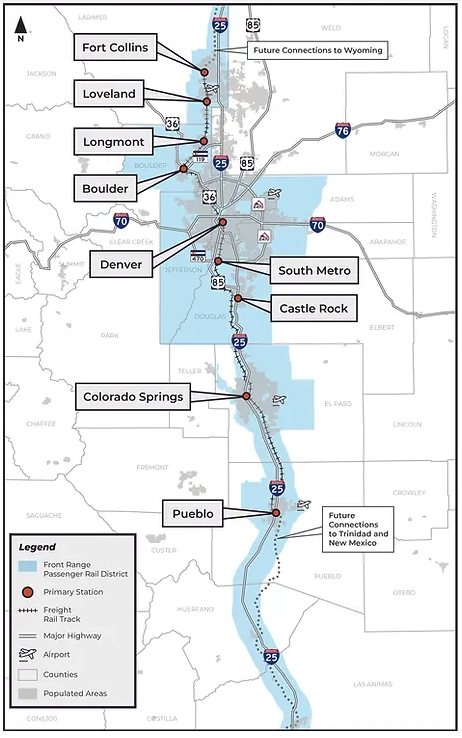

CHICAGO — The Acela 2 trainset which was due to arrive in Colorado today to begin high speed testing has no seats or interior furnishings — only concrete ballast designed to simulate various load factors. That trainset — the first of a 28-train order — left Alstom’s Hornell, N.Y., plant Monday for the Association of American Railroads’ Transportation Technology Center near Pueblo, Colo.

But Trains News Wire was able to get a first look inside the cab of power car 2100 when it paused for a media event Tuesday on Chicago Union Station’s track 2 before following the Southwest Chief out of town.

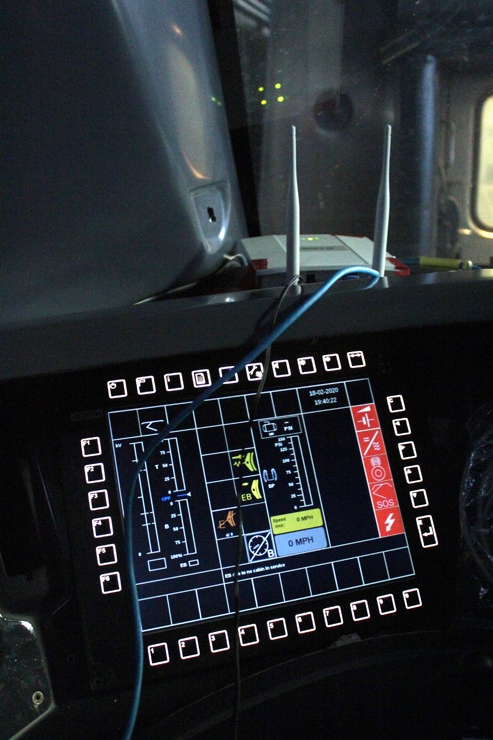

Alstom Train Manager Dave Meredith, who accompanied the equipment as it heads west, explains that sensors have been installed on every axle to make sure everything runs smoothly.

“We’re able to monitor the output of sensors to measure wheel slip,” he tells Trains News Wire. “If for some reason we have a locked axle, we’ll know it in real time and be able to safely stop the train. In addition, we have sensors that monitor train systems specifically for transport.”

Transmission of data is aided by an in-cab Wi-Fi setup that permits remote monitoring.

Head-end power was provided by the trailing Amtrak P42, coupled behind a Viewliner II baggage car as a buffer and heritage crew sleeper Pacific Bend.

Meredith says one of the main goals at Pueblo is to exhaustively test the trainset’s active tilt mechanism at various speeds on the electrified track’s elevated curves.

The Acela 2 is designed to operate at 6 to 9 inches of cant deficiency, “which is pretty substantial,” he notes. The track is designed with elevated curves as high as 6 inches, though most of the legacy Amtrak Northeast Corridor tracks the Acela 2 will use won’t allow it to reach the speeds of 160 mph at which it will be tested.

NH busier than LIRR?

I can only imagine the sweet scent of a brand new automobile inside the cab of the Acela II.

I do believe constant tension catenary is complete on the Metro North portion from New Rochelle to New Haven . I have no clue as to the section from New Rochelle to Harold Interlocking. But the problem on the MN section, many trains and many curves. The NH division of MN is the busiest commuter line in the country. Recently, I saw that CT was proposing eliminating some of the curvature through upgrades. How that would ever be accomplished is beyond imagination. Those of Westchester/Fairfield Counties are very wealthy NIMBYS.

CURTIS or ANYONE – What are conditions from east of Penn Station to New Haven? Is there also a need for upgrading there?

We’re getting older – the all-new constant tension catenary east of New Haven into Boston has now been in service twenty years! Seems like yesterday.

LAWRENCE – Thanks for the update.

Correct Mr. Sell, the catenary needs replacement (or upgrading?) for 160-mph operation, and Amtrak is working on that in NJ.

Correct me if I’m wrong, but I would think that the track is not so much the problem of operating trains at 160 in tangent areas; I would think that its the antiquated circa 1930’s catenary that has yet to be upgraded to constant tension.

As one who has been up and down the line through Ptn. Jnct. many times over the years since 1972, the need for massive upgrade spending is obvious. The wonder is that the operation is as good as it is. Give the Pennsy credit and Amtrak for making do.

On the segment of track in New Jersey that the catenary is being replaced is about 20 miles and straight as an arrow. It will cut about 4 minutes off the schedule. Wouldn’t it be great if they could eliminate some 60 to 90 mph speed restricted curves and make a big difference in running times.