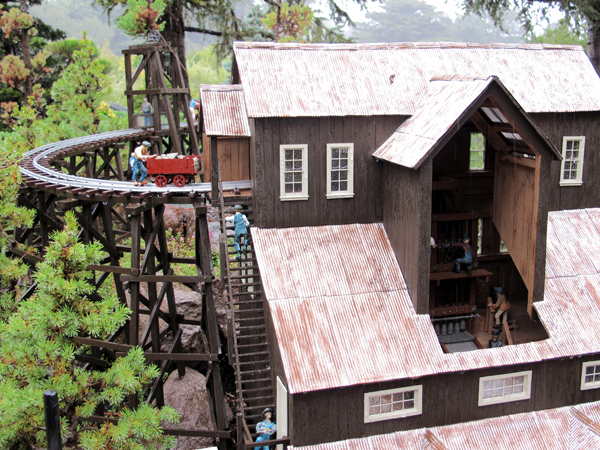

Steps and stairs suggest motion in your railway. Their zigzag architectural lines visually break up the organic pattern of nature. In gardens, these scale structures can also prevent erosion. Why not add a miniature staircase to lead us to a wonderful elevated structure and invite us to climb (although sometimes we find tired workers sitting on steps—photo 1).

Lastability

Let’s be sure the materials will hold up over the seasons. Enhance a hillside scene with stone steps sculpted from cliffs, but first beef up the area under these stairs with rebar and mortar (photo 2). Scale boards, railroad ties, or half-round logs make good steps, but need a sub-structure to prevent rain from washing them away. Paul Blondefield used scale boards, but he retained his slope as well with a substructure amid plants (photo 3). A pressure-treated board, hidden under glued and nailed scale steps, can be anchored into the ground with rebar or glued to pavers, as in photo 4. Marcus Kollmann flanked his flight of tile stairs with boulders; he then mortared the whole structure for strength, easy maintenance, and clean looks (photo 5).

Depending on your skills, choose from a range of scale materials that modelers use to get us to the top. All the photos on these pages show strong construction, with the exception of Roger Samuelsen’s scale wooden ladders in photo 9 and Ray Turner’s plastic staircases in the “Regional reports.” Luckily, staircases can be protected inside tower frames with hard bases or snugged against a building.

Full-scale steps

Don’t make “stumble stairs” within your railway. When our human muscles begin to follow a stair pattern after the second uniform step, our legs and eyes don’t have to consciously take the steps and look at the stairs—we just follow that rhythm until we reach the next platform. What if each riser and step is a different height and tread? The moment we sense a difference is the moment we stumble and must remain conscious of each step, regardless of how many train cars we’re carrying. Concrete wall blocks, for example, if stacked appropriately, would create 4-6″-high risers by 10-12″ treads. Home-improvement stores have many options for concrete steps. The trick is to make them uniform (photos 11, 11 inset).

Art in the garden

We can search online for the lowest groundcovers that you can also walk on. At stepables.com, search by zone (USDA Hardiness Zones 2-11), climate (wet or dry), exposure (sun or shade), and site preference (example: garden stairs). Why make us search for your craftsmanship under bushes when you can enhance little stairways with flat, living greenery, like sedum and thyme (photos 2-5)?

Artistically balance the vertical nature of scale stairs with a deck, a yard, or other feature. Tiny railings (photos 1, 4, 5, 9, and 10) help to protect scale figures from falling by the wayside, a sad situation. On open days, let steps and ladders present opportunities for heightened stories to be “told” (photo 10). We’ve heard heaven has a stairway! Why not “get there” within your railway?

Strong steps from good materials

Large-scale structures

• Welded steel steps, deck, and railings (photo 1)

• Sheet-metal steps on rolling stock (photo 5 and “Staff corner” in GR Links sidebar)

• Ladders on towers—plastic, metal, wood (photos 9 and 10)

• Ladders on rolling stock (photos 7 and 8)

• Wire/cable/chain railings on bridges/decks (photos 3, 5, 9, and 10)

• Tree-house ladder, cut one space wide of 1/2″ hardware cloth (photo 7)

• Rungs sunk into concrete piers or wooden retaining walls (photo 8)

Large-scale landscapes

• Tile, glued (photo 5 and Ray Turner’s Regional report)

• Slate, mortared (photo 2)

• Wooden ties or lumber, glued and nailed to a board (photos 3 and 4)

• Steps carved into wet mortar/concrete with a trowel (photo 6)

• Stepped flagstones retain hillsides or build water features (photo 6)

• Tiered cribbing or retaining walls (See “Terraces” in other sidebar)

Get a leg up with these GR links

• “Greening… Step up to terraces,” April 2009 (steps up landscaping)

• “Greening… Verticality,” April 2011 (balance steps up with flat areas)

• “Greening… Low down groundcovers,” Dec. 2010 (40 low plants)

• “Greening… Cement products,” Dec. 2014 (no-stumble stairs)

• “Plant portraits: Silver carpet,” Aug. 2012 (a 1:1 green step in a wall)

• “Staff corner… steps,” Feb. 2013 (scale walkways and steps)

• “Staff corner… coach,” Dec. 2014 (sheet-metal steps for rolling stock)

• Downloadable plans to build a 1:20.3-scale watchman’s tower plus four others (search for “tower”)

Regional gardening reports

Zones are USDA Hardiness Zones

How did you add stairs to a mine building?

Richard Murray

Milbrae, California, Zone 10

Woodworking

I had to take out about a dozen head-size rocks and about five plants to create the space for the stamp mill. I wanted an extra point of interest on the side of the mill so I decided on a set of stairs. In addition to the stairs, a door was added to the side. Unfortunately, the angle between the door on the bottom and the track on the top was quite steep, but then I figured the workers would just get some extra exercise.

The first step was to fix the placement and size of the landing outside the door. The stringers needed to be placed between the edge of the top and bottom landings. Next, to determine the spacing of the stairs, I penciled right-angle notches on a stringer. Normally, the sum of the tread and riser widths equal 17 but, with these stairs being just a model, some deviation to the rule was acceptable. Since I don’t have a bandsaw, I cut all of the right-angle notches with a razor saw. Since there needed to be two stringers, I cut both at the same time. Because these stairs were to be “open,” I left off the risers and made only treads. Finally, I attached the newel posts and railings. If you haven’t already Googled “stairs,” here is a basic primer: https://en.wikipedia.org/wiki/Stairs

Ray Turner

San Jose, California, Zone 9

Plastic above stone

The stone on the steps are from Stoneworks pieces glued into steps. The same are used to build the wall that supports the building’s overhang. The stairs up to the second-story office are commercial plastic step sections (two glued together). I added the handrails. The building—my mine and ore processing plant—is scratchbuilt from cast concrete.