Larry appears on Kalmbach’s videotape “TRAINS: Railroads and Intermodal,” where he offers a candid assessment of the industry and walks viewers through the variety of intermodal offerings available to shippers. What follows is a transcript of the complete interview, conducted at Wabash National’s headquarters in Lafayette, Ind.

What’s the basic premise of intermodal transportation?

The basic premise of intermodal is an attempt by the railroads to combine the efficiency of rail with the flexibility of highway.

What you’re really trying to do is use the flexibility of truck for pick-up and delivery, and then somehow capture the efficiency of rail for the line haul.

The challenge that entails is that the economics of intermodal are very affected by the distances involved in the truck-hauling segment. The closer you can get to where that freight is originating and terminating on rail, the more efficient you’re going to be, because you’re utilizing the economics of rail for as much of the journey as possible.

Working against that is the fact that the only way you can get rail economics is if you run a big train, so you can’t have a whole bunch of terminals located all over the map. You want to minimize the highway distance, but at the same time you have to have enough volume originating at a terminal going to any given destination to warrant a trainload.

So you’re always fighting that balancing act.

How does the process work?

Let’s say you were moving a load from Detroit to St. Louis.

If you do it by truck and you’re the shipper, you get on the phone and call one of the truck lines. They route a truck which has recently become available close by – they’re monitoring that on a real-time basis. The freight is loaded, and the truck immediately heads to St. Louis and unloads.

There’s an extremely small amount of wasted motion or wasted cost, and it’s a very good service, because essentially the capacity is there when you need it, and you just call on that capacity.

Now let’s look at an intermodal move.

Typically, you don’t call a railroad for the intermodal move, because the railroad is not marketing that service. You call an intermodal marketing company, or you call a trucker that uses intermodal. They’re going to route a piece of equipment that might belong to them, or it might belong to the railroad or a leasing company.

A drayman, who is a specialized trucker moving the freight between origin and the intermodal terminal, is going to bring that trailer to you for loading, and then bring it over to the intermodal terminal, which may not be, and often is not, in the correct direction of where the load is eventually going.

So you’re actually accumulating miles – and cost- going in the wrong direction, just to get to the point where you can get on the rail.

At the intermodal yard, there’s a whole process at the gate where the trailer is inspected, because the possession of that trailer is changing from the drayman to the railroad. Each wants to make sure that they’re only responsible for damage they alone may have caused the trailer. The railroad inspects the condition of that trailer, making notes of any discrepancies it finds. All of this has quite a bit of cost associated with it.

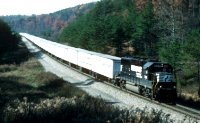

And then you’re going to assemble the train, out of let’s say fifty or a hundred trailers, or if it’s a double-stack train, maybe 280 containers.

The train runs from Detroit to St. Louis, and then you repeat that whole process. Disassemble it, get it back out on the street, and get it over to the customer.

With all of the strides railroads have made in intermodal transportation, why are there still so many trucks on the highways?

It seems so obvious when you look at a hundred-trailer train barreling down the tracks at 60 miles an hour, two individuals up in the cab of the locomotive, and you say, “How could that not be efficient? How could that not make sense?”

But the problem is that you’ve got to look beyond just the rail portion. The goal of any transportation system is to move freight from door to door, and you’ve got to look at the door-to-door costs of that move.

Transloading trailers at an intermodal terminal takes time and costs money. You’ve got a $750,000 gantry crane that’s picking the trailers up and putting them on a flatcar. You’ve got a multi-million-dollar terminal where all of this occurs.

And it’s only after you’ve finished all that, that you start to gain on the truck, in terms of economics.

And incidentally, in all the time that’s been consumed there, the truck’s already been rolling toward its destination.

That’s one reason why intermodal is generally not quite service competitive with truck except in the longer lanes of haul – because of all the activity that needs to occur before you really start moving the freight towards its destination.

Given the enormous investment required, and the comparatively low profit margins it generates, why are railroads so intent on increasing their intermodal business?

Well, the biggest challenge right now, as with any business, is that railroads need to grow to survive.

And intermodal is the only place where that growth can occur, other than bulk commodities like coal. If the use of coal goes up, then railroad ton-miles go up. But railroads really can’t control that.

If railroads want to grow their business, the only way they can do it is through intermodal. Especially since all of the shortcomings that we talked about are multiplied greatly when it comes to carload freight. A boxcar is only suitable for the lowest value, least service-sensitive commodities that are out there.

Intermodal really came into being as a means of defending the merchandise segment against the inroads of truck. It was all moving in boxcars at one time, then truck came along, and intermodal was created to try and stem the tide.

What are shippers looking at when deciding whether to move their freight by truck or rail?

If I’m a shipper, there are a few things I’m going to look at.

I’m going to look at what the service is. How long does it take from the time I pick up the phone to say, “I’ve got a load that’s ready”? How long does it take for that freight to arrive at its destination?

I’m also going to be worried about how reliable that service is. Not only when will it get there, but will it get there when you say it will get there?

And then I’m going to worry about what it costs. The rail part of an intermodal movement is only one piece of the door-to-door service, and overall economics are what’s going to govern whether something goes on a truck or something goes by rail.

Generally speaking, truck is going to be more reliable than intermodal because there are fewer moving parts to the process. You don’t have 14 different people touching the trailer – truckers, terminal people, rail people – so there’s a lot less that can go wrong with truck. In terms of speed, it’s going to be faster, because you don’t have to wait to assemble a train and go through the process of trying to put 100 trailers together. So except for the very longest distances, if I’m worried about reliability or service, I’m going to tend to want to use truck.

The third part of the equation is cost. If rail can offer lower cost, then I might be willing to take a little bit slower service or a little less reliability. And the way that intermodal economics work, intermodal can provide a lower cost if you are going far enough.

So the short answer is if you’re not going very far, or you need very reliable service or relatively fast service, you’re going to put it on a truck. If you’re going a long way, if you can accept perhaps a little less reliability and a little less speed, then you might consider putting it on intermodal.

Who are the various types of intermodal shippers?

You’ve got a bunch of different users. You’ve got people like UPS and Roadway, the LTL or less-than-truckload motor carriers that are using intermodal on the longer lengths of haul. Their ability to do that is limited by the agreements they have with their teamster drivers. Only a certain percentage of their freight can be put on rail.

UPS is a large intermodal user. They are one of the drivers of the U.S. intermodal system, although UPS is quite different than some of the other users out there. They’re dealing with packages, not truckload. Their service requirements are completely different. They have enough volume that the railroads are literally willing to run trains for UPS’s benefit to meet their specific service requirements. The railroads and UPS have a great working relationship. I just wouldn’t say it’s terribly representative of the rest of intermodal.

Then you’ve got the truckload motor carriers like Schneider National or J.B. Hunt that are selling a door-to-door service and using the rail as a line haul.

You’ve got what are called IMCs – Intermodal Marketing Companies – that are packaging the intermodal service. That would be groups like Mark VII or Hub City that put all the pieces together to form a door-to-door service.

You’ve got stack train operators like Pacer that are big intermodal users and big intermodal providers.

Finally, you’ve got the shipping lines like Sea-Land and APL that are using intermodal to move their international containers inland from coastal ports. They are big intermodal customers, although rail comprises a relatively short part of the total move. And it’s much less service-sensitive than a domestic move.

What types of intermodal choices are available?

There are three main technologies that are available.

The oldest is piggyback or TOFC, trailer on flatcar. Then you have COFC, container on flatcar, which has evolved into the double-stack container system. The third is the RoadRailer system.

Which technology you use is dependent on the market that you’re trying to hit. There are two broad intermodal markets: international freight and domestic freight.

International freight relies exclusively on containers. Why?

With international shipping, freight is coming in a piece of equipment called an ISO container, which is an international container, typically a 40-foot-long box.

There is no question that double-stack is the most efficient means of moving that type of freight in the main lanes where you’ve got large volumes moving in a concentrated fashion in these containers.

Of course you will always have large volumes entering a port, because any ship that comes in is carrying thousands and thousands of TEUs.

(A TEU is a Twenty-foot Equivalent Unit, a 20-foot container. The first international containers used were typically 20 feet long, and that terminology gained a foothold, so we still talk in terms of TEUs when we talk about ship capacity.)

Each 40-foot container is two TEUs. One ship can carry thousands of TEUs, and therefore can fill multiple numbers of double-stack trains of 200 to 250 containers.

Double-stack technology has as its primary advantage the ability to move a tremendous number of containers in one train. That spreads the cost of operating the train over a large number of containers. And that’s how it generates a low cost per container.

The disadvantages are that when you put together large quantities of containers, it takes a long time to assemble a train, and there are only certain lanes that can support those kinds of volumes. When you start to move out of those lanes, the economics begin to erode.

Containers have made inroads in the domestic freight market as well.

In the major lanes, railroads have been very successful using what’s called a domestic container. That’s typically a larger and lighter-weight version of the 40-foot international container.

It’s 48 feet long, moving to 53 feet long, and it has a bigger door opening to try to approach the qualities of a trailer.

What factors would a domestic shipper take into consideration when deciding between trailers and containers?

The first question asked would be, “will my load fit in the vehicle?”

You might say, “Well, what’s a couple of inches?” And the answer is, not much, until you have a product that’s one inch too big, or a stack that’s one inch too tall.

Then it gets to be a real issue, because then you will have to ask that shipper to do something different than he or she normally does in order to use a container. And that is always a problem in business, when you ask somebody to do something different in order to use your product.

When it’s on a chassis, the container is also heavier than a trailer. So in terms of the load-carrying capacity for heavy payloads, it’s somewhat impaired.

Finally, there are still users for whom a container is not suitable – UPS is one, Schneider National would be another. These are people that are running trailers throughout their system. It would be tremendously difficult and costly for them to say, “okay this load goes in a container, this load goes in a trailer,” depending on whether it’s going on rail or on highway.

So they’re saying to the railroads, “if you want to move our freight, you’ve got to do it in a trailer.”

And typically TOFC is the answer for that.

So as long as railroads are competing with trucks, trailers will still be an integral part of a railroad’s domestic intermodal offerings?

Absolutely. Domestic traffic is quite a bit different from international traffic. You’re typically going to have a higher service standard, and also you’re competing against a truck trailer.

Whereas international containers are all standard 40 feet long, the typical trailer that’s running down the highway today is a 53-foot-long trailer. It has a door opening at the rear that’s in excess of 110 inches high. It has an interior width of 101 inches or more.

These dimensions are larger than both domestic and international containers. They’re limited only to the extent that the size of the outside box is limited by law. You can’t have longer than a 53-foot trailer, it can’t be more than 102-3/8 inches wide, and it can’t be typically more than 13 feet, 6 inches tall (although many Western states allow trailers that are 14 feet tall).

The other part of the equation is that typically, in the United States at least, the rig (including the power unit or tractor), the trailer, and the payload combined can weigh no more than 80,000 pounds.

So trailer manufacturers are trying to get as much freight-carrying ability into that trailer as they can. Every pound that we take out of the trailer is another pound of cargo that we can carry, making that trailer more efficient. The weight of trailers has continued to go down over time, so we are continually improving over-the-road trailer technology.

Is it only the federal government that regulates trailer length and tonnage?

Both states and the federal government have laws regarding vehicle size and vehicle weight.

The 80,000-pound maximum weight and 53-foot length are national standards, regulated by the Federal Highway Administration, part of the DOT.

It’s possible in certain states to run a heavier trailer within that state. For instance, in Michigan and in Washington, you can make trailers heavier by putting more axles underneath. You might see trailers in Michigan that have six or even eight axles under them, as opposed to the two axles that are typically used.

A normal rig has five axles: a steering axle and two drive axles in the tractor and another two axles on the trailer.

Given that trailers can hold more cargo and are more compatible with the over-the-road trucking system, why switch to domestic containers at all?

There is a tremendous amount of weight associated with putting that trailer on the rail.

Assume the typical trailer might carry, on average, 30,000 to 40,000 pounds of freight. The trailer itself is probably a 14,000 or 15,000-pound item. Then you’re going to put that trailer on a flatcar, and even if it’s a lightweight articulated spine car, that adds probably another 35,000 pounds of steel.

So now you’ve got more weight involved with the equipment than you do actually in payload. The net-to-tare weight of piggyback is not that good.

The domestic container provides better economics than piggyback – because its net-to-tare ratio on rail is better and the number of freight-carrying units per train is greater – but then you have to deal with the container’s service and capacity shortcomings, which we discussed earlier.

How do you solve that dilemma?

That brings us to the third technology, which is the RoadRailer.

What we’re really trying to do with RoadRailer is truly get to that holy grail of an intermodal product that’s “truck-like,” meaning having as close to the same service characteristics as truck: fast, and a trailer that you don’t have to load differently just because it’s going on the rail.

Whereas with TOFC to a great extent, and double-stack to a lesser extent, you need to load the trailer differently – put more blocking and bracing in to keep the load from shifting because of the slack action and the lifting on and off of the flatcar – you don’t have that with the RoadRailer system. You have a slack-free coupler and you have an extremely lightweight 53-foot trailer, so on rail it’s highly fuel efficient, it’s fast, and it gets in and out of slow orders quickly.

What we’re trying to do is create a real truck-like intermodal product that will let the railroads go in and compete for the high end of the freight market, which is typically moving directly on highway today.

Because RoadRailers units are specialized trailers that aren’t really compatible with other types of rail equipment, aren’t you asking railroads to do something different?

I think one of the things that has held the railroads back is the need to assemble a full trainload of RoadRailer equipment and penetrate a particular market between two cities to make the technology and the economics work.

Having said that, we’ve done testing and computer analysis that tell us that RoadRailer equipment is capable of being operated on the back of conventional intermodal trains under certain conditions with limitations. In fact we are running that way in Mexico today. The TFM railroad is running RoadRailer equipment on the back of some of its intermodal trains.

The Federal Railroad Administration, which has jurisdiction over RoadRailer operations within the United States, is evaluating whether or not to permit that here in the states, either on a full-time or an experimental basis.

Triple Crown Services uses RoadRailer trailers to haul auto parts, which on other railroads typically moves in boxcars. Since I presume there are rail sidings at each endpoint of that run, what’s the advantage of using trailers?

Well, the advantage of using a RoadRailer, truck, or any intermodal system over a boxcar for a flow-processed commodity like auto parts is that the move is far faster, and the transit time from dock to dock is more consistent.

American industries have gone to something called “Just-in-time” inventory. Rather than having large warehouses full of parts, the auto industry finds it much cheaper to have the parts arrive just in time for when they’re needed on the assembly line. In order to achieve that, you’ve got to have very reliable service. You’ve got maybe a 15-minute window for when that trailer needs to arrive at the dock.

Using intermodal equipment can also help an auto manufacturer improve his quality. Let’s say you have a machined component that is made in Detroit and is shipped to an automobile assembly plant in St. Louis. Suppose the machine in Detroit somehow gets out of tolerance, as sometimes happens, so that the parts it’s producing don’t quite fit like they should. You want to have as few of those parts as possible in the system when you discover that problem.

If you have, say, 10 or 20 boxcars that are en route to the plant before you discover the problem, your problem is much bigger than if you just have a trailer load or two.

Who are some of today’s RoadRailer customers?

In terms of high speed and high service, probably the most interesting was Amtrak, which until 2004 ran an extensive network and quite sizable fleet of RoadRailer equipment on the back of its passenger trains to carry what was termed mail and express, which is essentially high-service, high-speed commodities.

One of our newest users is TFM, which is a Mexican railroad that runs between Laredo on the U.S. border and Mexico City. They’re using RoadRailer equipment really as the first domestic intermodal service in Mexico. We built them some special RoadRailer trailers for Mexican service.

In 2001, we built our 10,000th trailer, and that year, there were about 8,500 RoadRailer trailers running on railroads in the U.S., Canada, and Mexico.

In addition, we are also using the RoadRailer technology across the globe. We’re running in Australia, we’re running in Europe, we’re testing in Thailand, and we’re testing in China. So it has become quite an international technology.

What sort of trends are you seeing now with the way railroads are handling intermodal?

Right now one of the big thrusts is to try and get to a more truck-competitive piece of equipment for domestic intermodal, which means a 53-foot piece of equipment.

One of the handicaps railroads have always operated under with intermodal is that the size of the trailer has evolved faster than the railcar fleet that supports it. That has been a major shortcoming in years past when the over-the-road motor carrier was able to move from what was originally a 40-foot trailer, to a 45-foot trailer that was 96 inches wide, and then a 48-foot trailer that was 102 inches wide, and now a 53-foot trailer that’s 102 inches wide.

The problem for railroads is they still have a lot of 89-foot TTX flatcars out there that were originally designed to handle two 40-foot trailers. And when those larger 53-foot trailers arrive at the ramp, you can only fit one of them on an 89-foot car.

So you have a tremendous amount of wasted weight and wasted space. Those aerodynamic gaps in the train are extremely damaging when it comes to fuel efficiency. It takes a tremendous quantity of fuel to move a train that has a large number of gaps in it.

So one of the challenges that railroads will always face is trying to track the technology on the highway side when they are constrained by the size of the railcars they have available.

That is one of the benefits of the RoadRailer system. The RoadRailer bogie can be put under any size trailer, and we can mix them up in a train with no gaps. As soon as the highways go to a new trailer size, we can build a RoadRailer trailer of equivalent capacity and equivalent dimension.

What are the long-term prospects for North American railroads that hope to grow by capturing more intermodal business?

Intermodal will prosper to the extent that the railroads are able to continue to provide a product that meets the customer’s needs. And the rate of growth of intermodal will depend on how flexible the railroads are in providing intermodal products that meet the various needs of the various segments of the freight transportation market.

I am confident that it has a very bright future. That’s why we’re involved in the game. We supply RoadRailer trailers, piggyback trailers, and domestic containers. We think that technology has a role to play there. And there will continue to be multiple technologies that are out there in intermodal, because no single technology is the answer for all market segments. To the extent that we try and force all market segments to a single technology – be it container or TOFC or RoadRailer – we will be forfeiting some of the potential that intermodal has to offer. If we can get to a multiple equipment philosophy, where each individual technological tool is used to its best advantage, then I think you’re going to have the most robust and the most energetic intermodal system.

The main challenge with intermodal is trying to become ever more reliable and be ever able to provide better value for the customer’s transportation dollar. That is, I believe, an unending battle, but hopefully one that we will be successful at. And intermodal will have its continuing place in the sun.