A You are correct in that a conventional two-cylinder steam locomotive exhausts (“chuffs”) four times per wheel revolution. All exhausts should be equally spaced regardless of the position of the reverser, speed, and how hard the locomotive is working. You are also correct in hearing that this is not always the case. When the locomotive is new, or freshly shopped, the valves in the cylinders will have been “set” or timed by a machinist skilled at “valve setting.” If the valve-setter does a good job, the exhausts will sound “square” (90 degrees apart) no matter where the engineer places the reverser during operation.

However, it is inevitable that the various parts of the locomotive will wear over time, and they do not wear evenly. As worn conditions develop, the locomotive will no longer sound square, with one (or more) exhausts not as “crisp” as others and/or sounding “mushy.” Occasionally, this will be more pronounced in one direction than the other. Unless corrected, eventually, the locomotive will be “out of square” or “lame” and will have a difficult time starting and hauling a heavy train.

Due to the number of variables which must be taken into consideration and the various parts which must be machined or modified to fit the particular locomotive being worked on at the time, proper valve setting can be considered almost an art. – J. David Conrad, vice president and chief mechanical officer, The Valley Railroad Co.

Actually, each cylinder on each side exhausts every 180º, twice per revolution. BUT, each drive wheel is set on its axel at 90º from the one on the opposite side. Therefore, the cylinders “fire” every 90º. Hence, 2 exhaust “chuffs” per cylinder per revolution = 4 total.

I’m surprised!

Isn’t one (major!) reason for the “beats” not equally spaced the fact that the crank angle spacing on a two-cylinder engine is 120 degrees?

I’m not sure about American steam locos, but a 90 degree angle on the crank seems unusual to me.

. Another reason that the steam exhaust has a beat is that the pistons are unbalanced in area front to back.. The piston head area pushing the piston backwards is greater than the piston rod area pushing the piston forwards. So more steam is used on the greater area during the push than on the pull.

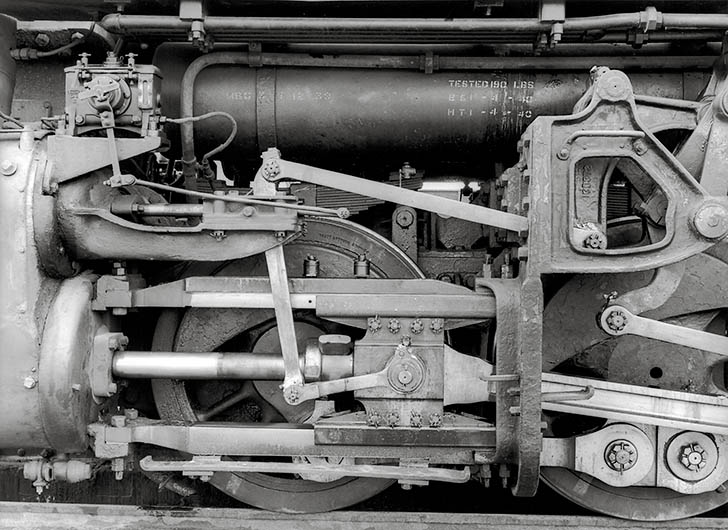

. Only a very few steam engines were built with balanced equal area. They are usually easy to recognize due to the rod sticking out the front end of the cylinder head, as well as the rod sticking out the back end. The balance rod was often covered by a sheet metal sheath. The disadvantage of the balance rod was the extra rod seal, the added moving weight, and more cooling surface area.

. – See example of balanced-piston on the front low-pressure cylinder of a Mallet at: https://veterinariancolleges.org/photo/the-baldwin-locomotive-works-1912-mallet-articulated.html

. – See foreign examples at: http://mikes.railhistory.railfan.net/r102.html

. Ultimately, the added complexity proved not worth the trouble against any added efficiency of design.