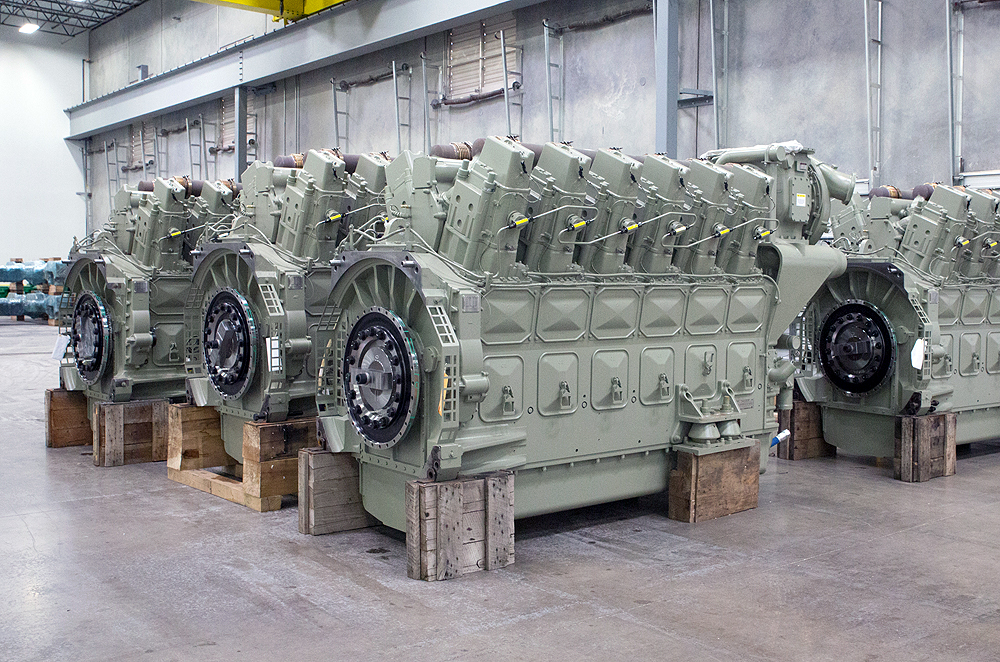

Locomotive prime movers are the engines inside all diesel-electric locomotives and are the heart of the entire locomotive. Prime movers provide enough power to pull both the locomotive and any freight cars attached to it, while also producing enough extra output to support the power needs of the various systems on the locomotive such as headlights, computer systems, and cooling fans.

Each prime mover can be rated at different levels of horsepower or built with a different number of cylinders. Some can be built with different features to increase horsepower, such as a turbocharger.

Since the same prime mover can produce different power amounts, a locomotive design is tailored to support a prime mover producing a particular horsepower output. From the cooling system to the traction motors underneath, everything is balanced to work well with a specific horsepower output.

On Class I railroads, rosters are predominantly a two-builder affair, with Wabtec (formerly General Electric) and EMD locomotives dominating the Class I rosters. Wabtec has used the four-cycle 7FDL design since the mid-1950s, then switching to the GEVO prime mover domestically in the mid-2000s. Class I railroads currently employ both the 16-cylinder 7FDL and 12-cylinder GEVO-12 prime movers in their GE locomotives.

EMD locomotives on Class I railroads employ four different engine designs, the 567, 645, 710, and 1010J prime movers. The first three are two-cycle designs with the 567 installed in new locomotives from the mid-1930s to the mid-1960s. This is the least common in the industry with any remaining prime movers on Class I railroads typically using newer 645 engine components internally.

EMD’s 645 prime mover replaced the 567 and was used until the early 1980s when the 710 was introduced. The 710 also suffered the same fate as the 7FDL when emission requirements forced the prime mover into domestic retirement, replaced with the 12-cylinder 1010J engine in 2015. This is the first four-cycle engine used inside EMD locomotives.

Class I railroads have a mix of EMD prime mover sizes across the 567, 645, and 710 series, ranging from 8, 12, 16, and 20 cylinders in their fleets. Union Pacific also has a small fleet of rebuilt EMD locomotives with 12-cylinder Caterpillar 3512C HD engines.

Gensets are less common today on Class I railroads, and the remaining locomotives use engines from different builders. National Railway Equipment gensets have Cummins 6-cylinder QSK19 prime movers and Railpower gensets have 8-cylinder Deutz V-8 2015.

Several of Progress Rail’s repowered locomotives have Cat 3500 and C175 prime movers.

Then there are the Cummins engines used by Siemen’s Mobility – most notably in the current order for 75 new engines for Amtrak.

Poor EMD got caught in the last emission upgrade to Tier 4 requirements, striving mightily to tailor their 2-stroke prime mover to the new specs with no success. So they also moved to 4-stroke with the 1010, but very late. GE was ready in 2015 when Tier 4 began — EMD (now Progress) did not have a production unit until 2017 or so, and GE (Wabtec) took over the market for new locos. Very few 1010 locos have been built, and I understand that even fewer are in daily use.

Emphasis today is in rebuilding older units to modern specs with upgraded prime movers and controls. Re-manufacturing is the current mantra.

Four STROKE or two STROKE! The number indicates the piston strokes in each power cycle.

EMD units are Still in Use