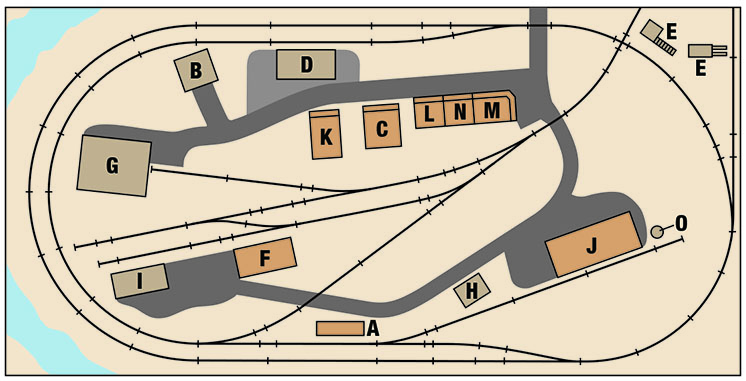

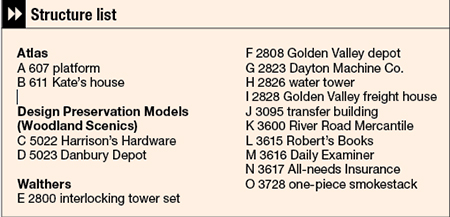

Model trains are a lot of fun, and having a layout to run them on is even better. However, trains and track in isolation don’t look very realistic. While the scenery we added to our HO Black River Junction project railroad in the March issue provided some visual interest, we need more scenic features before our layout will look like the world in miniature.

Making scenic details, especially structures and automobiles, can be a hobby all by itself; however, you can also purchase many of these models fully or partially assembled. Since we were building the Black River Junction in just five days, we chose to include some ready-made products to speed things along. Yet, even these needed detailing, and there were still plenty of kits to build too, so staff members not working directly on the layout were off-camera assembling kits and trees.

And that brings up a good point: Even if you haven’t started building your layout yet, there’s a lot of modeling you can do in the meantime. That way, once you do dig into layout construction, you have some detailed items ready to install.

In this, our final installment, Cody Grivno, Carl Swanson, Dana Kawala, and Tom Danneman will describe how they finished much of the scenery and added details to the layout.

We used a variety of injection-molded plastic structures on the layout, including a kit, snap-together buildings, and several factory-assembled models.

The transfer building was the only traditional (box full of parts) structure kit we used on the layout. After assembling the structure with liquid plastic cement, we airbrushed the building with Polly Scale Boxcar Red and painted the window mullions and freight doors Undercoat Light Gray.

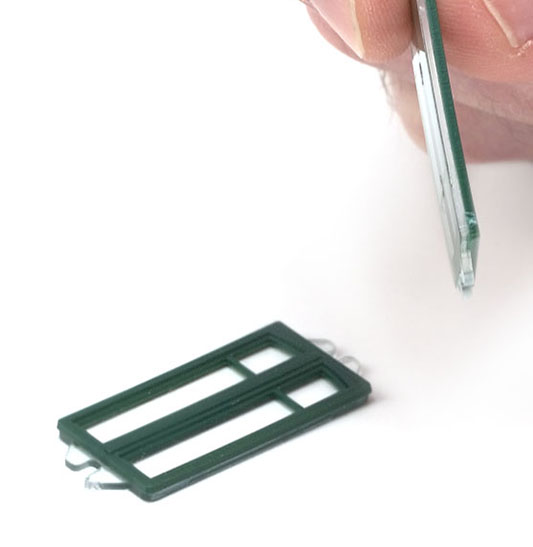

The snap-together buildings (Daily Examiner and River Road Mercantile, among others) are Gold Ribbon Series kits from Wm. K. Walthers, Inc. These structures feature interlocking tabs that make assembly, well, a snap. However, we brushed liquid plastic cement over the joints so the wall panels wouldn’t come apart. (We put the layout on display at train shows, so the buildings had to be durable.)

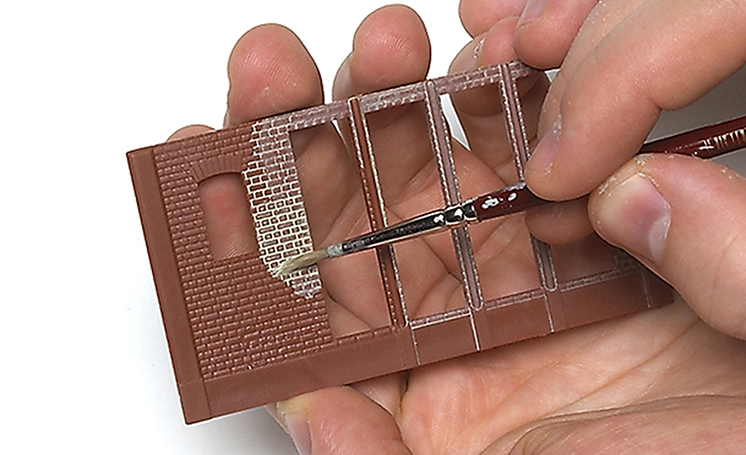

The Gold Ribbon kits also have parts with multi-color molding. For example, the windows have clear glazing with opaque mullions, which speeds up the assembly process.

We also used factory-assembled models, including the Golden Valley Depot and Freight House from Walthers and Harrison’s Hardware from Woodland Scenics. The Walthers structures are molded in typical building colors, while the Woodland Scenics models are factory painted.

Though most of the structures were molded or painted in appropriate colors, many were shiny, so the staff weathered them using a variety of techniques. Terry Thompson used thinned Polly Scale acrylic paints and an airbrush to weather the interlocking tower, transfer building, Danbury Depot, and others. I used thinned Polly Scale Aged Concrete (10 percent paint, 90 percent distilled water with a few drops of Liquitex flow enhancer added) to highlight the mortar lines on the Daily Examiner and All Needs Insurance. Erik Bergstrom sprayed the River Road Mercantile with Testor’s Dullcote, then weathered the building with powdered pastels.

As you can see, a variety of structures is available. You can easily add them to your layout in a short amount of time. – Cody Grivno

On one end of the layout we built a small farm field. For this project, I used a Busch no. 7182 plowed field mat. The mat is similar to corrugated cardboard and makes a convincing just-plowed field that could be used in most agricultural settings.

My first step was to determine the portion on the layout I wanted to cover with the field. Then, with a black felt tip marker, I scribed the mat with an outline of the field in relation to the track, road, and structures on the layout. I was careful to give enough clearance between the railroad right-of-way and the edge of the field since farm fields don’t go right up to the ballast on prototype railroads.

Next, I used a sharp hobby knife to cut the field out of the mat. I tested the fit and then glued the field to the layout with PL300 construction adhesive. Our mat was a little warped from being in the package, so, as shown in the photo, I pinned the field in place to keep it flat. Once the glue had dried I removed the pins.

The final step in building the field was to add the border details. I started by cementing Scenic Express Grass Paths along the edges, as well as some Woodland Scenics clump foliage. Where the farmer’s road enters the field, I made a gravel path with some Highball limestone ballast.

I also added some Central Valley no. 1601 fence sections to part of the field. For this, I drilled holes for the posts directly into the foam scenery and pressed the fence sections in place. No glue was needed. The last step was to add some figures and a tractor, and just like that, we had a farm field. – Tom Danneman

Though the Woodland Scenics vinyl grass mat looked fine, we wanted to give the scenery some additional texture. One technique I used was to apply static grass with a Noch GrasMaster.

First, I attached the alligator clip on the GrasMaster to a metal pin stuck in the scenery near where I was going to apply the grass. This serves to ground the work area.

Then I used a pipette to randomly apply matte medium on the hillside. With the cement still wet, I applied the static grass (I used Noch no. 7370 Wildgras). To ensure the fibers would stand upright, I held the GrasMaster about 1⁄4″ above the layout and gently shook the tool to dispense the static grass.

It’s important that you use only rayon-based static grass, otherwise, the fibers won’t receive the static charge they need to stand on end. Also, the GrasMaster converts battery power into 15,000VDC, so use this tool with care. – C.G.

There’s a lot to be said for taking the time to make your own trees. It’s fairly easy to get good results, it saves money, and you can vary each tree’s appearance.

That being said, there are also some darn nice ready-to-plant trees on the market. Most of the trees we used on the Black River Junction are 4″ and 6″ Scenic Express Ready-Made Trees. We also purchased one very large Noch Oak tree and two sizes of Faller Oaks.

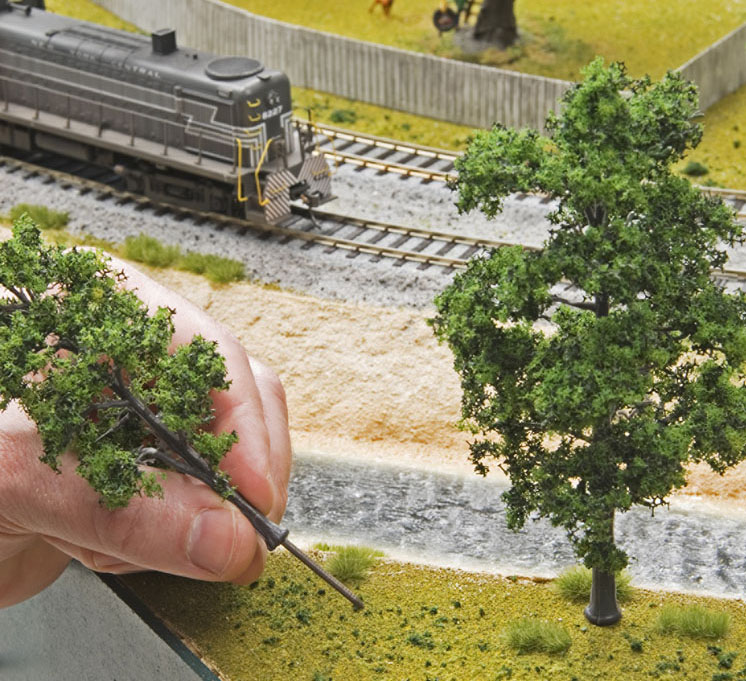

It was tempting to glue these trees in place and get on with the next project, but I like my trees to stay put once I plant them, so I took a moment to make a substantial connection between the tree and scenery base. The Scenic Express trees came with a thick, short plastic pin cast on the base. I nipped those off with sprue cutter. The Noch and Faller trees already have flat bases.

I then clamped several 1″ paneling nails points downward in the jaws of a vise and trimmed off the nail heads using a motor tool. Paneling nails are thin but made of hard steel, so I wore eye protection and did my cutting slowly and carefully, holding the tool so that the sparks would travel away from me. In the process, the nails became extremely hot. Looking back, I wish I’d let them cool a few minutes before opening the vise and letting the nails fall into the palm of my hand.

Next I used a .073″ drill bit to bore a roughly 3⁄8″-deep hole in the base of each trunk. I used a pin vise to drill the first hole, which worked fine but was a little too slow for my tastes. For the rest of the holes I used a variable-speed electric drill at its lowest setting, holding the tree trunks with pliers to make sure I didn’t drill my fingers.

I applied a big drop of thick gel CA (cyanoacrylate adhesive) to the end of the nails, placed the nails in the holes in the trunks. After we finished the basic scenery work, I planted the trees by simply stabbing the nail-equipped trunks through the ground cover and into the foam insulation scenery base.

As a finishing touch, I placed a pinch or two of ground cover material around the base of each tree and dribbled on a little diluted while glue to hold everything in place. – Carl Swanson

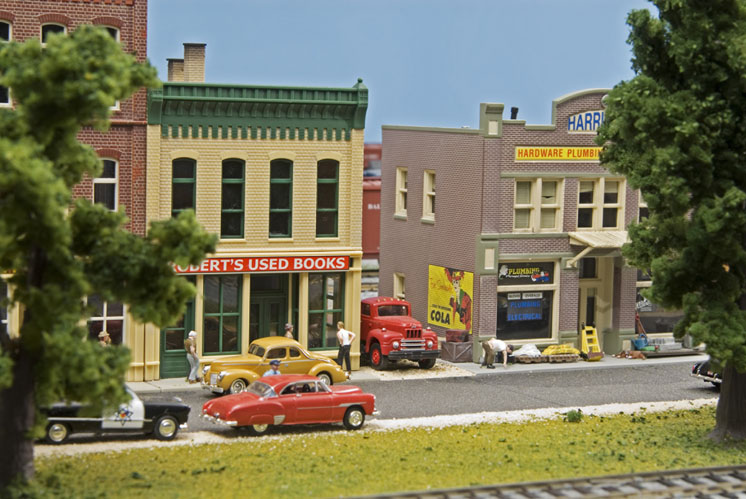

As with any step in the layout building process, a little planning goes a long way, and that includes adding figures, vehicles, and other scenic details. There’s a multitude of details available, so I first had to find those that fit the setting of the Black River Junction layout.

Figures should have clothing appropriate for both the era and the season of a layout’s setting. During the 1950s, the era represented on our layout, many men wore suits and hats around town. Also the Black River Junction is set in the summer, so you won’t see Santa Claus, ice skaters, townspeople in heavy overcoats, or anyone shoveling snow.

Just as in real life, all the vehicles I placed on the road had drivers in them. Unmanned cars and trucks stayed in parking lots or driveways.

Era-appropriate vehicles are important, but don’t try to make all your vehicles from the same decade. I used automobiles and trucks from the 1940s and 1950s. There’s always bound to be some older cars on the road, especially in a working-class town like ours.

Vintage advertising can also help date your layout. I built a wood billboard kit that advertises Nash automobiles, a nameplate that was phased out by American Motors at the end of 1957.

Once I’d found details to reinforce the Black River Junction’s setting, it was time to plan the scenes for each location. I laid out all the details on a board, grouping them according to where I thought they’d work best on the layout. I chose some figures to convey movement for each scene, such as workers unloading a crate at the freight house or a man stooping to pick up a coin on the sidewalk in front of the hardware store. I also added skids, garbage cans, and assorted junk to give industries a worked-in look.

Woodland Scenics products provide a good starting point for detailing a layout. Its Autoscenes figure and vehicle sets, such as the Lubeners loading up their sedan for a summer vacation, have nice detail.

I installed many of the details by hand but found a pair of Gentle Grips long-handled tweezers helpful for hard-to-reach areas. The tips of these tweezers are padded so they won’t damage the paint on the figures.

Before placing figures and other details, I gently sanded the surface that I’d be gluing to the scenery. This step is especially important for standing figures, since the bottoms of a figure’s feet might not be flat – otherwise you’ll eventually have sidewalks full of fallen pedestrians.

I used Scenic Accents cement for most of the figures. This adhesive remains tacky for hours, so I could reposition the figures if needed. For vehicles and other details, I used thick-viscosity CA, which gave me about 30 seconds of positioning time.

Figures and vehicles turned our empty streets into interesting scenes and added the final touches needed for a realistic layout. – Dana Kawala

How do we run the power to the turnouts? How do you wire the toggles etc.