Modelers waiting for an HO scale Phase II GP35 have had their patience rewarded with the new locomotive model from WalthersProto.

Previous models of GP35s have all been variations of the Phase I locomotive, which represents more than three-quarters of production. But Walthers’ engine has the thin side sills of the final months of production, along with the correct inertial filter hatch cover and intakes, depending on the prototype.

The prototype. General Motors Electro-Motive Division built 1,333 GP35 locomotives between October 1963 and January 1966, 1,250 for U.S. railroads and the remaining 83 for Canadian and Mexican customers.

These locomotives were the last hurrah for the venerable 567 diesel engine, which produced 2,500 hp from 16 cylinders in the GP35. As second-generation diesels, many GP35s rode on traded-in trucks, either from earlier EMD products or Alco AAR Type B trucks.

Early locomotives, referred to as Phase I by railfans, had heavy sills shared with previous GP models. Starting in the summer of 1965, EMD began constructing the frame from sectioned I beams, resulting in a thinner sill. Phase II locomotives were further divided into three subgroups, called Phase IIa, IIb, and IIc.

The Phase IIa locomotives retained the flat inertial filter hatches of the Phase I locomotives. The inertial filter hatch is the roof panel just aft of the cab. Inside is the inertial filter, which provides clean air for the blowers that cool the electrical equipment, and for engine intake air.

While both Phase IIb and IIc had raised inertial filter hatches, the later Phase IIc locomotives introduced the corrugated inertial filter intakes seen on GP40 and later locomotives. The intakes for the filter are on the sides of the locomotive just below the hatch.

Many railroads had both Phase I and Phase II GP35s, but the Milwaukee Road; Richmond, Fredericksburg & Potomac; Rock Island; and Toledo, Peoria & Western purchased only Phase II GP35s. Rebuilt locomotives are still working for short lines and regionals today.

The model. Walthers’ new models all have thin side sills and raised inertial filter hatches, making them Phase IIb and IIc models. Dimensions match those on drawings of a Phase II GP35 in the October 1990 issue of Mainline Modeler.

I reviewed Walthers’ model of Milwaukee Road 1505, a Phase IIb locomotive with a raised inertial filter hatch and flat inertial intake grills. The model also has the correct MILW number boxes on the sides of the dynamic brake blister, and eight jacking pads – four at the standard locations centered over the trucks, then four more just inside the footwells. Other models have the standard four jacking pads, as appropriate.

Color separation between the orange and black paint is sharp, and all lettering, including the trust plates by the rear footwells, is legible. All handrails and grab irons are painted appropriately based on their positions.

The EMD Blomberg trucks on our sample feature separately applied spring hangers, brake cylinders, and a speed recorder on the front axle of the front truck on the fireman’s (left) side of the locomotive. See-through fan grills reveal painted fan blades, and the corner steps are perforated. The cab is equipped with seated engineer and fireman figures.

The GP35s are available as direct-current models or with dual-mode Tsunami Digital Command Control (DCC) decoders from SoundTraxx.

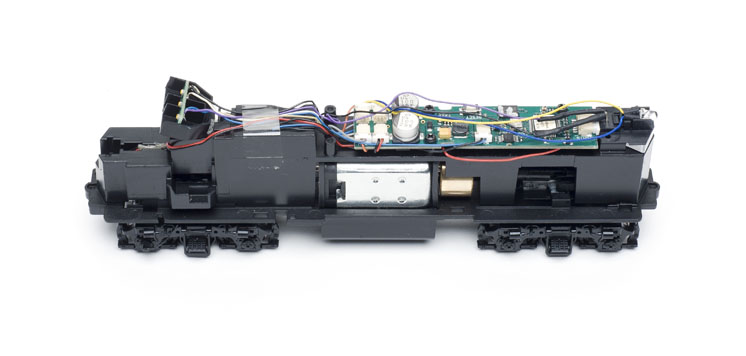

To lift off the shell, I removed the couplers, then the fuel tank. Under the fuel tank are two screws that must be removed before the shell can be lifted off.

Reassembling the model was a bit more difficult. The lights for the headlight and number boards fit into a shroud in the top of the locomotive cab. The lights and shroud won’t slide past the crew figures inside.

On our sample, the cab was glued to the rest of the shell. In order to get the lighting elements back into the top of the cab, I had to carefully separate the glued joints so the cab could be removed. With the cab off, it was a simple matter to reinstall the lighting elements.

[After I contacted Walthers about the issue, a rep suggested carefully spreading the cab sides slightly, removing material from the inner sides of the figures, or leaving the figures out of the cab to more easily re-install the shell. – Ed.]

Walthers’ Geep features a skew-wound can motor mounted in the center of a die-cast metal frame. Brass flywheels and driveshafts on both ends of the motor connect to gear towers on the plastic trucks, driving all four axles. All the metal wheels pick up track power.

A die-cast metal weight covers the motor and drive train and supports the decoder and speaker, if equipped, or the printed-circuit (PC) light board with DCC socket.

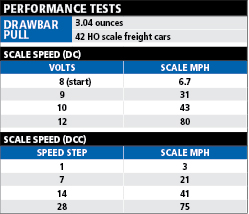

On the test track. The locomotive performed as expected for a dual-mode decoder-equipped model.

In DC, sound started steadily at 7V, and at 8V the engine began to move smoothly after two toots of the horn at a speed of 6.7 scale mph. Top speed at 12V DC was 80 scale mph. The bell rang until about 8.5V. The headlight was illuminated to match the direction of travel.

All sounds, such as start-up and the sound of the diesel engine revving as the speed of the locomotive increased, were automatic in DC. A quick boost to the throttle produced a grade-crossing signal, and a quick drop in the throttle resulted in brake-squeal sound effects.

In DCC, sound started when power was applied to the track. Engine sound notched up as I advanced the throttle, with the locomotive moving at 3 scale mph in speed step 1. In speed step 28, the locomotive reached a prototypical 75 scale mph top speed.

I easily advance-consisted the locomotive with a second GP35. Changing the address number to match the number on the cab and adding a bit of momentum to acceleration and deceleration were straightforward.

With the programming changes made, I took the locomotive to our Milwaukee, Racine & Troy staff layout. Using the locomotive brake feature of the SoundTraxx Tsunami decoder, function 9, it was enjoyable to bring a train into the Williams Bay yard, sort the cars, and deliver them to the industries along the backdrop. The locomotive had no trouble pushing and pulling cuts of cars through the yard ladders and no. 6 turnouts at the sidings.

With the outbound train assembled, the GP35 dug in and hauled 13 cars up the 3 percent grade heading out of Williams Bay.

Walthers has filled a niche that has long been open with this particular GP35. This smooth performer makes adding the later Phase II locomotive to layout rosters a much simpler task.

Facts & features

Price: $199.98, DC, no sound; $299.98, DCC and sound

Manufacturer

Wm. K. Walthers Inc.

5601 W. Florist Ave.

Milwaukee, WI 53218

www.walthers.com

Era: 1963 to present

Roadnames: Chicago, Milwaukee, St. Paul & Pacific (Milwaukee Road); Atchison, Topeka & Santa Fe; Burlington Northern; Chesapeake & Ohio; Chessie System; Chicago, Rock Island & Pacific; Conrail; Erie-Lackawanna; Gulf, Mobile & Ohio; Southern Pacific; and undecorated

Features

• Five-pole, skew-wound, high-torque, high-efficiency can motor

• Road-specific details

• Proto-Max metal knuckle couplers at correct height

• Turned metal wheels, in gauge

• Weight: 13.1 ounces