A newly tooled chop-nose GP9 has been added to the WalthersMainline. The four-axle HO scale road switcher is offered with or without dynamic brakes as appropriate and features drill starter points for grab irons and eye bolts and a ratchet-style handbrake (a detail kit is sold separately, no. 910-258).

The prototype. Our sample is painted as Milwaukee Road no. 970, one of 54 Electro-Motive Division (EMD) GP9s rebuilt by the railroad between June 1969 and October 1973. The rebuild included installing a non-turbocharged 645E diesel engine; refurbishing the frame; lowering the short hood; rebuilding the cab with a split windshield, new headlight, and number box housing; and reclassifying the locomotive a GP20.

Milwaukee’s GP20s shouldn’t be confused with stock EMD GP20s produced between November 1959 and April 1962. Those units had a turbocharger hatch on top of the long hood. The low short hood versions had a slanted hood.

Much to my surprise, GP20 no. 970 (now Georgia & Florida RR no. 5002) was photographed still in service in June 2019.

The model. The WalthersMainline GP9 features a four-piece injection-molded plastic body, consisting of the long hood, cab, short hood, and sill unit. The rolled-style handrails and formed-metal stanchions are molded in engineering plastic; the vertical handrails are painted white on our sample.

The model is based on what railfans refer to as a Phase II GP9, built between 1955 and October 1957. The model’s dimensions closely follow prototype drawings of a high short hood GP9 published in the April 1984 issue of Mainline Modeler magazine.

I compared our sample to photos of the full-size GP20 no. 970. The model should have split battery-box access doors with louvers under the cab on both sides, and the number box/headlight housing should have a flat top that tapers into the rounded cab. The model is also missing its rooftop air-intake housing (Milwaukee Road used different types, so refer to prototype photos). The first 78″ tall hood door behind the cab should be shorter to accommodate the housing. In fairness, mass-producing shop rebuilds is tricky, as there were often many variations.

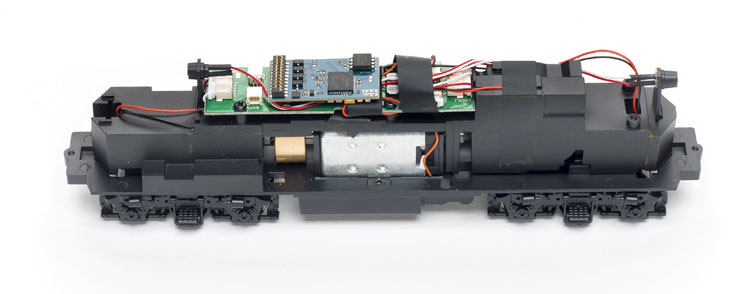

I separated the shell from the chassis by removing the draft-gear boxes, fuel tank, and two washer-head screws above the air tanks. A flywheel-equipped motor is seated in the center of the die-cast metal chassis. Secured by two screws, a metal weight spans the motor. The main printed-circuit (PC) board is screwed to the top of the weight, just above the motor. The Digital Command Control sound decoder sits atop the PC board.

On the test track. Our review sample is equipped with a dual-mode ESU Sound & DCC decoder, which features the same excellent sound quality but not all the features of the firm’s LokSound decoders. The various features are outlined in a brochure included with the model.

Adjustable features can be modified using configuration variables (CVs). These can be programmed via a DCC system or Java Model Railroad Interface (JMRI) software. The ESU LokProgrammer computer interface, sold separately, and the related free software don’t support ESU Sound & DCC decoders.

A list of supported programmable CVs is included in the model’s printed instruction sheet. Using our NCE PowerCab, I changed the locomotive address to the cab number and added acceleration/deceleration momentum.

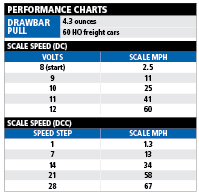

I again turned to our workshop PowerCab system for the locomotive’s DCC testing. At speed step 1, the locomotive crawled along at 1.3 scale mph. At speed step 28, the model reached a top speed of 67 scale mph.

The ESU decoder features typical user-activated effects. Pressing F0 activates the directional light-emitting-diode (LED) headlights. The bell and air horn are activated with F1 and F2, respectively. Diesel engine startup and shutdown are controlled with F8. Other effects include a coupler crash and compressor. The CN&W sample also includes a dynamic brake effect.

Function 9 triggers the Drive/Hold effect. When engaged, the Geep remains at the set speed. I then used the throttle knob to manually notch the engine rpm up or down. Pressing F9 again returns the speed to the throttle setting.

The model has a drawbar pull of 4.3 ounces, which is equivalent to 60 HO scale freight cars on straight and level track. I took the Geep to our staff layout, the Milwaukee, Racine & Troy, for further testing. The road switcher ran well, navigating the various turnouts and crossings without incident in both directions. The model was able to pull 10 50-foot boxcars up a winding 3 percent grade without stalling. The model’s back-electromotive-force control also kept its speed constant both ascending and descending the grade.

For DC testing I ran the model with a Bachmann power pack. The lights and sounds came on at 6.5V. The locomotive started moving smoothly at 2.5 scale mph at 8V and accelerated to a top speed of 60 scale mph at 12V.

Chop-nose GP9s continue to earn their keep on shortline and regional railroads and at various industries. As a fan of these units, I’m thrilled that Walthers has added this HO scale model to its Mainline product lineup.

Manufacturer

Wm. K. Walthers Inc.

5601 W. Florist Ave.

Milwaukee, WI 53218

www.walthers.com

Era: September 1972 to February 1985 (as decorated)

Road names: Milwaukee Road, Burlington Northern, Canadian Pacific, Chicago & North Western, Norfolk Southern, and Wisconsin & Southern. Four road numbers per scheme; also available undecorated (DC only).

Features

• Molded drill starter points for grab irons and lift rings (detail kit no. 910-258 sold separately)

• Proto-Max couplers, at correct height

• Ratchet-style handbrake

• Rolled-style handrails

• Weight: 13.2 ounces

• With or without dynamic brakes

Hopefully I will be building a GP9RM MASS COASTAL 2008 locomotive using the Walther’s Mainline Chop-nose GP9 chassis. I intend to use a MAPLE LEAF TRAINS GP9RM body. Give Maple Leaf a look. John, with the Prospect & Main RR in HO. Great blend of super quality products.