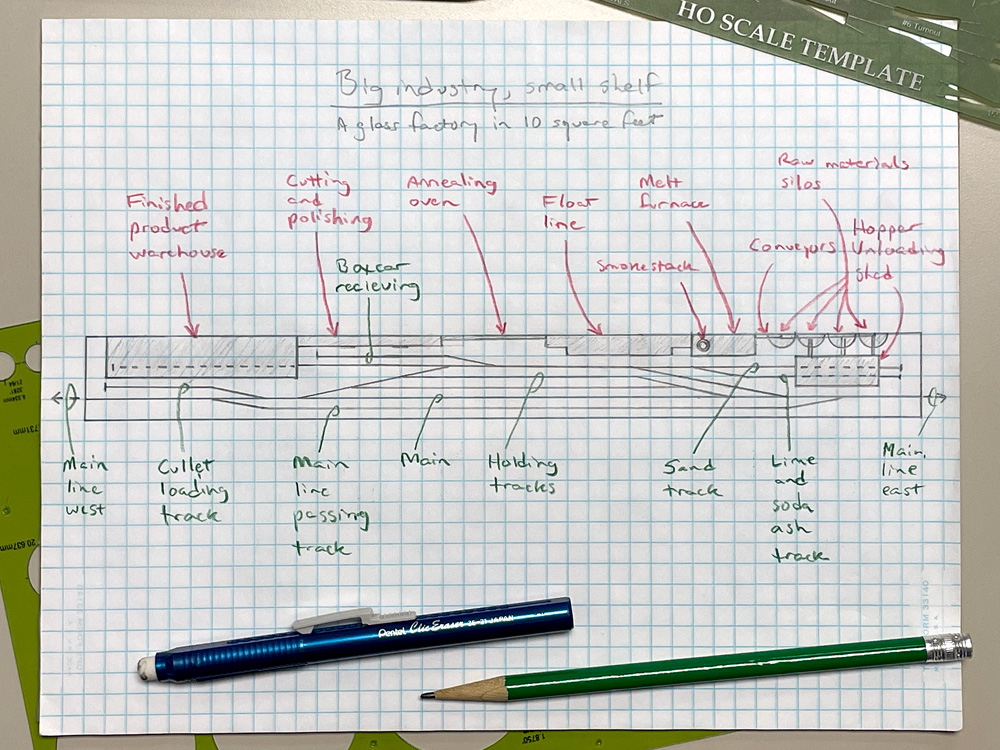

A reader’s inquiry to my “Ask MR” column (published earlier on Trains.com) inspired me to sketch a track plan for an HO scale glass factory shelf layout. We published a track plan for a glass factory in our January 2003 issue, but that was a 4 x 8-foot plan, and not everybody can devote 48 square feet to a single industry. But just because your layout is on a narrow shelf doesn’t mean you don’t have space for a big industry, and a plate-glass plant is an interesting but neglected modeling subject.

I’ve sketched two other single-industry track plans a while back for a paper mill and an ethanol plant. But those were larger and more structure-intensive. This plan for a glass factory shelf layout takes up much less space, but still offers a lot of operating potential.

As I described in my earlier article, glass factories melt together sand, powdered limestone, and soda ash to make glass. It’s a 24-hour operation that requires continual resupplying with raw ingredients. In a float-glass plant, the molten glass is poured onto a pool of molten tin, which is heavier than glass but has a lower melting point. This means the glass can float along on top of the perfectly smooth tin through the annealing plant as it cools to a solid. It’s then cut, polished, and packaged for shipment.

The raw materials must be kept uncontaminated, so they arrive in covered hoppers that are unloaded in a covered shed. My plan has two separate tracks, one for unloading sand and one for the other ingredients, increasing both operating interest and the number of cars that can be handled. These materials are stored in silos represented by half-cylinders positioned along the backdrop. The conveyors that move these materials from the shed to the silos and then to the furnace will make some visually interesting models.

The furnace, usually fueled by a natural gas pipeline, must run 24/7 to keep the glass from solidifying inside. This building is marked by a large smokestack. Next comes the float line, where the glass spreads out on the tin bath and starts to cool. The annealing oven heat-treats the glass to relieve internal stresses, so it doesn’t cool too fast and crack.

Materials used in the cutting and polishing house, such as felt, iron oxide, and salt cake, offer another opportunity for switching cars, boxcars this time. They have their own delivery track with two car spots. Packaging material like cardboard, wood, and excelsior (wood shreds) or Styrofoam (depending on the era) also arrives here in boxcars, as does the occasional shipment of maintenance and repair equipment.

Glass plants these days usually ship their finished materials in trucks or containers, but to boost this glass factory shelf layout’s operating interest, I decided the plant ships out by rail, as well. I extended a track inside the finished product warehouse for loading boxcars. Another spur alongside that warehouse is where empty gondolas are loaded with cullet, or broken glass, destined for a recycling plant. Since the factory workers are going to do their best to minimize broken product, only one gondola is filled at a time.

Switching this glass plant would likely be enough work to require a dedicated twice-daily train for the purpose, an AM Glass Job and a PM Glass Job. Two tracks are provided to allow the crew to break down their train to spot incoming cars where they are needed and to build an outgoing train of empties and finished product boxcars. There’s also a passing track so the locomotive doesn’t have to foul the main when performing runarounds. Even so, the entire plant probably needs to be treated as within yard limits.

If I allocated a little more width to this shelf, or if I was modeling in N scale, I would encircle the glass plant trackage with a chain-link fence and put the main line outside it so through trains wouldn’t have to slow down. I would also add a third holding track, separate unloading spurs for limestone and soda ash, and maybe a dedicated car spot for boxcars of packaging material. But I wanted to find out if a one-foot-wide glass factory shelf layout was practical, and I think I’ve shown it is.