EAST PALESTINE, Ohio — During a rare on-site public hearing on Thursday, the National Transportation Safety Board delved into the chain of events that led to the venting and burning of tank cars laden with vinyl chloride following the Feb. 3 derailment of a Norfolk Southern freight train.

The big question: Was the venting and burning necessary? The decision to intentionally breach the tank cars and ignite their contents produced the towering column of black smoke that has become the iconic image of the toxic disaster.

Officials have said that they decided to vent and burn in order to prevent a catastrophic explosion that would have decimated part of East Palestine and potentially caused injuries or deaths.

But the producer of the vinyl chloride, OxyVinyls, told Norfolk Southern multiple times that they doubted that any of the five tank cars carrying vinyl chloride monomer, or VCM, were undergoing a chemical reaction called polymerization that would have set off an explosion.

None of the cars ruptured or leaked the flammable, pressurized gas during the derailment. But the tank cars were exposed to extreme heat from the ensuing fire that resulted when other cars and their contents burned.

“We made it clear, based on our expertise of the chemical properties of our product, that stabilized VCM would be unlikely to spontaneously polymerize under the conditions described to us by Norfolk Southern and its contractor,” Paul Thomas, OxyVinyl vice president of health, environment, safety, and security, told the NTSB.

NS did not pass this information along to first responders, including the East Palestine fire chief who ultimately made the decision to vent and burn.

Yet OxyVinyls’ own safety data sheet for VCM, the ingredient in PVC plastic, cautions that excessive heat should be avoided because it could lead to an explosion. That point, officials for NS and its contractors told the NTSB, was factored into their recommendation to conduct the vent and burn on Feb. 6.

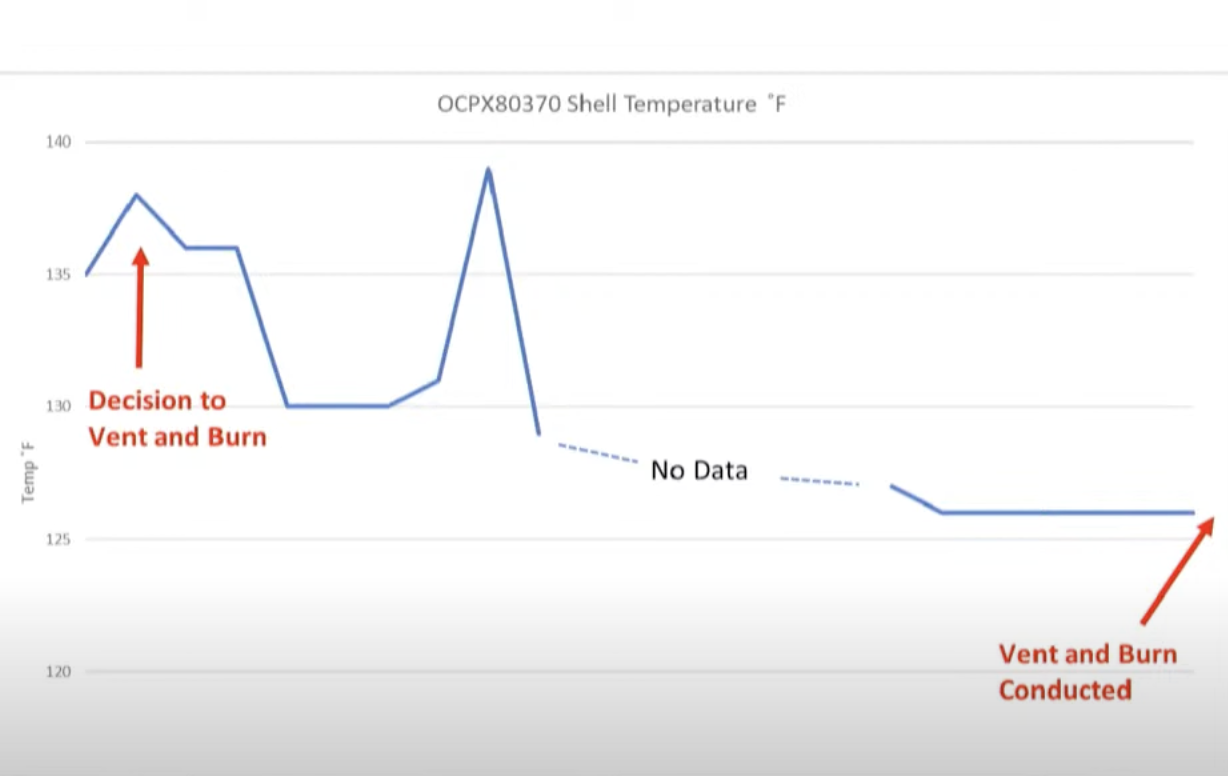

The pressure release devices on the tank cars worked as intended while the fire was burning, and potentially even emptied or nearly emptied three of the five cars. But more than 90 minutes after the initial fire burned out, officials were concerned by a sudden release from one of the tank cars. The violent release through a pressure release device lasted 70 minutes. When combined with rising temperature readings from the car, that raised concerns polymerization may have been under way.

“Collecting information on site, we observed what we believed to be multiple signs of polymerization,” Robert Wood, NS director of hazardous materials, told the NTSB.

The only way to be certain that polymerization was occurring, OxyVinyls said, was to get accurate temperature readings — something that contractors said wasn’t possible to do safely.

Story continues below

Norfolk Southern and its hazardous materials experts evaluated other options, including re-railing the cars and moving them away for transloading, unloading them on site, and “hot tapping,” which involves welding an emergency valve onto the car and then drilling a hole through the car’s metal skin. All were rejected due to damage from the wreck, thermal damage to the cars’ valves, and the potential for additional mechanical and thermal damage that wasn’t visible.

“The very last alternative is vent and burn. When you get to that point, there are no other options available to us,” Wood said.

Polymerization was just one of the factors officials considered before deciding on vent and burn. The potential that unknown mechanical or wreck damage also could lead to an explosion during cleanup was a major concern, said Drew McCarty, head of NS’s lead hazmat contractor, Specialized Professional Services, Inc.

“This is a serious X factor in our whole assessment,” he told the board, noting that his crews were never able to get close enough to do a detailed inspection of all of the wrecked cars.

NS officials and hazardous materials contractors proposed vent and burn as the best option in a meeting with the unified command. No one objected, and East Palestine Fire Chief Keith Drabick made the decision to proceed with the vent and burn. He only had 13 minutes to make the decision because weather and nightfall would make preparations difficult if a decision was delayed.

Information from OxyVinyls that the vinyl chloride was unlikely to explode would have been nice to have, Drabick said, but it would not have likely produced a different decision.

The afternoon testimony provided a window into how disaster decision-making unfolds in the midst of conflicting information, uncertainties, and problems with communication and coordination among the railroad, its contractors, the shipper, and state and local officials and first responders.

The NTSB’s questions focused on how the vent-and-burn decision was reached, whether it could have been avoided, and whether it was even necessary.

The NTSB has said that the derailment of train 32N likely was caused by the catastrophic failure of a wheel bearing on a covered hopper that was the 23rd car in the 149-car train.

Earlier, the hearing at East Palestine High School had explored issues facing first responders, including their ability to acquire information on the hazard materials in the train’s consist [see “NTSB hearing on East Palestine derailment begins …,” Trains News Wire, June 22, 2023]. The hearing will resume today at 9 a.m. EDT with a session devoted to wheel bearings and wayside detectors, before concluding by addressing tank car safety beginning at 2 p.m. EDT.

The hearing is being streamed live on the NTSB’s YouTube channel.

The primary reason for a Material Safety Data Sheet (MSDS) is to provide information and guidance in situations just like this. I spent 42 years in the aerospace/defense world, often working with or around hazardous materials. Over and over it was drilled into my coworkers and me that, in the event of a spill, fire, or other incident involving HAZMAT, you gotta treat the injured, ensure the safety of other bystanders, and ***READ & FOLLOW THE MSDS***.

Given the information obtained therefrom, I’d say the responsible parties involved did the right thing. Maybe somebody should be smacked for inadequate communication, but officials from the chemical company should not go public by second-guessing the information in their own MSDS.

Let’s say that the decision to vent & burn WASN’T made, and everything went “boom” in a spectacular fashion. Do you believe for one microsecond that the OxyVinyls people would have said, “Gee, we didn’t think it would do that…”?? Hell, no; they would have said, “Why didn’t you follow our MSDS?” and left the responsible parties hanging out to dry.

The responders and decision-makers should be given hearty thanks, and the OxyVinyls spokesmonkeys should be told to get stuffed.

“What we’ve got here is failure to communicate.”

The prior day’s hearing disclosed communication was a problem among the first responders. Who was in charge? Was that person or activity’s frequency or phone disseminated to the parties involved. Who did NS inform of their experts’ conclusions?

I’m not sure what an oxymoron is BUT, Gerald’s comment seems to be one.

“I wouldn’t trust the manufacturer to admit their product is at risk of exploding…that wouldn’t look good to the public.”

IMHO If they did not warn, they are bad business and not trustworthy, on the other hand when they show data as was in the article, they are being honest and helpful. endmrw0623231431

This sure is a bad thing for NS, (above) “NS did not pass this information along to first responders, including the East Palestine fire chief who ultimately made the decision to vent and burn……….(above)”Information from OxyVinyls that the vinyl chloride was unlikely to explode would have been nice to have, Drabick (mrw edit…poor Fire Chief who gave the order to vent) said, but it would not have likely produced a different decision.”

But then again at the time it MIGHT have caused him to NOT vent. Reference: The graph in the article is informative. AGAIN total info was NOT passed forward to all, as it should have been. And by the way (not confirmed) it seems the Fire Chief ordered self interest RR person off property as local department was in charge. endmrw0623231414

Further: “The pressure release devices on the tank cars worked as intended while the fire was burning, and potentially even emptied or nearly emptied three of the five cars.”

Heat is released upon polymerization. Did the manufacure assure the decisoono makers on site, thatspontanieous polymerization would not have occured?

So when someone uses the word doubt and unlikely they are basing it on theory. Nothing is predictable with a burning vessel.

During the 1979 Mississauga derailment a loaded tank car did explode and landed 2000 feet away in an empty field, it’s now part of one of Canadas largest cities, 250000 people evacuated back then.

Have a read of The Mississauga Miracle.

I wouldn’t trust the manufacturer to admit their product is at risk of exploding…that wouldn’t look good to the public.