The prototype. General Electric hoped to build on the success of its four axle U25B with a six-axle version, the U25C. Both locomotives featured a 2,500 hp FDL-16 diesel engine. The two additional traction motors on the U25C provided more pulling power.

Only 113 U25C locomotives were built from September 1963 until December 1965. The first units went to Oro Dam Constructors, which hauled fill during the building of the Oroville Dam across the Feather River in California. Other U25C owners included Atlantic Coast Line; Chicago, Burlington & Quincy; Lake Superior & Ishpeming; Northern Pacific; and Pennsylvania RR. Following mergers, U25Cs wore Burlington Northern, Penn Central, Conrail, and Seaboard Coast Line liveries. Louisville & Nashville and the National Ry. of Mexico owned second-hand U25Cs.

In January 1966, GE introduced the 2,800 hp U28C, which looked identical to a late production U25C.

The model. The Rivarossi model’s dimensions match a builder’s diagram in the Simmons-Boardman 1966 Car and Locomotive Cyclopedia of American Practice. With the air reservoirs and screened access doors behind the cab, the model depicts what railfans refer to as a Phase IIIa U25C. Earlier phases had louvers instead of screens on the doors, and Phase I U25Cs had the air reservoirs at both ends of the fuel tank.

The Phase IIIa body is also correct for our review sample’s prototype, Northern Pacific no. 2515. The NP received two orders of U25Cs: nos. 2500 to 2514 in 1964 and nos. 2515 to 2529 in 1965.

Separate plastic parts include the snowplow, m.u. hoses, uncoupling levers, windshield wipers, and rear ladder.

There are see-through screens over the air reservoirs and radiator fans. The horn, bell behind the fireman’s side of the cab, and firecracker antenna are correct for the NP prototype.

Because the handrails and stanchions are single etched-stainless-steel assemblies, they have a square profile that isn’t prototypical. From normal operating distances I didn’t find this too noticeable. The metal parts are more resistant to bending or popping loose from the frame than the plastic versions I’ve seen on other models.

The plastic tri-mount truck sideframes are accurately detailed, including sand lines and separately applied brake cylinders. The separate speed recorder cables are truncated and not connected to the frame so the U25C can negotiate tight model railroad curves. The six-wheel trucks have the correct 7′-3″ and 5′-9″ axle spacing.

The striping and herald placement onthe model matches prototype photos. The edges of the steps and end handrails are correctly painted yellow. However, the cab numbers and Northern Pacific lettering aren’t the correct font. This is especially noticeable with the “2” in the cab number and the “E” in Northern across the long hood.

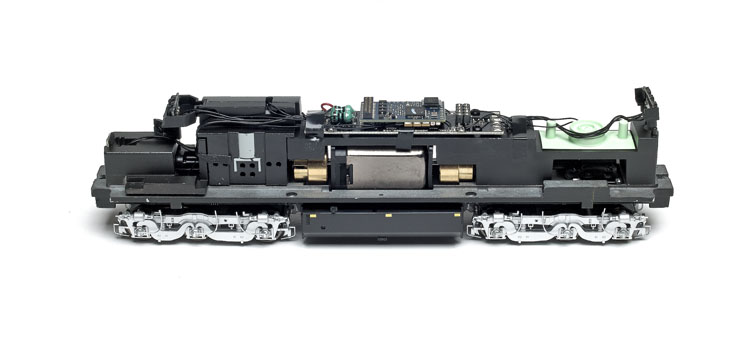

The can motor and flywheels rest on top of the die-cast metal frame. Additional metal weights surround the mechanism. Driveshafts connect the motor to gearboxes attached to each truck.

The main printed-circuit (PC) board is attached to the top of the weight. The PC board features 8-pin and 21-pin DCC sockets. Our DCC version included an ESU LokSound Select dual-mode sound decoder plugged into the 21-pin socket. A well-enclosed speaker is mounted above the front truck.

Surface-mount light-emitting diodes illuminate the headlights, signal light, and number boxes. The lighting and other leads are securely soldered to the main PC board.

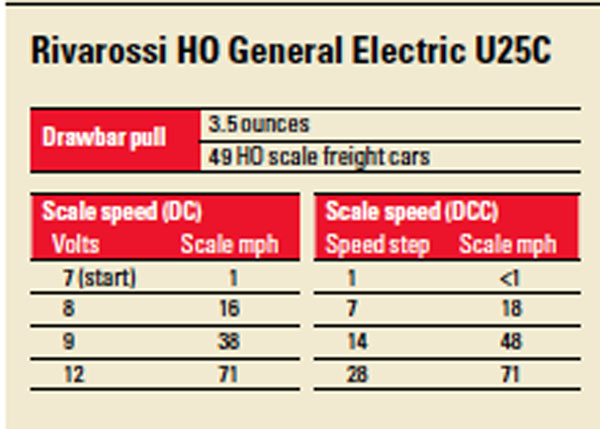

DCC performance. I ran the U25C on our DCC test track using a Model Rectifier Corp. Prodigy Advance2 system. Out of the box, the model rolled at less than 1 scale mph in speed step 1 and accelerated to a prototypical top speed of 71 scale mph. I was impressed by the realistic throttle response provide by the decoder. Just like on the prototype, I heard the engine rpm increase before the locomotive started moving.

The U25C looked and sounded even more realistic after I programmed configuration variables (CVs) 3 and 4 to add acceleration and deceleration momentum. With function buttons, the engine sounds can be manually notched where the rpm is increased or decreased independently of the throttle setting.

In addition to the prime mover, the decoder’s sound effects include the bell, horn, sanding valves, and coupler. Spitter valves can be triggered by function buttons or set to automatically sound when the engine shuts down.

Virtually every aspect of the ESU decoder can be customized. The volume levels of each sound effect is controlled independently. Custom speed tables can be set up. Every sound or lighting effect can be remapped to any available function key. Although a printed quick-start guide is included with the model, a more extensive user manual is available as a free download at www.esu.eu/en/start/.

The directional headlights, illuminated number boxes, and red emergency stop light are all controlled with separate function buttons. To be more prototypical, I remapped the headlights for manual, non-directional control.

The U25C was a lot of fun to operateduring “real-world” testing on the MR staff’s club layout, the Milwaukee, Racine, & Troy. The locomotive’s sounds and lights remained constant as the U25C rolled through crossovers and yard ladders. Its heavy frame and all-wheel drive provided enough power to pull 13 HO scale freight cars up a steep 3 percent grade without slipping or stalling. On straight and level track the U-boat has enough tractive effort to haul about 49 free-rolling HO freight cars.

DC performance. On our DC test track, the model’s lights and prime mover sounds started when I advanced the MRC Tech 7 power pack to 6 volts. At 7 volts the U25C crept along smoothly at 1 scale mph and accelerated to a top speed of 71 mph at 12 volts.

I was again impressed by the realistic throttle response, where the engine rpm would increase before the model started moving. As long as I kept the throttle at 6V or higher, the sounds stayed constant even when I flipped the power pack’s direction switch. In addition to the engine, the squealing brakes sounded when I quickly decreased the throttle.

Second generation diesel fans, especially those searching for U-boats, will want to check out the Rivarossi U25C.

$219.99 (DC, no sound)

Manufacturer

Rivarossi

Distributed by Hornby America

3900-C2 Industry Drive East

Fife, WA 98424

www.hornbyamerica.com

Era: 1963 to early 1980s

Road names: Northern Pacific;

Atlantic Coast Line; Chicago,

Burlington & Quincy; Pennsylvania

Features

All-wheel drive and electrical

pickup

Die-cast metal chassis

8-pin and 21-pin DCC sockets

ESU LokSound Select dual-mode sound decoder (DCC version only)

Five-pole can motor with dual brass flywheels

Metal RP-25 contour wheels in gauge

Minimum radius: 18″

Plastic knuckle couplers at correct height

Weight: 1 pound 4.2 ounces

I’ve just lucked into a pair each of ACL and L&N U25C units – 4 of the finest running locos that I’ve ever had the pleasure of owning. However, it appears that Hornsby/Rivarossi is abandoning the North American market and no longer offering non-European models.

Is this true?