The National Transportation Safety Board concluded Tuesday that the Talgo equipment’s lightweight design was a factor in the severity of the crash, near DuPont, Washington, on Dec. 18, 2017.

However, the NTSB has investigated Amtrak and commuter train overspeed derailments in recent years involving conventional passenger train equipment that resulted in multiple fatalities. Talgo said that its equipment is safe and performed as expected.

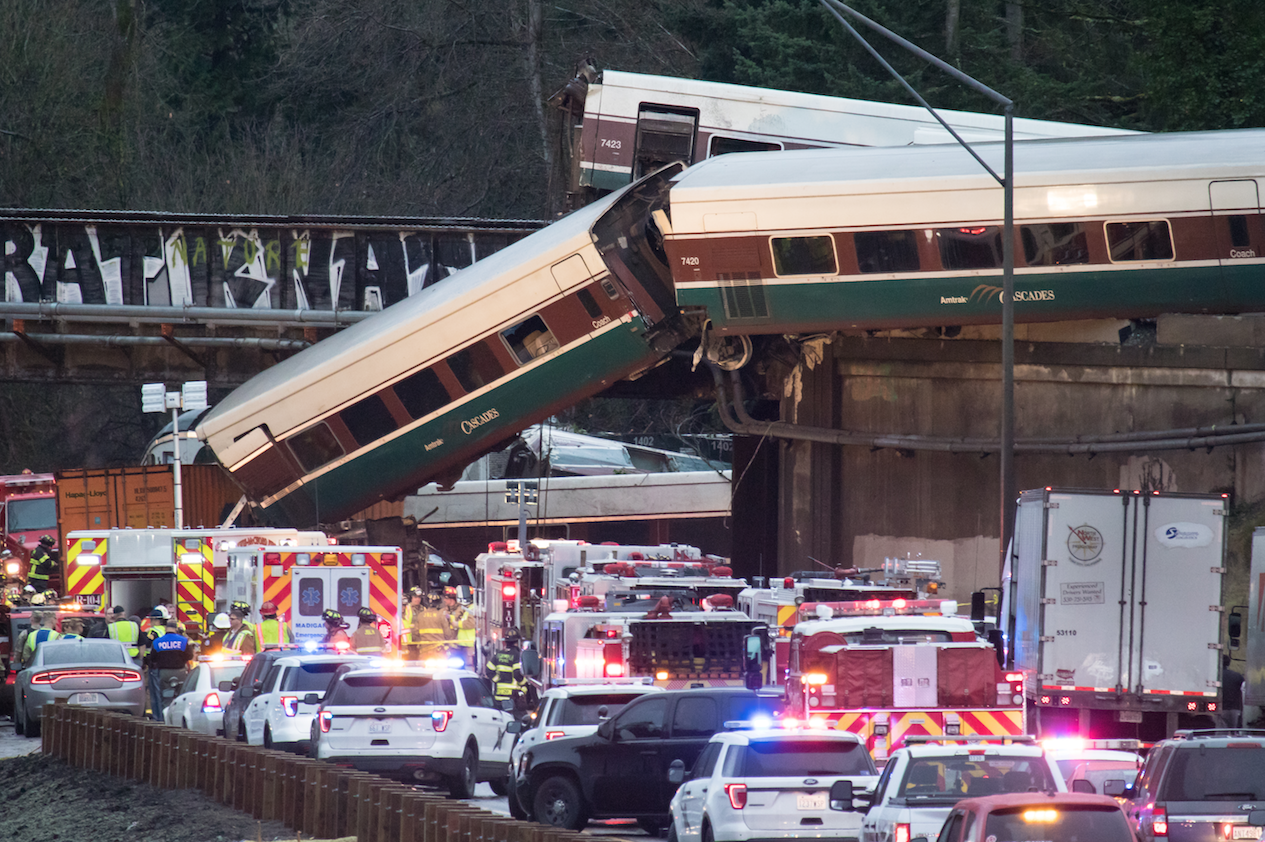

Three passengers were killed when Amtrak Train 501, a southbound Cascades train from Seattle to Portland, Ore., entered a 30-mph-curve at 78 mph, at Milepost 19.86 on the BNSF Railway Lakewood Subdivision, also known as the Point Defiance Bypass.

NTSB investigators found that the Spanish-designed Talgo’s wheelsets became detached from the train. Fifty-seven passengers were injured, as were eight people in vehicles on Interstate 5, where part of the train landed.

Investigators described them as “projectiles” that crushed passenger car compartments and highway vehicles.

NTSB, an independent agency that makes recommendations but has no enforcement power, found that the Talgo cars’ structure were inadequate for protecting passengers in high-speed crashes.

“Had the rolling assembly not detached,” Chairman Robert Sumwalt observed, “we may not have had fatal injuries.”

But was the NTSB too quick to find flaws in the Talgo design when other high-speed crashes it investigated involving conventional equipment also resulted in fatalities?

Take for instance the derailment of Amtrak Train 188 in North Philadelphia, Pa., in May 2015.

The train entered a 50-mph-curve at Frankford Junction, on the Northeast Corridor, at more than twice that speed. Eight passengers were killed when the train, consisting of conventional Amfleet cars, jumped the tracks and became entangled with a catenary support.

NTSB also probed the December 2013 derailment of a Metro-North commuter train in the Bronx. That train, consisting of conventional cars, derailed on a 30-mph-curve at 82 mph. Four passengers were killed in the crash.

The DuPont, Bronx, and North Philadelphia derailments were all overspeed events that could have been prevented with positive train control, the NTSB concluded.

In DuPont and North Philadelphia, the trains’ engineers lost positional awareness, in the former due to unfamiliarity with the route, and in the latter possibly due to distraction.

The Bronx engineer was found to have an undiagnosed case of severe obstructive sleep apnea, a sleeping disorder that can cause drowsiness and fatigue.

For its part, Talgo said its Cascades trainsets are safe, the DuPont derailment was not attributable to their design and that they performed as well or better than conventional rolling stock.

“The events surrounding the accident produced forces on Talgo equipment far different from and in excess of any for which any railroad passenger equipment is designed,” it said in a statement. “Our expert analysis led us to conclude that the behavior of the Talgo equipment was far better than what would have been expected of conventional equipment in similar circumstances.”

Why is no attention being given to the fact that the dead weight or the dead locomotive on the rear, literally kept shoving the light weight cars into a heap.? Without that weight, the Talgo cars probably would have remained linear. (or is this just too big a can or worms..?)

Typical Bureaucrats, they go after the Talgo’s safety design, that only failed, after the engineer crashed the train, by going over twice the speed limit at a curve designed for 30 mph. I also blame Amtrak for not providing adequate training to the engineer. The first couple of runs, should have been made in day-light, until the crew become very familiar with the route. Bureaucrats, just like to point fingers at their pet peeve, rather then address the real problem. It is like blaming the auto manufacture, for all those idiots that crash their cars, by driving too fast and ignore stop signs, traffic lights and road conditions.

Gerald

I may have agreed in the past that the public usually moved on after an aircraft (or train) equipment issue was fixed, I believe with all the instant communications and social media now available that we are in a new world of zero tolerance for mistakes and accidents. I am not saying I agree with it, but it seems to be bearing out. WSDOT has now announced that the Series 7 Telco sets will be taken out of service ‘as soon as possible’. Not sure what that means since I suspect Amtrak would be hard pressed to come up with that much spare equipment at a moment’s notice, but we will see.

Of course weight alone is not the perfect cure to safe design. I look forward to reading Talgo’s full-scale rebuttal, if they have one, of the NTSB Report. But I do not for a moment think equipment design played no roll in this or any other accident. But the traditional US crash standard, which required the car body to survive essentially 1,000,000 pounds pressure from impact over the draw bar was remarkably strong. By contrast the European standard assumed the vestibule area would compress and the body of the car survive.

In the DuPont tragedy the key to the degree of destruction suffered by the cars seems to have been their separation over the articulated trucks and the failure of their non traditional couplings, which were apparently at least partially some sort of cables.

One feature of US coupling standards is the use of tight lock couplers on mainline passenger equipment intended to operate at higher speeds. These are much less likely to break in a derailment. Train 501 might have better stayed in line if it had not broken apart as it went down the embankment.

A look at the aerial photos at DuPont shows that the train suffered multiple separations. The engine and the front cars went down the embankment in the direction of travel and to the right of the bridges. The fatalities took place in car 7504, which was demolished on that side as it descended. But other cars jumped the railing of the bridge and ended up on the highway to the left and at least one upside down. If the train had remained coupled there is at least a chance cars would not have stacked on each other, nor ended up upside down.

Of course bodies flying around inside would still have sustained severe injuries. But things would have been far more survivable if the detached wheel set had not effectively de-roofed car 7504 and if the side of the car body had remained intact. This does not generally happen to US standard cars.

We can take limited comfort from how many riders did survive the horrible progress of this accident. But we shouldn’t simply dismiss the NTSB’s warnings. And I say this again as someone who long argued US standards were too severe.

No design is perfect against an accident as severe as DuPont. But we need to think very carefully about what happened there and particularly consider its implications for future train-sets.

Are the new Avelia Liberty cars being built for 150mph + speeds on the NEC more likely to survive this sort of crash? They meet our newly revised standards. Should there be some reassessment of these in light of DuPont? Or is there no relevance to the Talgo 6 design and the new US standard? I don’t know the answer to any of this, but think the questions are worth posing.

Of course traditional US cars can be totally compromised in worse case crashes. This befell at least one Amfleet coach that got wrapped around a steel and concrete catenary mast in the Philadelphia NEC derailment. In the Silver Star South Carolina accident an Amfleet II lounge car was bent to a lazy “L” shape. But in that cornfield meet disaster the deaths were all in the Amtrak locomotive cab.

We have traditionally had the highest crash survival car standards in the world. Of course technology evolves, as do safety appliances like PTC.

The Washington tragedy was unambiguously the result of human errors. But we need to honestly assess what role the train’s cars played in the results that befell its riders.

Better training, PTC, better supervision, etc will all probably preclude another derailment at the DuPont curve, but the question of equipment integrity is a very fair issue to discuss and to try within reason to mitigate.

So many sources for this catastrophe. A few observations. I had actually discussed the 30mph curve with my friend Jim Hamre, who died in the crash. Jim had retired from the Washington DOT several years prior and was a highly experienced highway engineer. He explained that the Stimulus Funding that paid for the new route was not sufficient to cover what WashDOT projected could have been what he said could have reached a $60,000,000 total cost to realign not only the curve, but to also rebuild the two bridges over I 5 and to reconfigure the entire approach alignment from the north. Hideous irony? A cost that somehow should have been embraced?

Of course error by the engineer, lack of adequate pre-trip training, failure to have a train-master or other Amtrak supervisor in the cab, grossly excess speed, etc caused the crash. Fate is complex.

But we must not skirt around the catastrophic failure of the Talgo train-set. The wheel-set that essentially ripped asunder the car my friends Jim and Zach were riding in was part of an articulation between cars. It is horrifying to think that this flying truck could essentially de-roof and destroy the side-wall of a entire coach, thus sending the unfortunate riders in its path airborne out of the car to their traumatic fate.

I have long loved the comfort, sophistication, ride and style of the Talgo train-sets, but if the NTSB is right the time is now to retire the three remaining crash-standard wavered sets, and to add the never-used, stored, but fully US compliant Wisconsin sets to the two compliant sets in the northwest equipment pool, modified as needed to add Business Class seating and a nicer cafe.

This would give the Cascades Corridor four usable Talgo train-sets, against a need for five to cover current schedules with a reserve for servicing. Already one Seattle-Vancouver trip is run using a Superliner set. This reflects an existing shortfall of one Talgo set due to the repairs needed as a result of the much less severe derailment on the Point Defiance line, when an engineer overshot an actual derail on the approach to the Steilacoom draw bridge. The needed reserve could be met that way, or by allocating the back-up Amfleet set from southern California–or even Horizon fleet from the midwest.

More cars will be available fairly soon when the new Siemans fleet is delivered for midwest and California service–thus freeing up Amfleet/Horizon, even ex-NJ Transit upgraded cars. Not ideal, nor as stylish, but safer until Washington and Oregon can somehow find the funds to order new cars. If the current sets are to stay in service they must be strengthened/modified in some way to reduce the chance of anogther Dupont on the countless curves along the Cascades route.

The Talgo train sets were supposed to have pendulums to counterbalance centrifugal forces on curves. When this tragedy occurred, the lead locomotive that lacked pendulums left the track and pulled the train down with it. Clearly, pendulums can only do so much as attest the high speed train that overturned at excessive speeds on a curve in Spain early in this decade.

Carl Fowler and David McKinlay,

FIrst off there’s absolutely nothing wrong with the wavered Talgo sets…as noted the forces of that accident are not something you can design or build for without making the cars excessively heavy and there were other over speed accidents that had fatalities with conventional equipment that did/does meet the FRA safety standards(which are ridiculous by the way).

Secondly, in regards the to the 737MAX, the flying public will forget all about the accidents soon enough and hop on board without batting an eyelash, just like they have after every other fatal accident whether that be a bus, train or aircraft…especially in light of the most recent news that a bird strike may have played a part in the Ethopian Air crash(why someone would fly that airline is beyond me, it’s been reported as poorly maintained amongst other things). Third, blame the pilots also for not knowing how to fly a modern fly-by-wire jet manually, had they known how to do that I’m sure both crashes would’ve been averted(unlike American pilots which have to be certified annually in manual flight, most foreign airlines rely on the auto-pilot feature for much of a planes flight, including landing and takeoff in some cases(mostly Asian carriers).

While I understand the comments below about retiring the non compliant Talgo sets if possible, I would submit that to the general public this will be perceived in much the same way the Boeing 737 MAX has been. The general public will be reluctant to ride on Talgo’s, and will mostly ignore those that point out that newer Talgo sets have better crash worthiness. Perhaps it’s time that WSDOT and ODOT (owners of the Talgo’s) make some inquiries about adding onto the current order of Siemen’s cars for California and Illinois, and phasing out the Talgo equipment.

I found this article for what it’s worth:

https://www.cbs58.com/news/former-talgo-engineer-reacts-to-seattle-train-derailment

I thought this line was pretty telling:

“I was stunned. They were designed to survive a collision like that.”

I am advised elsewhere that the Talgo set damaged at the Steilacoom draw bridge is back in service. This still does not change the reality that only four fully US crash compliant sets exist, if the Wisconsin units are brought to the Cascades route.