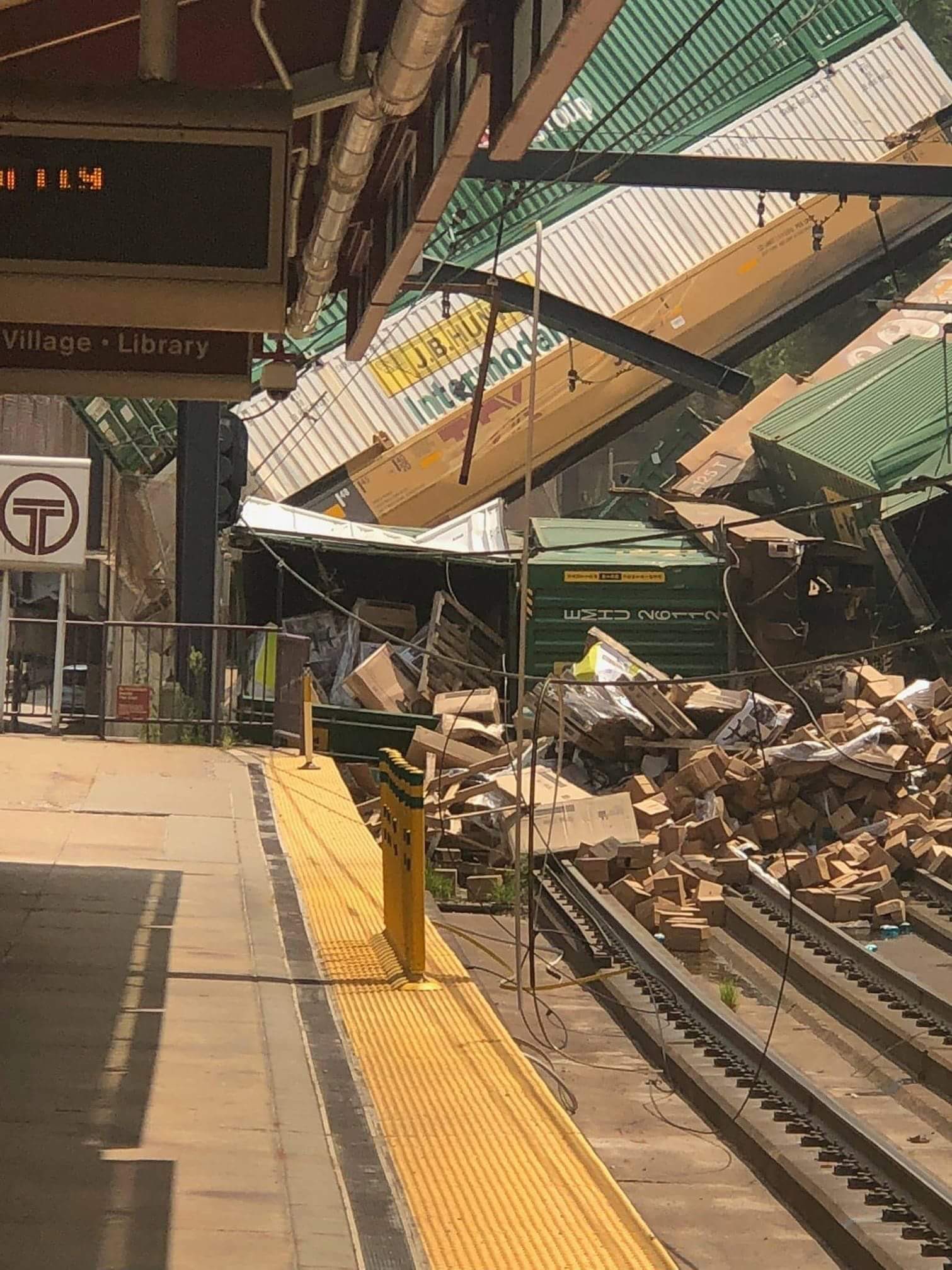

PITTSBURGH — Norfolk Southern says a broken rail caused the August derailment which sent cars from a stack train tumbling onto a station of Pittsburgh’s light rail system.

The Pittsburgh Tribune-Review reported that NS sent a report to the Federal Railroad Administration citing the broken rail as the cause of the Aug. 5 accident, which caused about $853,000 in damage to equipment and track. The derailment occured shortly after a Port Authority light rail train had passed through the Station Square stop. [See “NS intermodal train crashes next to Pittsburgh hot spot,” Trains News Wire, Aug. 13, 2018.]

NS spokesman Rudy Husband told the Tribune-Review that the track had been inspected shortly before the derailment: “We have a very robust track inspection program. We inspect our track on a very regular basis because derailments are bad for business.”

Seven cars of containers fell from a track above the Port Authority line, damaging 1,000 feet of the railroad, 1,600 feet of light-rail track and 4,000 feet of power lines. The light rail route was disrupted for several weeks.

The Port Authority declined to comment on the NS report, but said it is still calculating costs from the accident and intends to bill NS for the damage.

The FRA is continuing to investigate the incident.

I use to operate a rail test truck for the C&NW RR back in the 1980’s. At times, often due to the wear on the top surface of the rail, especially “curve worn” rail, you could not get all your sound wave energy into the rail and thus really couldn’t entirely test the rail. Wonder if that could explain how a rail defect was overlooked at this NS derailment site in Pittsburgh.

If this has happened in the middle of Kansas it would not have been as noticeable.

Murphy’s law, when something happens, it will happen, in the worst possible way, in the worst possible place, at the worst possible time! I

And it will be all over the internet.

There is nothing small about a broken rail. If a car hops off the rail it might jump back on. If the rail is broken, the car leaves the rail and all the others follow in the same path.

Fortunately, technology is developing where broken rails can be more easily spotted. But the technology is not cheap and there is a lot of rail on a railroad.

I too am glad there were not hazardous materials. To compete with trucks, loads have to get there undamaged and there is a lack of flexibility when a load is not delivered. You just can’t have a train drive all night to get it there.

That is why I am glad to see the ideas of Precision Scheduled Railroading where there is always a train leaving, instead of waiting for enough loads to run a monster train that can not fit in sidings, clogs yards and is nearly always late.

The days of big dumb everything are over for farmers, for car makers and particularly for railroads. Unfortunately big dumb and sleazy is what Wall Street rewards: act as if you are in liquidation mode, instead of staying in business for the next hundred years.

Fortunately the derailed containers held nothing more hazardous than mouthwash and dog food.

Amazing how something so small as a broken tail can cause such destruction. Never fails to amaze me what can happen with physics in a train derailment.