Railroading tools

Railroads are fixed-guideway systems for transporting goods or people. Its basis is the low friction, and hence high efficiency, of a hard wheel rolling on a hard surface. They are made up of many elements: people doing different jobs, and hardware for them to use. The jobs range from laborer to strategic planner. The tools can be as simple as pieces of wood and steel fastened together, or as sophisticated as computerized dispatching systems.

The technology is both ancient and modern — its basics have changed little in nearly 200 years, yet some elements are spinoffs of space exploration.

The two features that set railroads apart from other modes of transportation — and make them so appealing to so many people — are its rolling stock (locomotives and cars) and its roadway (track). Some of the most basic components of roadway and rolling stock include:

Basic components

AUTOMATIC COUPLER: Couplers work as clasped hands. A movable knuckle is automatically locked in place by a pin when two cars come together. Uncoupling is accomplished by manual operation of the cut lever, which releases the pin and unlocks the knuckle, allowing it to open as the cars are separated. Other, fully automatic, designs are used on captive equipment such as fleets of commuter cars.

ANGLE COCK: In the open position, allows brake-pipe air to flow from car to car; when closed (as on the end of a train), keeps air in system.

AIR-BRAKE HOSE: Brakes work by air pressure. Cars are linked by hoses to each other and the locomotive, whose air compressor maintains pressure in the brake pipe, or train line. To set brakes, the engineer reduces pressure in the line, causing a valve on each car to draw air from a reservoir, increasing pressure in the car’s brake cylinder. As the cylinder’s piston moves, linkages force brake shoes against the car’s wheels. The system is nearly fail-safe, if it is fully charged at the start of a run — any event causing a loss of pressure in the line causes the brakes to apply.

WHEEL: Each pair of wheels, connected by an axle, is called a wheelset. With few exceptions, cars have eight wheels, grouped in two sets of four in swiveling assemblies called trucks. Bearings on outer ends of axles are connected to truck frames.

FLANGE: A key element of railway technology — a small lip on inner edge of the wheel which keeps rolling stock on the rails. Flange depth is only about 1 inch.

TRACK: Straight (called tangent) or curved. Curvature of track is measured in degrees: most mainline curves are 1 or 2 degrees; track in rough terrain can have 10 degree curves or sharper. Slope, or grade, of track is measured as a percentage of distance climbed per distance traveled forward. Track that rises 1 foot over 100 feet of distance is a 1% grade, which is a significant challenge to a heavy train. Grades steeper than 3% are very rare.

RAIL: Made of high-quality steel. Three parts: head, web, base. Measured by weight per yard: most mainline rail is in 130- to-140 pounds range; some light-duty track has much lighter rail. Standard rail length was once 39 feet, with sections joined by bolts and angle, or joint, bars. Jointed rail remains on lesser used routes, some sidings and tourist lines. The standard now is continuous welded rail. Joined into 1,500-foot lengths at special plants, CWR is transported to the field, where even more joints are welded after it is laid, creating a smooth surface for trains to traverse.

GAUGE: The distance between the inner faces of the rail heads is 4 feet 8-1/2 inches for standard gauge. Used throughout North America and Europe, it originated in England and matches the spacing of ancient wagon wheels. Variations from standard (rare in the U.S. and Canada) are termed either narrow gauge or broad gauge.

SPIKE: Four or six per tie (three or four for each rail, more on curves), driven through tie plates into cross tie to secure rail in place. Clips and special tie plates are used increasingly with wood ties, and always with concrete ties.

CROSS TIES: Most ties are of treated hardwood, though concrete is gaining favor because of its greater strength and durability. Spacing varies according to traffic: closer for heavy traffic, farther for light use.

BALLAST: Crushed rock to keep track in horizontal and vertical alignment and properly drained. Laid over gravel sub-ballast and earth sub-grade.

- Boxcar: For general service, especially loads needing protection from weather. Loaded/unloaded through side doors. Refrigerator cars are similar, but have mechanical cooling equipment.

- Tank car: For gases and bulk-quantity liquids like corn syrup, petroleum products, and other chemicals. May be interconnected with hoses to speed the loading process. Two types: pressurized and non-pressurized.

- Hopper car: For bulk commodities not needing weather protection like coal and stone. Sloped floor sheets at ends facilitate unloading through doors in funnel-like bins at the bottom of the car.

- Covered hopper: For bulk commodities like grain needing weather/contamination protection. Loaded through roof hatches, unloaded like an open hopper. May have flat or rounded sides.

- Gondola: For loads like iron and steel products, scrap, pipe, logs or other odd-shaped materials. Some have removable roofs and/or special body design. High-side types carry coal, are turned upside down in dumpers to unload.

- Flatcar: For loads, often large objects, not requiring weather protection. Cars with end or center bulkheads are for wood products. Intermodal cars carry truck trailers and containers.

- Auto rack: A significantly modified 89-foot intermodal flatcar fitted with decks, walls, roof, and end doors for carrying automobiles and light trucks on two or three levels.

- Double-stack car: For intermodal containers stacked two high in a lowered area, or well. Some fitted to carry single trailers too. Can be a single, eight-wheel unit or articulated (sharing trucks) with adjacent cars.

Other tools, and their uses

Freight cars are assembled into trains in areas of many tracks called yards. These range in size from small staging areas to giant classification facilities. The biggest and busiest have small humps, or hills, over which cars are slowly pushed; such hump yards thus use gravity to speed the process of grouping cars into trains.

Most freight trains are staffed by two people: an engineer, who operates the locomotive, and a conductor, who is in charge of the train. Some trains also carry a brakeman to help with switching maneuvers, though the job title dates from the manual-brake era.

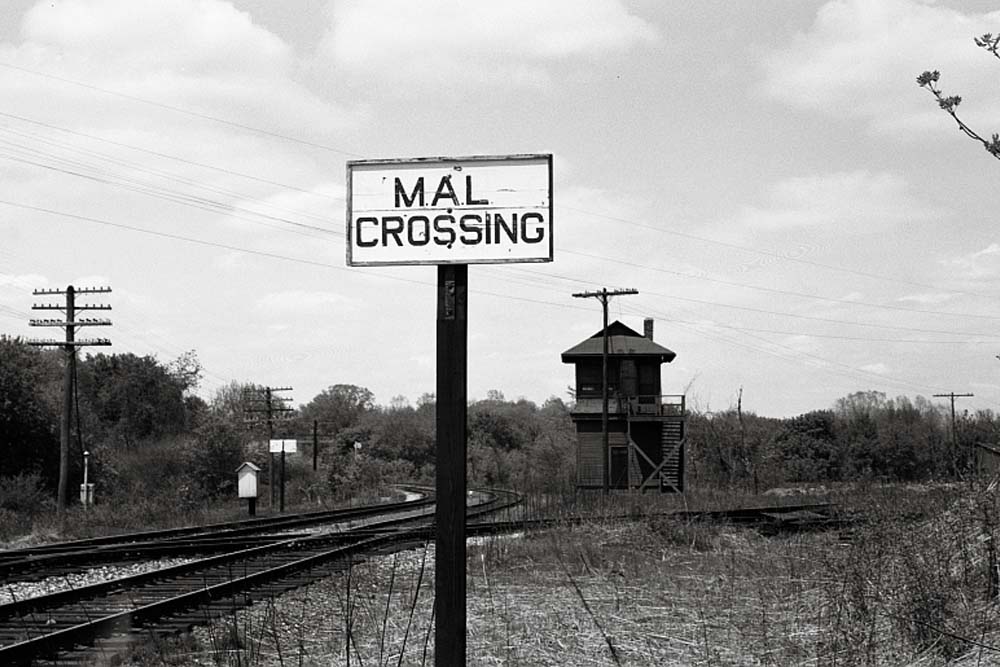

The dispatcher plans and controls the movement of trains. Most rail lines have only a single track; when two trains must meet, the dispatcher routes one into a passing siding. Most big railroads now have centralized dispatching centers covering all or large parts of their systems. Here, dozens of dispatchers, each responsible for a certain territory, keep train operations safe and fluid. A time-tested method of keeping trains separated is the block system, where rail lines are divided into segments (or blocks), with only one train allowed in a block at a time.

For the train crews, the dispatcher’s instructions take the form of radio messages and wayside signal lights. Radio has come to be an indispensable railroad tool, allowing complete communication among many different types of employees. The major signal systems are Automatic Block Signals (ABS) and Centralized Traffic Control (CTC). More sophisticated than ABS, CTC allows the dispatcher to control signals and track switches from a panel or computer screen, permitting greater operational flexibility. Today, a system called Positive Train Control (PTC), which utilizes computer control and GPS tracking, monitors train movement on lines transporting hazardous materials and passengers. Positive Train Control systems are designed to prevent train-to-train collisions, over-speed derailments, incursions into established work zones, and movements of trains through switches left in the wrong position.

Maintenance of rolling and fixed equipment is a big part of railroading. Among the support people are maintenance-of-way crews who work in specialized groups (rail gangs, tie gangs, etc.), bridge-and-building crews, and signal maintainers. Rolling stock is sent periodically or as needed to locomotive shops and car shops.

Today, machines do much of the work once done by people. Trackside defect detectors monitor trains for dragging and hot equipment. Most cabooses have been replaced by small boxes on the rear coupler that monitor brake line air pressure to ensure cars a coupled together. Called End-of-Train Devices (EOTD), they send a signal to the locomotive cab indicating proper coupling and air pressure. Such technological enhancements, together with the inherent efficiency of the steel-wheel-on-steel-rail format, have kept railroads vital.