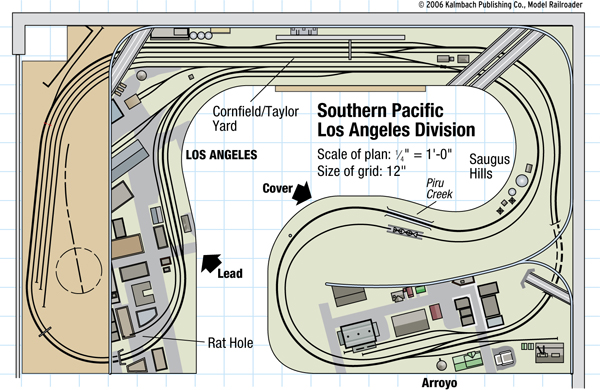

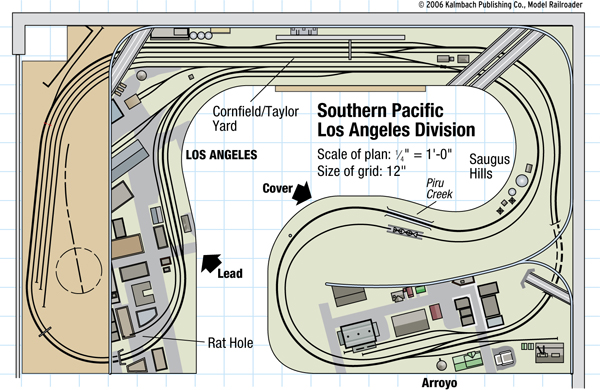

Track plan at a glance Name: Southern Pacific Los Angeles Division Scale: HO (1:87.1) Size: 12 x 19 feet Prototype: Southern Pacific Era: early 1950s Style: walkaround Mainline run: 85 feet Minimum radii: 33″ main line, 28″ sidings, 24″ industrial spurs Minimum turnouts: no. 6 main line, no. 5 sidings Maximum grade: none Originally appeared […]

Read More…

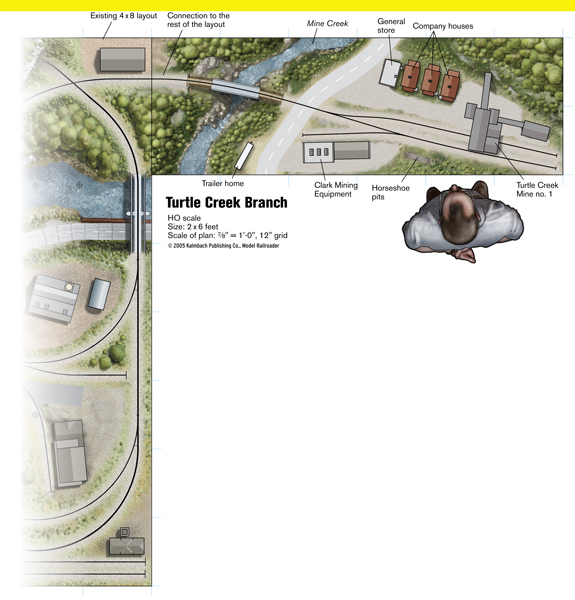

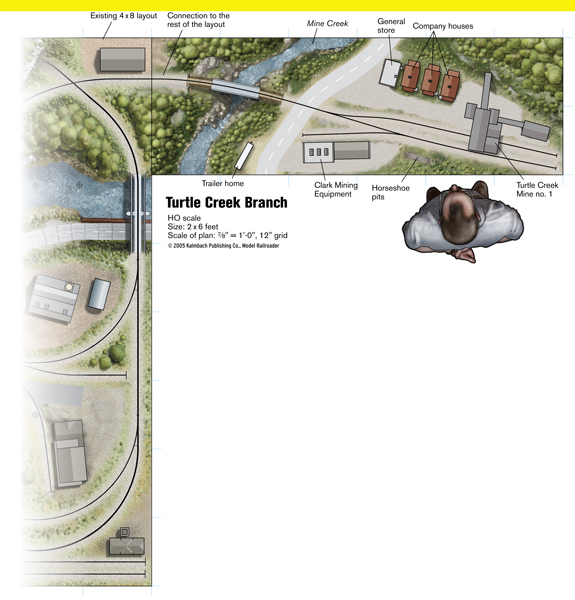

Track plan at a glance Name: Turtle Creek Branch Scale: HO Size: 2 x 6 feet Originally appeared in the January 2005 issue of Model Railroader. Click here to download a PDF of this track plan […]

Read More…

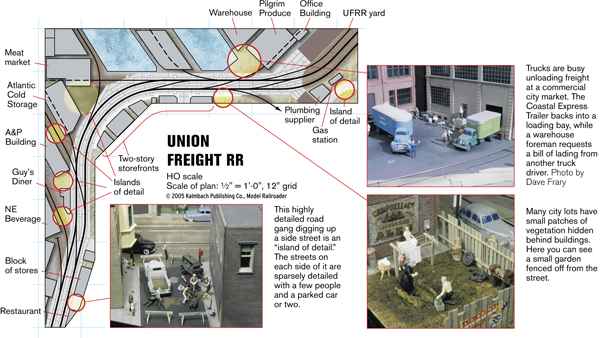

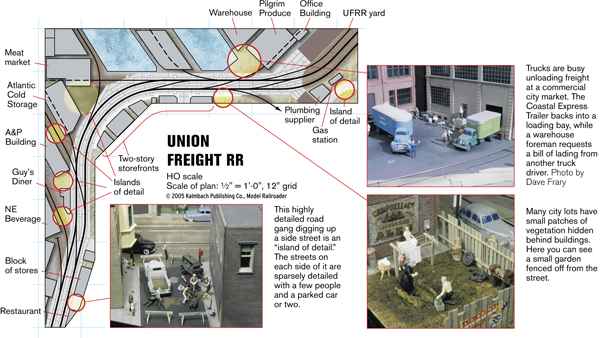

Track plan at a glance Name: Union Freight RR Scale: HO Originally appeared in the June 2005 issue of Model Railroader. Click here to download a PDF of this track plan […]

Read More…

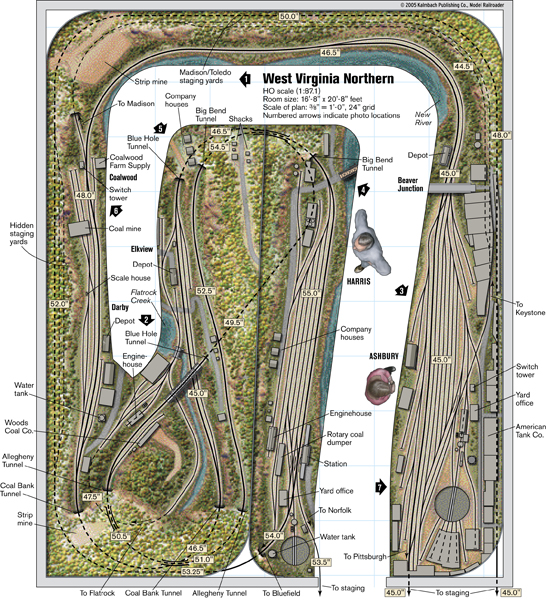

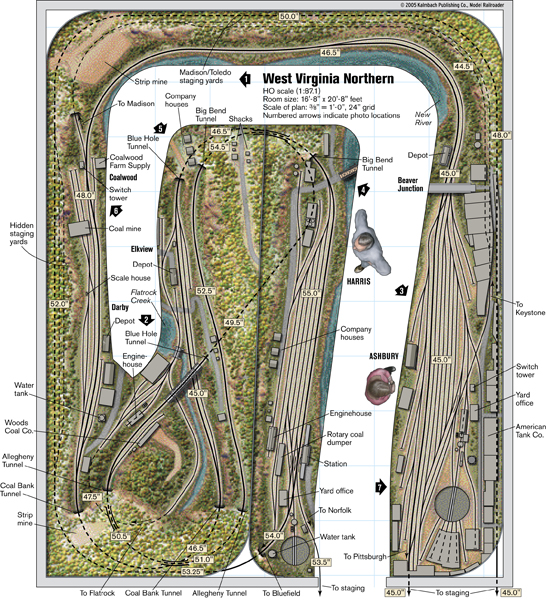

Track plan at a glance Name: West Virginia Northern Scale: HO (1:87.1) Size: 16′-8″ x 20’8″ with 11′-0″ x 2′-0″ and 4′-0″ x 11’0″ off-layout staging Theme: freelance, based on the Chesapeake & Ohio Ry. Period: summer 1952 Style: walkaround Mainline run: 126 feet Minimum radius: 30″ (main line) Minimum turnouts: no. 6 (main line), […]

Read More…

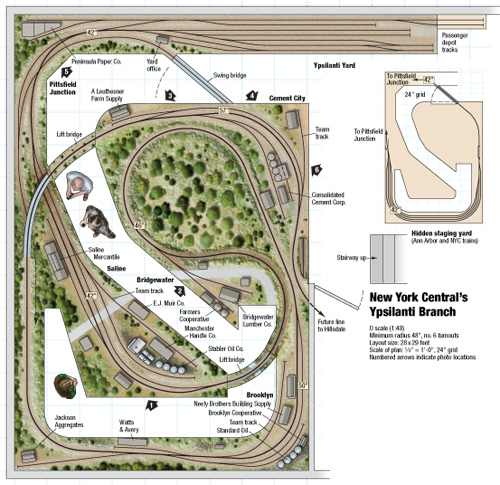

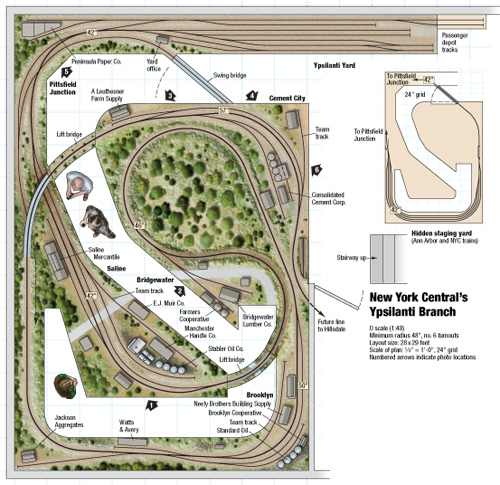

Track plan at a glance Name: New York Central Ypsilanti Branch Scale: O (1:48) Size: 26 x 28 feet Prototype: NYC branch line Era: 1950s Style: walk-in Mainline run: 144 feet Minimum radius: 48″ Minimum turnout: no. 6 Maximum grade: 2 percent Originally appeared in the May 2007 issue of Model Railroader. Click here to […]

Read More…

Q: You had a great tip about wiring a push-button switch to an old UCS track section, avoiding the original two-button controllers. Since I have an O-27 layout, I tried this with one of my No. 6019 tracks. When I attached the button switch between the number 2 wire and the transformer, the uncoupling magnet […]

Read More…

Q: I have a Lionel No. 364 conveyor belt log loader which was received as a gift in the 1940s or early 1950s. The red conveyor belt has disintegrated over time and I would like to know how to service the accessory to get it back into operation. Also, I would appreciate knowing the approximate […]

Read More…

Q: I am trying to familiarize myself with my postwar Lionel nos. 675, 2025, and 2035 locomotives by reading several of the Greenberg reference books. The more I read, the more confused I get. One book states that the no. 675 has Baldwin disc drivers. Another guide lists both disc and spoke drivers. One reference […]

Read More…

A cranky, old toy train locomotive with a terrible growl, a hot-running motor, and anemic power may be trying to tell you something. Before deciding to retire it, though, check the clearance in the armature brushplate bushing. A worn or defective bushing often results in one or more of these locomotive maladies. The solution is […]

Read More…

For better or worse, the wheels of O and large scale trains seem to attract more grease and grime than those of HO and N scale pieces. Perhaps it’s the size of the trains, perhaps the shape of the wheels, or perhaps it’s carbon that gets deposited during operation, but either way they get filthy […]

Read More…

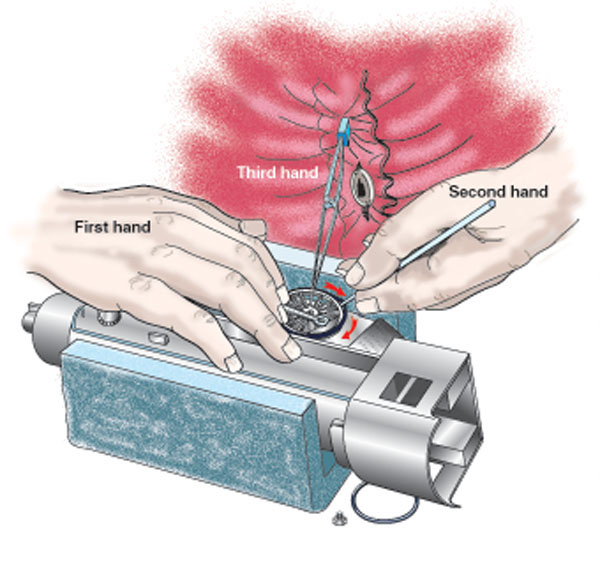

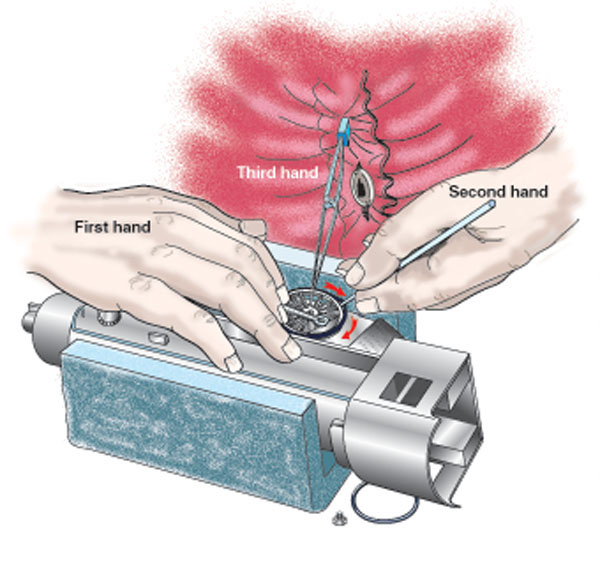

When it comes to replacing a broken traction tire on a steam locomotive, it helps to have a sense of humor. That and a third hand. I don’t have a third hand to lend you, but I can offer you the tips below to get a leg up on this friction-fraught task. Traction tires have […]

Read More…

Fig. 1: Pry off the original smoke unit cover with a screwdriver to gain access to the inside. Fig. 2: Remove the heater coil and smoke unit lining, both of which will be replaced in the conversion. Fig. 3: After scrapping and cleaning out all the pellet residue, make sure the air hole is not […]

Read More…