro-Motive Division produced 1,250 GP35 diesel-electric locomotives for U.S. railroads. Part of the “second generation” of EMD diesel power, the GP35s replaced aging first-generation diesels, such as the GP7 and GP9.

The 2,500 hp GP35 was also the last EMD locomotive to use the 567 diesel engine. Although gone from most Class 1 railroads today (CSX has rebuilt some ex-B&O units into slugs), GP35s can still be found in service on short lines.

There were several external changes that took place during the GP35 production run; railfans refer to these changes as “phases.” The most notable spotting features for the different GP35 phases involve the thickness of the frame side sill and the number of latches on the engine-access doors.

The placement of latches on the engine doors and thick side sill on the MTH model are correct for a “phase 1b” GP35. All the details also match the prototype for our model, Southern Pacific no. 6580.

The body shell features sharply molded detail. Examples of the detail are well-defined caps on the fuel fill nozzles on each side features and the realistic safety tread on top of the walkways.

The handrails, uncoupling levers, and m.u. hoses are made of flexible acetal plastic to resist breaking. Other separate detail parts include etched-metal grills over the rooftop fans. There are also painted crew figures inside the cab.

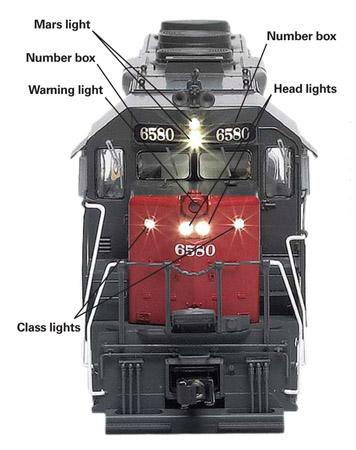

The model features prototype-specific details, including a rooftop bell and SP lighting configuration.

The plastic sideframes accurately model the correct 4-axle Blomberg trucks. Separate parts on the trucks include the brake cylinders as well as the speed recorder on the front fireman’s side truck.

The SP paint scheme on the model matches prototype photos. All the lettering is correct placed, including the white dot above the cab number, which indicates the unit is turbocharged.

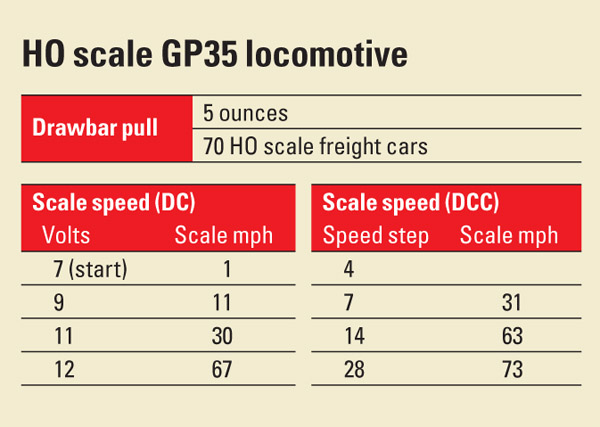

The model also ran smoothly during speed tests with an MRC Prodigy Advance DCC system and an MTH DCS system. When I set the DCC system to 128 speed steps, the GP35 moved at 1 scale mph in speed step 1. Using DCS, the model accelerated smoothly in 1 scale mph increments. In both DCC and DCS, the model reached a top speed of 73 scale mph.

The locomotive has impressive pulling power, enough to haul 70 HO cars on straight and level track. The Geep’s drawbar pull was also impressive during a hill-climbing run on our HO club layout, the Milwaukee, Racine & Troy. The MTH GP35 single-handedly pulled a 10-car train up a 3 percent grade without slipping or stalling.

During those tests, I set out and picked up cars. The Kadee-compatible remote-opening couplers operated with appropriate clanking sound effects when I pushed a button on my DCC throttle. (They also worked during my DCS tests). However, the coupler knuckle on the rear coupler inadvertently opened twice when starting out with a long train. This didn’t occur when I installed the non-remote-control magnetic knuckle couplers included with the model, so I appreciated that MTH included these couplers as an option.

The nose-mounted front warning light turns on only when the train is stopped when traveling in the reverse direction. On the prototype, this light would be turned on whenever the locomotive made an emergency stop.

The lighting effects are automatic, although there is some user control on DCC and DCS layouts. Function 0 turns on the directional headlights, while function 5 turns on all the other lighting effects. I think it would make for more prototypical operation if these features, including dimming the headlight, could also be controlled independently.

The model’s sound system credibly replicated the rumble of a 567 diesel engine during our DC, DCC, and DCS tests. On DC layouts the sound effects are automatic. There are more operating features available to those who run the model with a DCC or DCS system.

The GP35’s DCS decoder has many programmable configuration variables (CVs). This allows modelers to change the locomotive address, add momentum for acceleration and deceleration, and set up speed tables, and more.

The electronics also support CVs 19, 21, and 22 so that the GP35 can easily be programmed to operate as part of a multiple-unit consist. The free downloadable user’s manual available at www.mthhotrains.com includes a complete list of the programmable CVs.

For DCC and DCS layouts, the model features 28 user-triggered functions, including the horn, bell, and radio dialogue.

You can also manually notch the diesel engine rpm using functions 19 and 20. If you don’t have that many functions available on your throttle, don’t worry. All the functions can be remapped to different keys.

The ProtoSound 3.0 system is a highlight of the MTH locomotive. The HO GP35 accurately models its second-generation prototype, and its many sound effects make it a lot of fun.

Manufacturer

MTH Electric Trains

7020 Columbia Gateway Dr.

Columbia, MD 21046-1532

www.mthhotrains.com

Road names (three numbers each): Southern Pacific; Atchison, Topeka & Santa Fe; Baltimore & Ohio; Erie Lackawanna; New York Central; Norfolk & Western; Pennsylvania; Union Pacific

Era: 1963 to present

Features

- All-wheel drive and electrical pickup

- Digital Command System with ProtoSound 3.0 operates on DCS, direct-current (DC), and Digital Command Control (DCC) layouts (DCS version only)

- 8-pin DCC socket (DC version)

- 5-pole skew-wound flywheel-equipped motor

- Minimum radius: 18″

- Painted crew figures

- Remote-opening knuckle couplers at correct height (DCS version only)

- RP-25 contour metal wheels in gauge

- User-installed Kadee-compatible knuckle couplers

- Weight: 13.7 ounces