The Zimo system’s voltage is easily adjustable to operate trains in scales from N through G via a variety of tethered and wireless cabs that function in DCC or several computer-assisted modes.

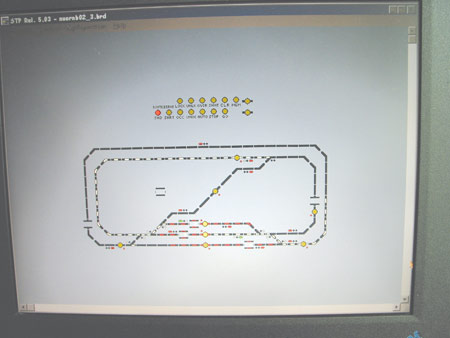

A separate computer option works with track section modules that provide detection functions to display a schematic track diagram. This displays train locations and the settings for a variety of other functions like turnouts and signals. Depending upon the system settings the trains can be operated under individual manual control, with an interlocked routing similar to centralized traffic control (CTC), or in a fully automated preprogrammed display mode.

The MX1 command station has built-in voltage and current metering with adjustable track output to deliver 12 to 24 volts to operate trains in all scales. With a separate 24-28VAC, 150-200W transformer (not included), it delivers a high current output – 8 amps from the base unit (or 16 amps if it’s combined with a booster unit). This is sufficient to operate 10 or more HO or 5 large scale locomotives.

The command station includes light-emitting diode (LED) indicators and liquid crystal display (LCD) readouts for its metering and other system information. Receptacles across the back connect the command station to the various other components.

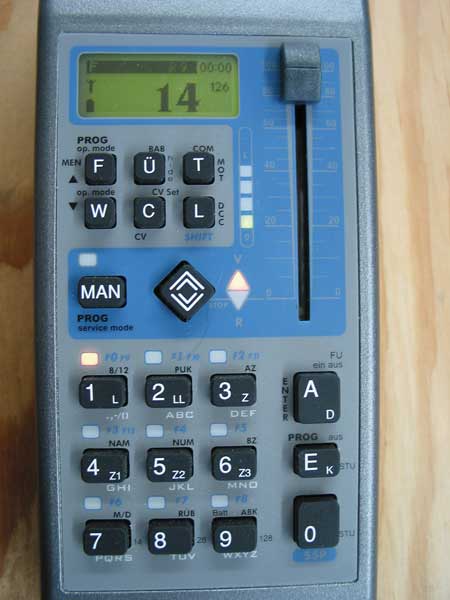

The MX2 cab is Zimo’s basic controller that operates trains and programs decoders, routing, and other automated functions. It has a three-color LCD for locomotive and accessory addresses, a sliding speed control, 20 keys for programming, and 16 bi-color LEDs to indicate function status and turnout positions. Each cab can handle up to 10,239 addresses, 800 routes, and numerous accessory items.

Other cabs are available with more graphic display and to operate using infrared and radio control links.

Zimo decoders offer noiseless motor control with 10,239 potential addresses and bidirectional communication. They include a choice of 14, 28, or 128 speed steps and have adjustable back electromotive force (EMF) sensing, output voltage, and variable speed tables. Function mapping is provided that goes beyond the NMRA recommendations.

A unique feature is that the locomotive decoders also acknowledge commands they’ve received. This talk-back feature allows these decoders to be programmed on the main track or on an isolated programming track.

- Track section modules control 16 block outputs for detection and automatic speed regulation to match signal indications.

- A speed limit module automatically applies speed limits to all trains to match signal indications in three different track sections.

- A reverse loop module automatically senses and reverses the track polarity when required for a moving train. This module is available in single- and three-location versions.

- An accessory module controls up to 16 paired or 32 individual functions to operate turnouts or trackside signals. Signals connected to Zimo accessory decoders and modules display gradual illumination and dimming.

- The turntable control module operates a table and aligns it with the selected track (up to 32 tracks may be used).

Sound interface. Zimo’s newer decoders include a Serial User Standard Interface (SUSI) which allows the use of an add-on sound unit with your own customized sounds. This interface (a small connector with four pins on the decoder) also adds control capability for up to 12 extra remote functions. This SUSI interface is supported by the NMRA and used by Zimo, Lenz, Dietz, and Uhlenbrock systems.

Software upgrades. Zimo’s MX21 cab, command station, and decoders can be upgraded with the latest software using a personal computer with a serial port, Internet access (for downloading the latest software), and the decoder update module MXDECUP. Most Zimo decoders sold in 2003 or 2004 can be adapted to handle the PC software, but need to have a one-time factory upgrade made at a nominal fee.

This part of the system requires an IBM-compatible PC with a 486 processor or better; Windows 95, 98, ME, NT 4, 2000, or XP operating system; and 16 to 64 MB RAM.

The software provides a user-defined flexible screen layout, mouse control, and the ability to “read” layout conditions and occupancy from the control modules.

On-screen display and programming of configuration variables (CVs), graphic speed tables, and other DCC features is included.

An advanced programming tool can be added to operate as a utility program from a user data base.

The “CAN-Bus” (Controller Access Network bus) is Zimo’s data link to handle communication between system components such as the command stations, cabs, modules for feedback information, and accessories. It works as a Local Area Network (LAN) so all system data transmission is done within one network.

Both sets use the MX21 cab to control locomotives, operate accessories, and for programming. Up to 10 locomotives can be connected in a consist on each cab by activating just one button.

A comprehensive instruction manual explains how all of these procedures are done.

System operation. We had no difficulty operating three or four trains under individual control at close intervals on a small (about 3 x 6-foot) N scale layout. The system’s three-color signal system looked great and functioned properly to protect the trains running on the various intersecting routes.

A laptop computer allowed us to try the system’s CTC style operation. In this mode, the schematic screen display looked similar to modern prototype dispatcher’s displays I’ve seen. Clicks of the computer mouse easily routed the moving trains through crossovers to pass each other as the traveled around the railroad while the signals continued to function.

In the automated display mode, a passenger train and a couple of freight trains followed individual preprogrammed routes around the layout. The computer kept track of the moving trains and adjusted their speeds to maintain separation between them. At the same time, the passenger train was occasionally routed through the depot where it slowed and stopped for passengers before continuing.

By the time we were done, I was really impressed with the capabilities of the Zimo DCC system. It is truly the most sophisticated control system I’ve ever seen, yet its starter sets, building block approach, and excellent documentation make it usable on advanced layouts of any size.

Prices: starter sets, $895 to $1,550; decoders, $32 to $137.50 (Note: prices may vary due to international exchange rates)

Manufacturer

Zimo Electronik

Schonbrunnser Strasse 188

A-1120 Austria

North American distributor:

Model Railroad Solutions

Zimo Agency of North America

1195 Velrose Drive

Kelowna, British Columbia

Canada, V1X 6R7

www.mrsonline.net

Features

Adjustable track voltage (12-24V)

Advanced design

Computerized control options

8-amp. power supply

LED indicators

Liquid crystal displays

Meets NMRA DCC standards

Metered track outputs

Multiple-function cabs

On-track programming

User can update system and

decoders via Internet

Wide variety of components

128 speed steps