DARTMOUTH, Nova Scotia — A broken rail caused by an undetected fatigue flaw led to the derailment of a Canadian National train new Dunsinane, New Brunswick in October 2023, the Transportation Safety Board of Canada said in an investigation report released today (Tuesday, Dec. 17).

Four cars derailed in the Oct. 30, 2023, incident, with one leaking approximately 2,000 liters (more than 525 gallons) of methanol. No injuries reported.

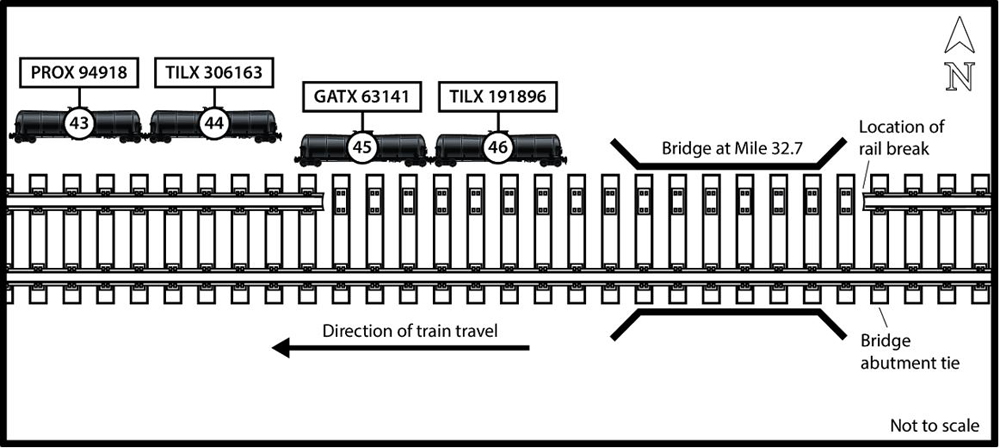

CN train L59411-30, with two locomotives, 46 cars, and a crew of three, was traveling from Moncton to Saint John, N.B., on CN’s Sussex Subdivision when the derailment occurred about 1:10 p.m. as the train crossed a small bridge. Site inspection found that a section of the north rail had broken into multiple pieces on the east side of the bridge, beginning where the rail transitioned from roadbed to the bridge. All four cars that derailed were carrying hazardous materials; none were breached, but during cleanup, it was discovered that the pressure relief device on the last car had been damaged, leading to the leak.

Visual inspection of the track had occurred just hours before the derailment. A CN track geometry car had inspected the track on Sept. 25, 2023, and ultrasonic tests had been conducted by a contractor in June, August, and on Oct. 16, 2023. None reported defects, but lab analysis of the broken rail determined that fine cracks on the surface of the rail, known as head checking, had led to the break. The head checking likely affected the reliability of the ultrasonic testing, the TSB determined.

While rail grinding had occurred on the Sussex Subdivision four months earlier, the rail on the bridge had not been included, and the extensive head checking likely contributed to the defect that caused the rail break. Also, the head checking likely affected the reliability of the ultrasonic testing, the TSB concluded. Because the rail surface conditions that affect the reliability of ultrasonic testing are not required to be reported, defects can go undetected, increasing the risk of a rail failure and derailment, the TSB said.

The full investigation report is available here.

— Updated at 5:15 p.m. to add addition image of broken rail.

Perhaps some rail replacement is overdue. The head flow and deformation is significant. Grinding or milling would not correct this.

Unless the oxidation below the top flange fracture formed after the derailment, this crack was there for some time.

An end view of the rail would help uderstand what we are looking at. My guess would be the flange side of the rail is at the top of the photo. Any educated info on the photo?

What is head checking?

“Head checking” on a rail line refers to a specific type of rail defect where small cracks or fractures develop at the gauge corner of the rail head, typically caused by repeated stress from train wheels, and if left unchecked, can grow into more serious issues like rail breaks, posing a safety risk to train operations…

Obviously, rail testing protocols need revision.