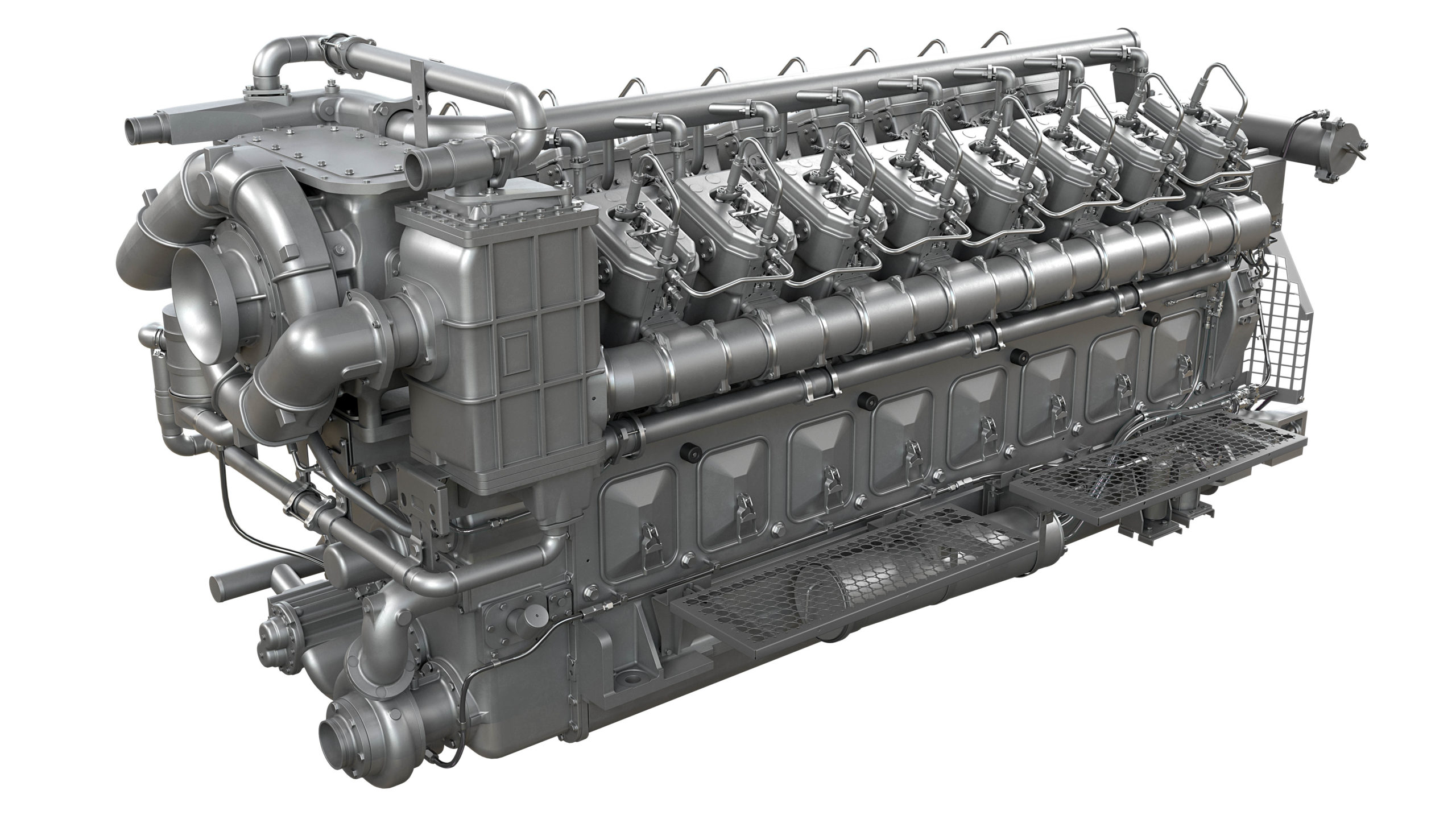

The new engine package, the FDL Advantage, aims to improve fuel economy and engine reliability. The control package, Modular Control Architecture — Fleet Migration, is a modular offering that plugs in to replace existing controls, and also is designed to improve reliability while upgrading computing power.

The goal of the engine modifications is to improve fuel economy by 5%.

“When we speak with our customers,” says Sameer Gaur, general manager, product manager, global services, “their top two costs are labor and fuel. So if you’re going to help them do a better job with fuel, that’s very meaningful.”

The engine improvements optimize the turbocharger, simplify the fuel injection system from one using 16 pumps and injectors to injectors fed by a single high-pressure fuel pump, and adds an auxiliary oil pump to serve the fuel pump.

The FDL engine “is a long-standing engine, a robust engine,” he noted. “Our customers like it a lot; it’s one they’re very comfortable with from a technology standpoint. So if we’re able to bring more value to them, it makes it that much easier for them. It’s like, ‘I can get more out of the asset that I have.”

Noted Pascal Schweizer, group president, freight global services, “This engine is still the backbone of many railroads’ operations today. … In terms of emissions and fuel consumption, it’s really a product that can make a difference.”

The modifications are designed to be as easy as possible to retrofit — which is similarly true of the new control package. Its modules are designed to plug into existing spaces, while dramatically increasing the number of connections involved. (The old system involved 20 or more circuit-board cards; the new one involves a single multi-layer board.)

“The software as well, all the programs will become modularized,” Gaur said. “We can go to market with solutions for our customers that much faster, as well. Today, if you make a switch in [for example] the traction pocket of software, you’ve got to test everything else to make sure it’s all running. When you modularize the software, you can make the change in traction and it’s not going to touch the rest. …

The two tracks of improvements also work in concert: As the new controls are installed, they will help the FDL engine work better: “The more computing capacity you’re putting on,” Gaur said, “the better we can provide fuel economy and diagnostics on that engine.”

Although this may be a great idea, it lengthens the life of engines that pollute more than the tier 4 units.

Many railroads have gotten around the tier 4 requirement by massive remanufacture programs of their older units.

This probably also means putting TO on engines that don’t have it….