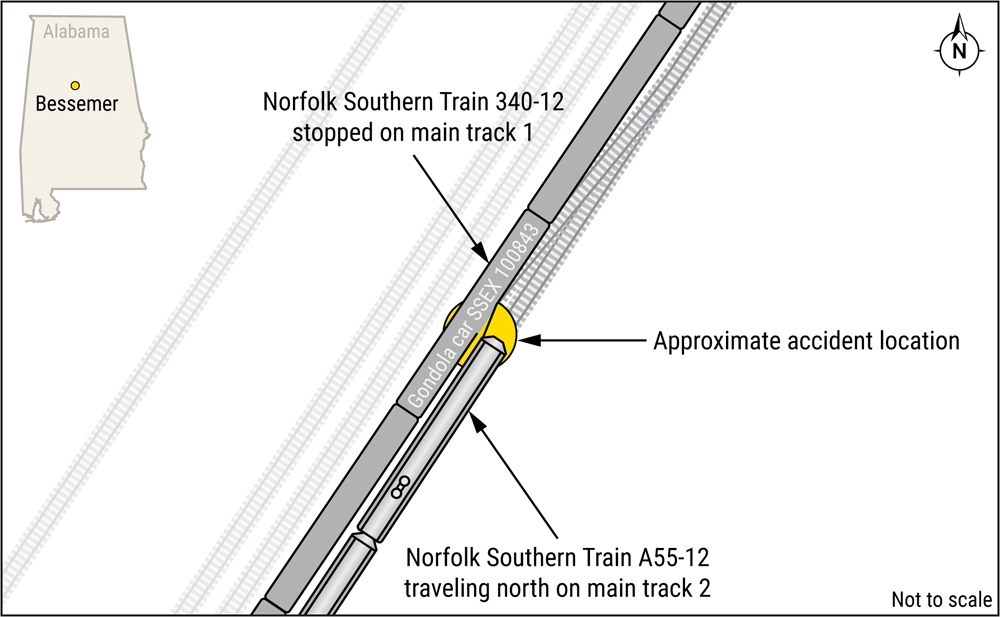

WASHINGTON — A segment of steel angle iron protruding from a gondola car on a stopped train killed a conductor trainee and seriously injured a conductor on an oncoming Norfolk Southern train, according to the National Transportation Safety Board’s preliminary report on the Dec. 13, 2022, accident in Bessemer, Ala.

The preliminary report, issued Tuesday, Jan. 17, indicates the ongoing investigation will focus on NS freight car inspection practices and on NS and U.S. Pipe operating procedures for unloading cars and returning freight cars to NS. Preliminary reports do not reach conclusions as to probable cause of accidents and contain information that is subject to change.

Walter James Griffin III, 43, of Hueytown, Ala., was killed in the accident [see “Norfolk Southern trainee killed …,” Trains News Wire, Dec. 13, 2022]. Federal Railroad Administration had previously issued a safety bulletin urging railroaders to conduct pre-departure inspections to ensure no objects are protruding from freight cars [see “FRA issues safety bulletin …,” News Wire, Jan. 6, 2022].

The preliminary report says that the angle iron — in this case, a piece of metal more than 16 feet long with 5-inch sides — had been welded to the top right edge of gondola car SSEX 100843, which was in the consist of stopped train 340-12. The metal piece had broken loose and was fouling the adjacent main track when train A55-12 approached at approximately 55 mph. The angle iron pierced the window on the left front door of A55’s lead locomotive and struck both conductors.

Also remember the old EL (Erie) across Ohio & Indiana. Distance between track centers were a lot wider than on most other railroads. Had the passing tracks been further away, maybe the accident could have been avoided.

What are the rules for engineers on trains moving on the left hand side of a two track line?

Gondola cars that are consistently used in scrap metal loading take a lot of abuse. Heavy pieces dropped by magnets into the car. Crane operator hitting the side of the when loading. I remember a story from 30+ years ago where a scrap dealer’s crane had worn out brakes on the rotating portion of the crane. The operator would pick up a load of scrap and swing it around with the load intentionally hanging below the top of the car; so that it stopped the rotation when the load hit the side of the car. I expect that the 16-foot piece of angle iron had been welded on the car to reinforce the top chord of the gondola.

Scrap unloading is probably the most brutal environment for any railway car, essentially a large battering ram, the magnet we were using at the time weighed 8 tons.

We had a gondola years ago get lifted off the truck at one end with the scrap handling magnet and when the crane operator sat it back down the kingpin missed the hole in the bolster. Made it a few miles out to the local classification yard before a car checker found it.

Over fifty years ago, on my first student trips I was taught that when passing another train on an adjacent track to get off my seat in the cab and stand on the side that was opposite of the the train being passed in order to avoid injury should anything be sticking out of the the adjacent train that might foul our train. Guess they didn’t/don’t teach that anymore. Perhaps that simple act has a negative impact on the operating ratio?

Totally avoidable fatality and injury. Truly a shame.

Amtrak rules require anyone sitting in the firemans seat to get up and move to the center of the cab when meeting or passing a train. Needless to say very few people actually do it.

Sounds more like the shipper did not remove everything that was welded onto the gondola to keep the pipe load secured in transit.

Sounds like the car had been repaired and possibly some of the welds on the angle iron used in the repair might have failed while the car was in transit as a result of maybe rough track or train handling, causing the iron to swing away from the car.

In addition, suggest consistent application and enforcement by carriers (and therefore compliance by shippers) of loose material loads that are above the top level of a gondola. And while they’re at it, how about carriers (via T&E crews) refusing to switch a shipper location where there is loose, dangerous, heavy material alongside the ROW in the shipper location.