“The idea came about as we were looking for ways to grow our parts business,” Director, Parts Sales Levi Sweazy tells Trains News Wire. “Thousands of (cast) knuckles are replaced each year.” He notes that the low cost of cast parts left many railroads maintaining the status quo, instead of looking to innovate sooner.

Association of American Railroads requirements called for a static load test of 400,000 pounds and operating 600,000 cycles on a test rig. The company hopes to have full AAR approval by 2021-2022. In the meantime, with limited approval, the company will deploy 1,000 forged knuckles to both railroad and private owner customers in early 2020 for in-service testing.

While the cost is higher than the traditional product, the company sees an overall savings for the industry. “We think that both railroads and shippers will see benefits in fewer replacements and in-service failures,” Sweazy says.

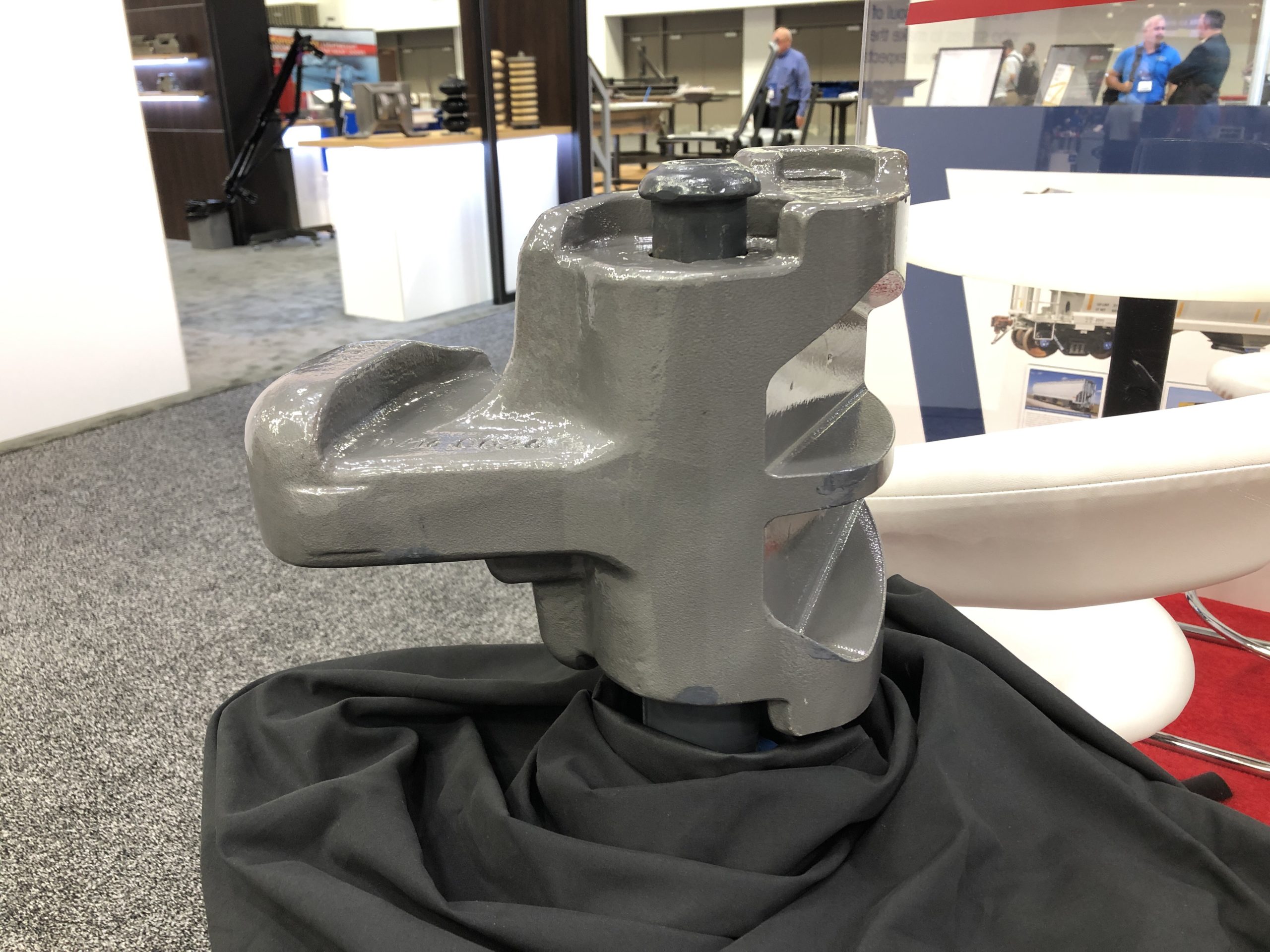

I did a quick search for Freight Car America Forged Knuckle and was linked to a new release on Railway Age’s website. The knuckle weighs the same a cast knuckle. Look at the photo and you can see that it has matching face surfaces but the body itself has external void space with a reinforcing rib. In regards to Mark’s question AAR specification require the strength of the knuckle to be less that the coupler body so that it remains the “week link” that is easiest to replace.

I suspect that what is driving this is that it can be made more reliable than a cast knuckle which can have hidden void space defects that can cause failures. I know from my RR Mechanical days, one of the first questions after a knuckle failure was what percentage was a new break verses an old break.

Same thing I thought W,when I first saw the word forged. Bound to be heavy.

How much does it weigh? Cast knuckles have empty space within the hand and that reduces weight. Wonder if any of designer ever worked freight trains and had to carry a knuckle, or lift to install one? More cost, more weight, I don’t see they are entitled to any of the replacement market.

How many knuckles are replaced because of wear rather than breaking? Will a stronger knuckle lead to failures of more expensive and harder to replace draw heads and draft gear?