Next stop, Dyer Avenue! You can hear this announcement and more when you add MTH’s R17 New York City subway set to your layout. MTH has been building subway cars for the O gauge market for a while, but this is its first foray into HO scale subway cars. The R17 cars are equipped with the company’s Digital Command System. The model will also operate on Digital Command Control (DCC) and direct-current (DC) layouts.

New York City had three separate subway operators until 1940, when the city bought out the Interborough Rapid Transit Co. (IRT) and Brooklyn-Manhattan Transit Corp. (BMT) and combined them with the city-owned-and-operated Independent Subway (IND).

When the three lines came under city control, all new rolling stock was procured under a contract system denoted with the letter R. The R17 cars were delivered in 1955 and 1956 for use on the IRT lines.

Delivered in maroon paint, the cars were repainted in a blue and platinum mist scheme starting in 1970. In the early 1980s, the cars were painted plain white. Some of these cars were painted a brighter red, called fox red, for use in a shuttle service between Grand Central Terminal and Times Square station.

Two cars have been preserved in operating condition, four more have been converted into work cars, and two may still survive out of service. The R17s (400 produced) were built by the St. Louis Car Co. and were retired by 1988.

Our samples were painted in the 1970s Metropolitan Transit Authority blue and platinum mist scheme. The set consists of one powered car and three non-powered cars. All prototype R17 subway cars were powered.

Most dimensions were within scale inches of drawings in New York Subways: an Illustrated History of New York City’s Transit Cars, by Gene Sansome (Johns Hopkins University Press, 2004).

The car width scales about 101⁄2″ too wide and the truck center-to-center spacing is nearly 3 scale feet too short. Also, the top of the car is about 111⁄2″ too high, and the car floor is about 6″ too high. The truck wheelbase is correct, and the wheels are an accurate 34″ diameter.

The models are equipped with scale size Kadee knuckle couplers. The prototype R17 cars used Westinghouse H2C couplers, which use a pin and socket connection. The models’ Type E couplers result in the coupled cars being about 3 scale feet apart from each other. The pantograph gates at the ends of the prototype cars touch to keep people on the platform from falling between the cars.

Paint on the cars was evenly applied with sharp color separations. All of the lettering is sharp and clearly printed. Most of the added detail parts are on the ends of the cars, including wire grab irons and plastic pantograph gates, blade antennas, horns, and safety chains.

The truck sideframes are one piece, with simplified third-rail pickup detail.

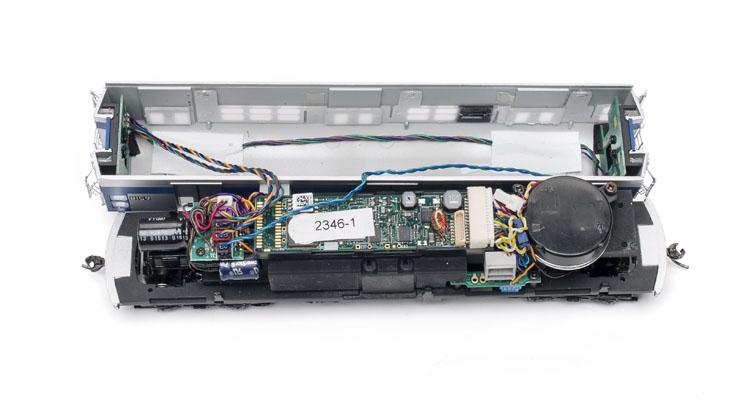

The mechanism of the power car has a center-mounted flywheel-equipped motor driving both trucks through plastic driveshafts. The frame is die-cast metal, and a die-cast metal weight is mounted above and around the motor and drivetrain. The MTH DCS circuit board is mounted to the weight above the motor, and a round speaker is mounted facing down above the rear truck. I spread the car sides to lift the mechanism out of the body.

Circuit boards attached to the insides of the car ends contain the surface-mounted light-emitting diodes (LEDs) for the headlights, rear marker lights, and express or local signs. Two more small circuit boards carry surface-mount LEDs to illuminate the route signs on the sides of the power car. The powered car has its windows frosted to conceal the mechanism and electronics.

The non-powered cars have die-cast metal floors and gray plastic interiors with seats along the sides and vertical passenger stanchions near the doors. The bodies were easy to remove, so it would be simple to add passengers. The cars appear to have the same circuit boards inside the ends as the powered cars, but the headlights and markers don’t operate. Two small circuit boards mounted to the roof manage power for LED lighting.

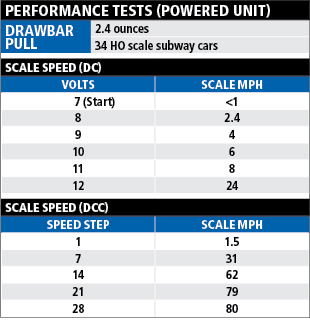

I started testing using DC power from a Model Rectifier Corp. Tech 4 power pack. Start-up sounds began at 6V, and the car started moving at 7V. In DC, all sounds are automatic, limited to the whine of the traction motors. A quick reduction in the throttle resulted in brake squeal as the car came to a stop. The headlights or rear markers on the power car light as appropriate for the direction of travel.

A nice feature in DC is the way you can flip the direction switch to slow the car to a stop, then start it back in the opposite direction without touching the throttle. I could also bring the car to a stop, change direction, then speed up again using the throttle without the sounds dropping out.

Since MTH designs its motors to operate on up to 24V, I could only reach a top speed of 24 scale mph at 12V, or 38 scale mph at 13V, the most our power pack outputs. Discussion on subway forums indicate the top practical speed in the subways is about 55 mph, but with the short distances, trains rarely get going that fast.

I next tested the model in DCC. Using an NCE Powercab, I was able to access all the functions on the decoder. This allowed me to turn lights on and off, change the train status indicator from Express to Local, sound the horn, set the “bell” (it’s actually more of a buzzer) and play station announcements. The car started moving at about 1.5 scale mph in speed step 1, and reached 80 scale mph at speed step 28.

One of the neat tricks of MTH’s control system is its ability to follow an operating sequence. I took the train to Model Railroader’s Beer Line project layout to test the system, stopping at grade crossings or outside businesses.

I followed the directions in the owner’s manual to set the sequence. Then I set the train into auto mode with function 7, and advanced the throttle.

The train announced the first stop, then started moving. A foot or so before the next stop, the train played a “next stop” announcement, then halted where I’d paused the train during programming. While the train was stopped, sound effects of people leaving and entering the train played, ending with a next stop announcement, and the train left.

The sequence repeated around the layout until it reached the starting point again, then after a short delay, the train started again. I kept it going until people came out of their offices asking me to turn down the volume. Function 6 allows users to set the master volume.

Individual effect volume levels can only be adjusted with a DCS throttle. With DCS, the power car could reach a top speed of 120 scale mph in 1 scale mph increments. Otherwise, the DCS and DCC operation was essentially the same.

With its light and sound features, this train could be the centerpiece of an urban layout. Since 40 percent of the subway runs above ground, these trains could be out in the open for all to see and enjoy.

Price: $379.95 with Proto-Sound 3.0; $279.95 without sound; two-car subway add-on set, non-powered, $119.95

Manufacturer

M.T.H. Electric Trains

7020 Columbia Gateway Drive

Columbia, MD 21046

www.mthhotrains.com

Paint schemes: All are Metropolitan Transportation Authority, blue and silver – southbound express, blue and silver – northbound express, maroon – southbound express, maroon – northbound express

Era: 1955 to 1982, depending on paint scheme

Features

▪▪Four-car consist with one powered car and three non-powered cars

▪▪Powered Car

▪▪Directionally controlled light-emitting diode (LED) headlight and marker lights

▪▪Five-pole, flywheel equipped, skew-wound, balanced motor

▪▪Kadee no. 158 scale whisker couplers, mounted at correct height

▪▪Digital Command System with Proto-Sound 3.0 operates on DCS, Digital Command Control, and direct-current layouts

▪▪RP-25 contour metal wheels, in gauge

▪▪Weight: 12.8 ounces

▪▪Non-powered cars

▪▪Detailed car interiors

▪▪Kadee no. 158 scale whisker couplers, mounted .020″ low

▪▪Metal chassis

▪▪Overhead LED interior lighting

▪▪Weight: 6.7 ounces