North American Car Corp. built these PD3000 pressure differential covered hoppers from 1970 to 1985 primarily to haul dry cement. The models represent the cars with the smallest cubic capacity for heavy, dense loads, but NACC also had much larger versions for lightweight loads. The PD3000 model measures a scale 46′-4″ long, 10′-4″ wide, and 13′-11″ tall, which matches published prototype dimensions.

All were built to transport bulk, finely powdered products that had to be kept dry and free from contamination. Typical loads include bentonite clay, calcium carbonate, caustic soda, cement, fly ash, lime, limestone, plastic pellets, sugar, salt, sand, and talc.

Of course it wouldn’t be unusual to transfer a load either way between a PD3000 car and one or more similar pressure-discharge highway trailers.

The model is fabricated from a well-designed mixture of plastic castings, etched metal, and formed wire detail parts. The prototypes were built to customer order, so Spring Mills uses three different carbodies, three car ends, a pair of running boards, and additional details to produce its 22 versions. Thus the individual models have the correct corner posts, end panels, weld seams, wire grab irons, and car-pulling holes.

Our samples have Kadee couplers mounted in boxes that have their covers attached with small Phillips-head screws. I found the couplers drooped a bit, but a .010″ shim inside the box resolves this.

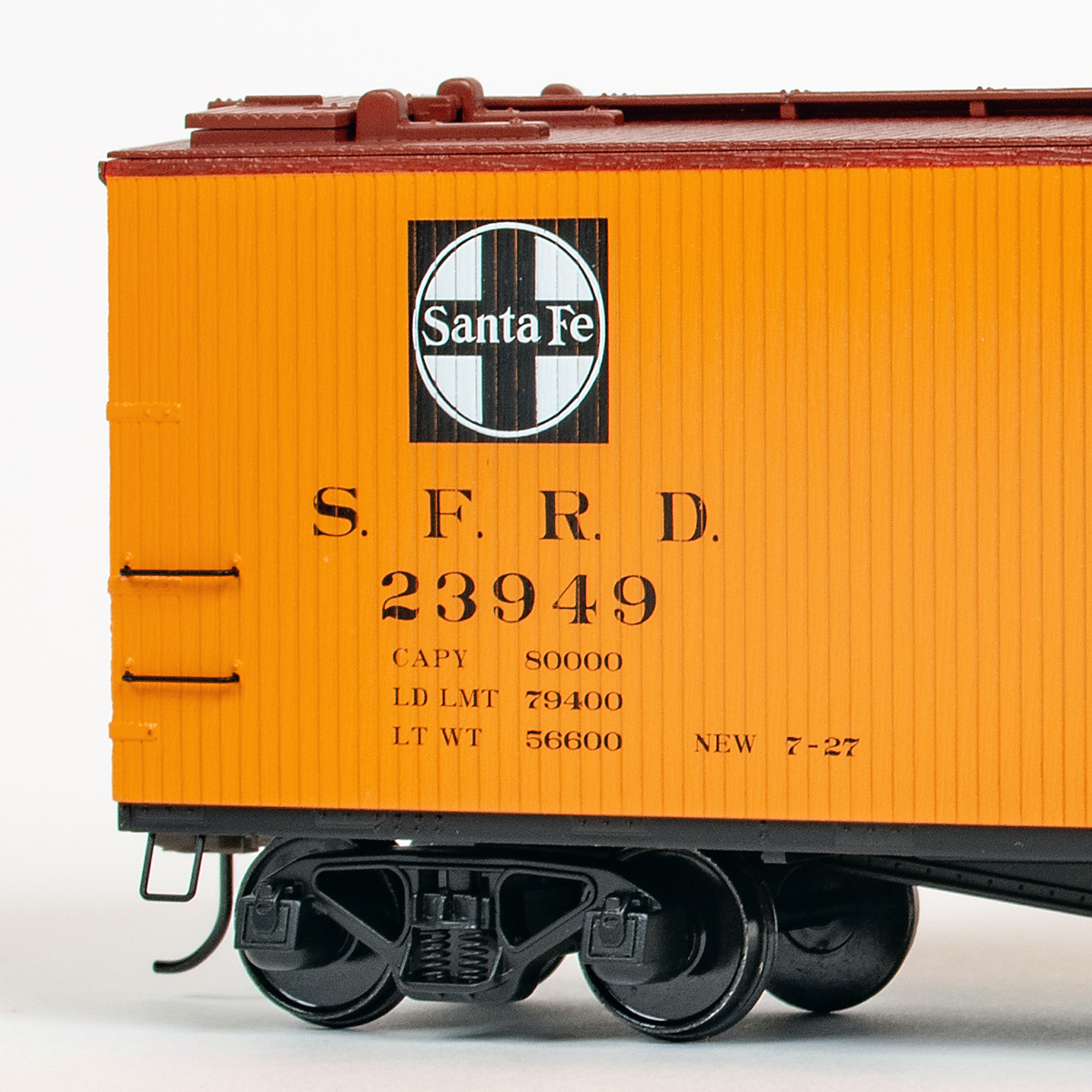

The cars came painted with a smooth, even coat of the appropriate color(s). All of the lettering was clearly printed and easily readable right down to the smallest data. Our samples that had colorful graphics were all printed in perfect register. Other models come with the realistic minimal lettering that’s found on many of the prototype cars.

I’m impressed with the accuracy that Spring Mills Depot put into these high-quality cars.

Manufacturer

Spring Mills Depot

P.O. Box 1616

Spring Mills, MD 21158

www.springmillsdepot.com

Era: 1970 to present

Road names: North American Car Co. (NAHX) demonstrator; NAHX (Roman, stencil, or block lettering) or oxide red; Fitrol Catalysts; IMCO Services; National Minerals Corp.; Atlas Cements; Blue Circle Cement; BJ Titan; Burlington Northern; CIT Group/Capital Finance; CEFX ex-NMC; First Union Rail; Halliburton Energy Services; Millpark Drilling Fluids; Boston & Maine; Penn Central Flexi-Flo; Conrail (ex-PC patch); Conrail Flexi-Flo (early or late versions); undecorated kits for phase 1a, 1b, 2, or 3 cars.

Features

- Accurate paint and lettering

- Etched-metal detail parts

- Four carbody phases detailed to match the 22 prototype paint schemes

- Free-rolling rigid-frame 100-ton roller bearing trucks

- Kadee metal couplers

- Weight: 4 ounces (matches NMRA Recommended Practice 20.1)